Modified poly (propylene carbonate) and preparation method thereof

A polypropylene carbonate, modification technology, applied in the field of modified polypropylene carbonate and its preparation, can solve the problems of low tensile elongation at break, limited application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a kind of modified polypropylene carbonate and preparation method thereof, comprising the following steps:

[0031] (A) Blending polypropylene carbonate and polyphenylpolymethylene polyisocyanate, extruding to obtain crosslinked polypropylene carbonate; the polypropylene carbonate and polyphenylpolymethylene polyisocyanate The mass ratio is 100: (0.1~2);

[0032] (B) Blend the cross-linked polypropylene carbonate with poly(1,2-trimethylene adipate) and extrude to obtain modified polypropylene carbonate; the cross-linked polypropylene carbonate and polyethylene adipate The mass ratio of acid 1,2-propylene glycol ester is 100: (5~20).

[0033] In the present invention, poly(propylene carbonate) is modified by polyphenyl polymethylene polyisocyanate and poly(1,2-trimethylene adipate).

[0034] The number average molecular weight of the polypropylene carbonate is preferably 3×10 4 ~1.5×10 5 Daltons, more preferably 6 x 10 4 ~1×10 5 ...

Embodiment 1

[0042] Take the following components by weight:

[0043] Polypropylene carbonate 1000g

[0044] Polyphenylpolymethylene polyisocyanate 1g

[0045] 50 g of 1,2-trimethylene adipate having a number average molecular weight of 800.

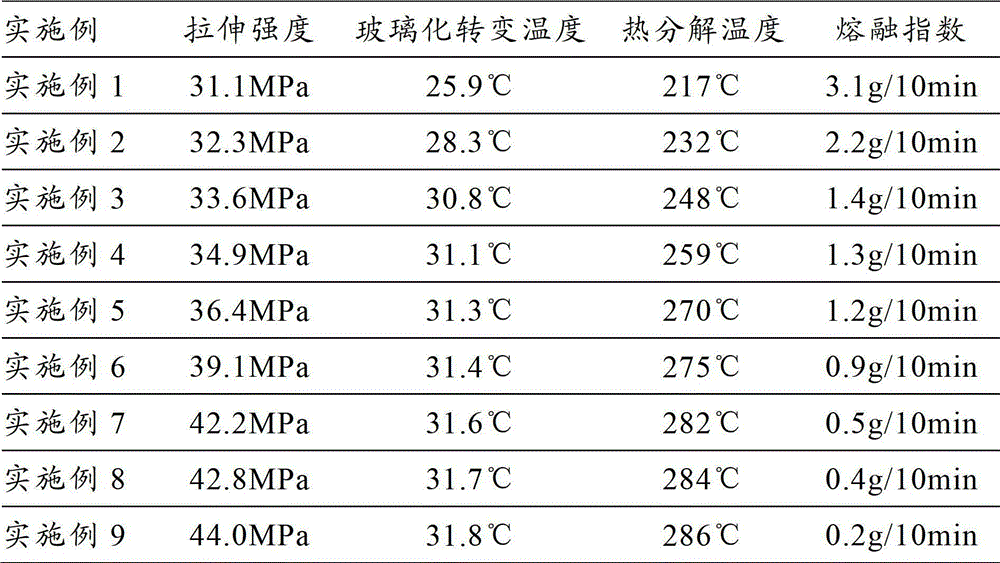

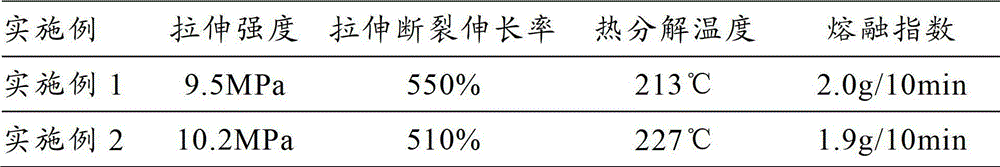

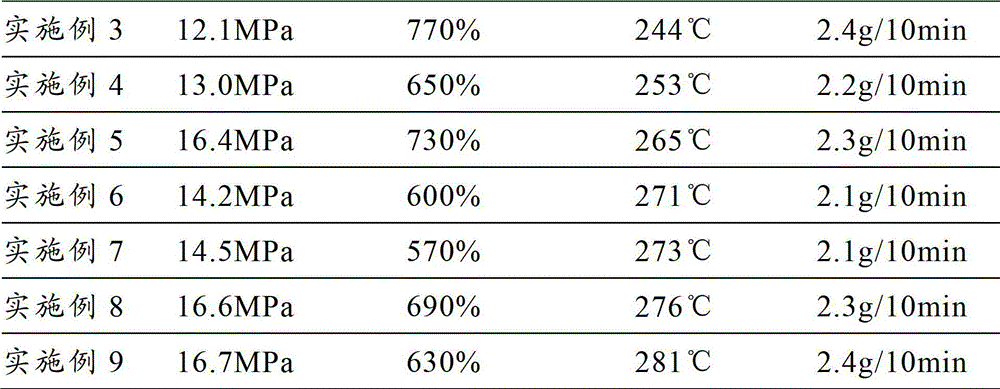

[0046] Add the above polypropylene carbonate into the mixer, add polyphenyl polymethylene polyisocyanate in the stirring state, set the temperature of the first zone of the extruder to 120°C, the temperature of the second zone to 130°C, and the temperature of the third zone to 140°C , the temperature of the fourth zone is 140°C, the temperature of the fifth zone is 140°C, the temperature of the sixth zone is 150°C, the temperature of the seventh zone is 150°C, the temperature of the eighth zone is 150°C, the temperature of the head is 145°C, and the screw speed is set to 100 rpm / min, cross-linked polypropylene carbonate is obtained after extrusion, water-cooling, stretching and granulation. The tensile strength, glass transition temperature, ther...

Embodiment 2

[0049] Take the following components by weight:

[0050] Polypropylene carbonate 1000g

[0051] Polyphenylpolymethylene polyisocyanate 3g

[0052] 50g of poly(1,2-trimethylene adipate) with a number average molecular weight of 3000

[0053] Add the above polypropylene carbonate into the mixer, add polyphenyl polymethylene polyisocyanate in the stirring state, set the temperature of the first zone of the extruder to 125, the temperature of the second zone to 135°C, and the temperature of the third zone to 145°C. The temperature in the fourth zone is 145°C, the temperature in the fifth zone is 145°C, the temperature in the sixth zone is 155°C, the temperature in the seventh zone is 155°C, the temperature in the eighth zone is 155°C, the temperature of the head is 150°C, and the screw speed is set to 130 rpm , cross-linked polypropylene carbonate is obtained after extrusion, water-cooling, stretching and granulation. The tensile strength, glass transition temperature, thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com