Kieselguhr template carbon with large specific surface area and high pore volume and preparation method thereof

A technology with large specific surface area and diatomite, applied in the preparation/purification of carbon, etc., can solve the problems of poor adsorption capacity, difficulty in popularization and application of diatomite-based porous carbon, low specific surface area and total pore volume, etc. Effect of Micropore Volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Weigh 1g of Jilin diatomite raw material purified by sedimentation (the main diatom species of which is diatoms of the order Diatomaceae) at room temperature and add it to 5ml of furfuryl alcohol, and then add 0.1g of oxalic acid to form a suspension. The resulting suspension was fully stirred for 1 hour; then placed in a vacuum drying oven, heated to 95° C. under vacuum, and a solid product was obtained after constant temperature for 2 hours.

[0026] 2) Put the above product in a tube furnace, raise the temperature to 700° C. under a nitrogen atmosphere, and keep the temperature constant for 3 hours to obtain a diatomite-carbon composite without removing the template. Then the nitrogen purging was stopped, and water vapor was introduced, and activated at a constant temperature of 700° C. for 1 hour, cooled to room temperature, and pulverized to obtain an activated solid.

[0027] 3) Add 1 g of the activated solid into 10 ml of 40% hydrofluoric acid solution by volu...

Embodiment 2

[0031] 1) Weigh 1g of Jilin diatomite raw material purified by sedimentation (the main diatom species of which is diatoms of the order Diatomaceae) at room temperature and add it to 5ml of furfuryl alcohol, and then add 0.1g of oxalic acid to form a suspension. The resulting suspension was fully stirred for 1 hour; then placed in a vacuum drying oven, heated to 95° C. under vacuum, and a solid product was obtained after constant temperature for 2 hours.

[0032] 2) Put the above product in a tube furnace, raise the temperature to 700° C. under a nitrogen atmosphere, and keep the temperature constant for 3 hours to obtain a diatomite-carbon composite without removing the template. Then the nitrogen purge was stopped, and CO 2 , and activated at a constant temperature of 700 ° C for 1 hour, cooled to room temperature, and pulverized to obtain an activated solid.

[0033] 3) Add 1 g of the activated solid into 10 ml of 40% hydrofluoric acid solution by volume, and stir thoroughl...

Embodiment 3

[0037] This embodiment is basically the same as Embodiment 2, except that it is activated for 2 hours under a carbon dioxide atmosphere, and other steps are the same.

