Biomass particle combustion boiler system capable of realizing automatic control

A technology of biomass pellets and boilers, which is applied in the direction of controlled combustion, solid fuel combustion, and combustion methods. It can solve the problems of raw material waste, oxygen content reduction, tempering, etc., and achieve the goal of purifying the working environment, saving costs, and fully burning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

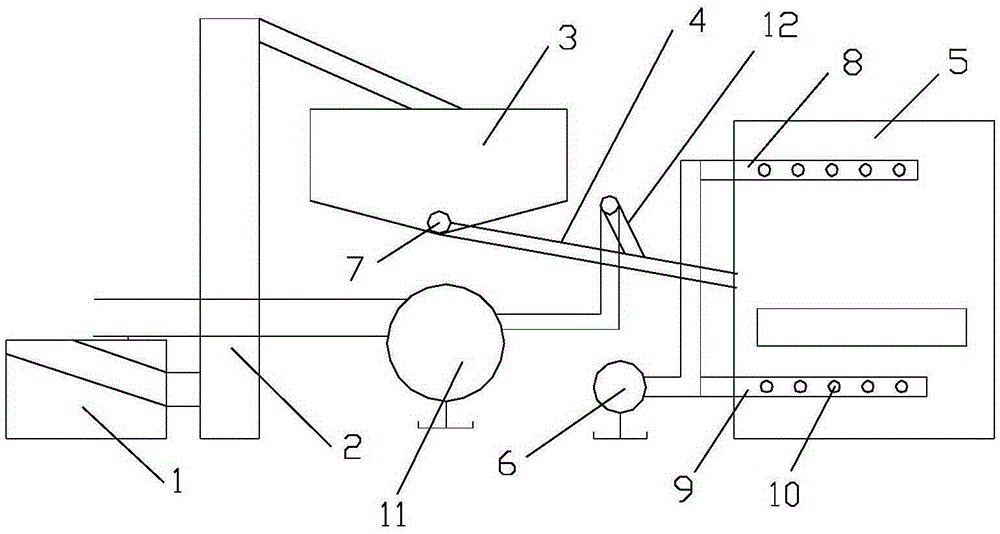

[0016] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 ;

[0017] An automatic controllable biomass particle combustion boiler system, including a PLC control box, a feeding port, the feeding port is connected to the hoist, the hoist is connected to the silo, and the silo is provided with a discharge pipe, the discharge pipe is a flat pipe, flat The feed end of the pipe is connected to the silo, the discharge end of the flat pipe is connected to the boiler and points to the grate in the boiler, and the height of the feed end is higher than the height of the discharge end. The inner material is conveyed to the feeder of the flat pipe. The feeder is controlled by the frequency conversion motor to convey the raw material to the flat pipe evenly. There is a certain angle between the flat pipe and the horizontal direction. The raw material can be transported under the action of the feeder and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com