Deburring machine tool

A deburring and machine tool technology, which is applied to the parts of grinding machine tools, grinding machines, and machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems that affect the quality of parts reprocessing and difficult to remove burrs, and achieve the goal of improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

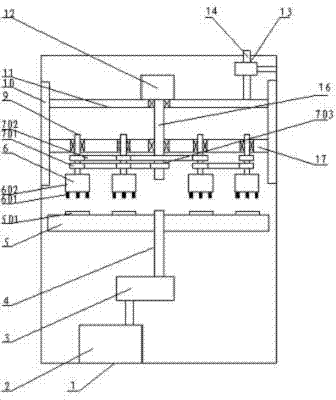

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

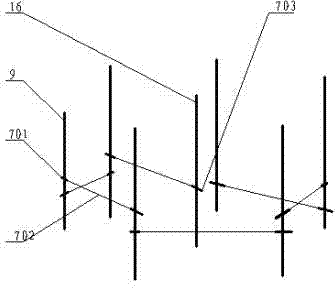

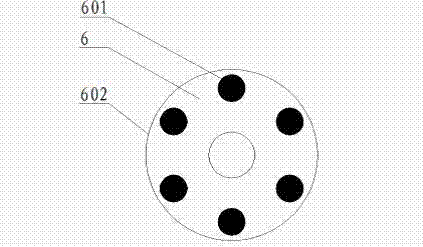

[0029] figure 1 Shown is a schematic structural view of the deburring machine tool of the present invention, including a casing 1, a first working disk 5 is built inside the casing 1, the first working disk 5 is fixedly connected to the first driving shaft 4, and the first driving shaft 4 is connected to the On the first motor 2, a number of workpiece clamping discs 501 are evenly distributed on a circle of the upper surface of the first working disc 5, and there is also a horizontal position above the first working disc 5 that is connected to the inside of the casing 1 and whose vertical position is adjustable. The second working disk 17, the lower surface of the second working disk 17 is equipped with a number of rotatable brushes 6, the brushes 6 include a number of brush filaments 601 and a clamping cylinder 602 for clamping the brush filaments 601, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com