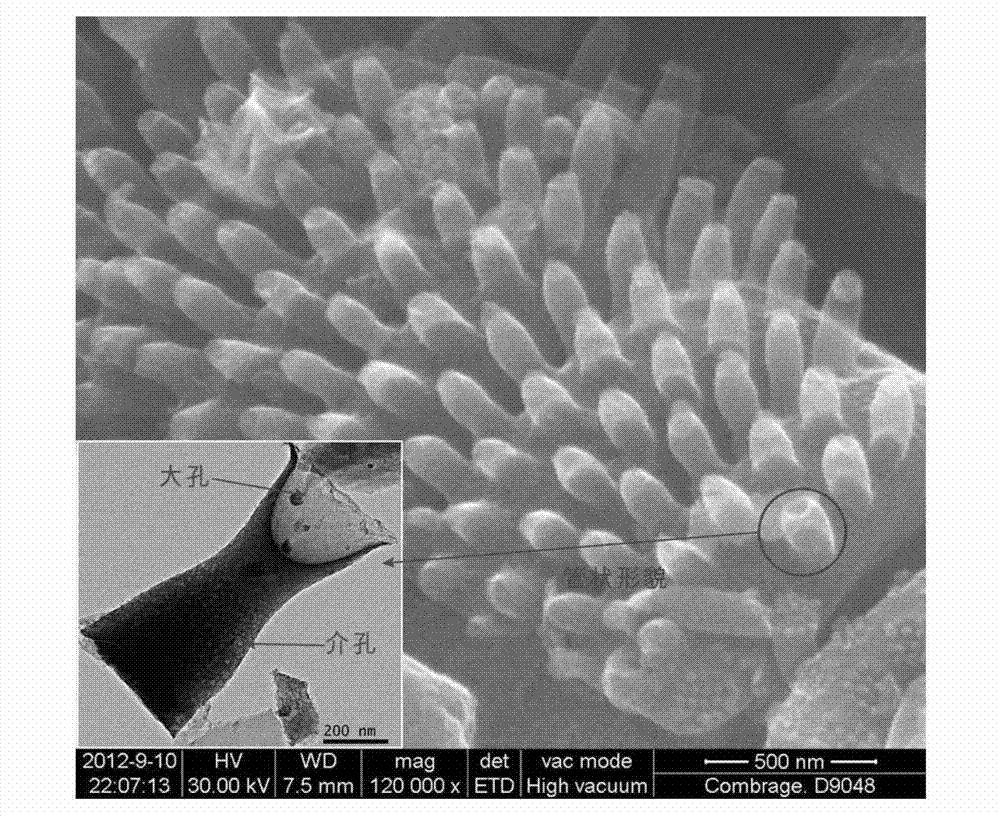

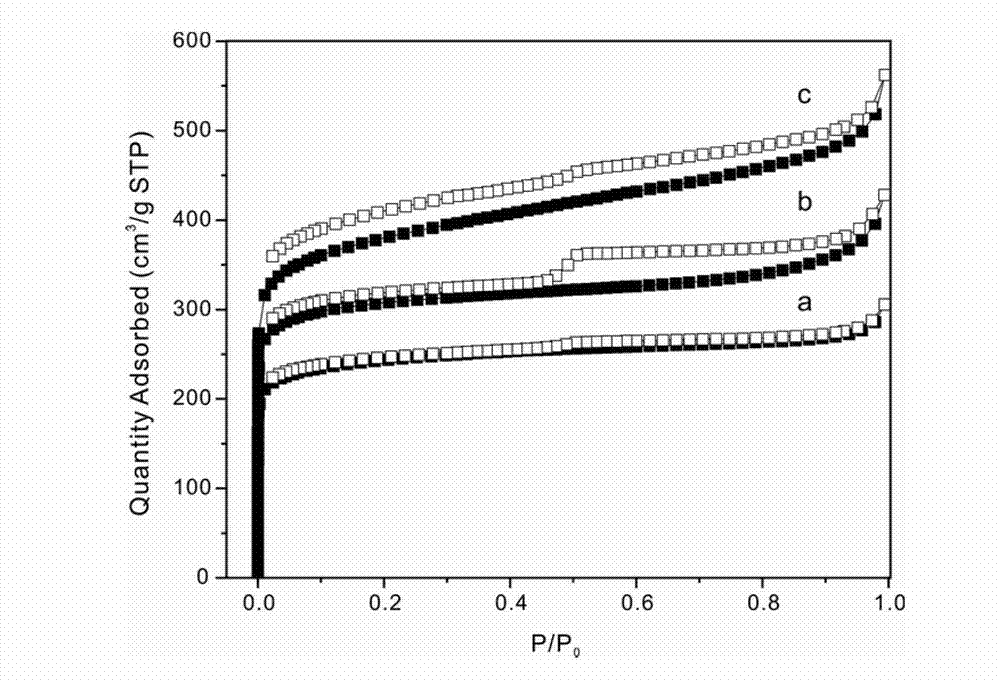

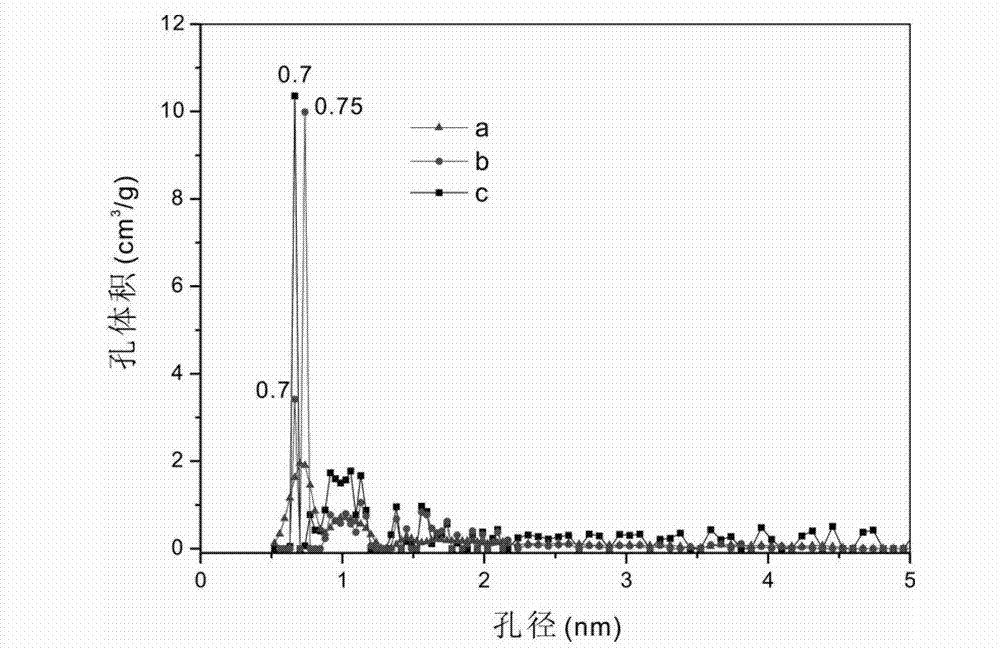

[0038] Through high-resolution scanning electron microscope observation, it is found that the obtained diatomite template carbon replicates the densely arranged tubular morphology of diatomite. Through transmission electron microscope observation, it is found that it has a macroporous tubular structure, and there are abundant mesopores and micropores on the surface of the tube wall. The specific surface area of the large specific surface area and high pore volume diatomite template carbon obtained in this example is 1275m 2 / g, the total pore volume is 0.797cm 3 / g, the micropore volume is 0.321cm 3 / g( figure 2 in c), the micropore pore sizes are concentrated at ~0.7 and 1 nm ( image 3 in c).

[0039] As an application, the ability of the large specific surface area and high pore volume diatomite temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com