Pipeline facing machine

A technology of pipe beveling machine and casing, which is applied in the direction of metal processing machinery parts, clamping, support, etc., which can solve the problems of insufficient equipment strength, high manual labor intensity, falling and breaking of the machine, etc., and achieve an increase in volume-to-power ratio , Reduce labor intensity, strong and continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

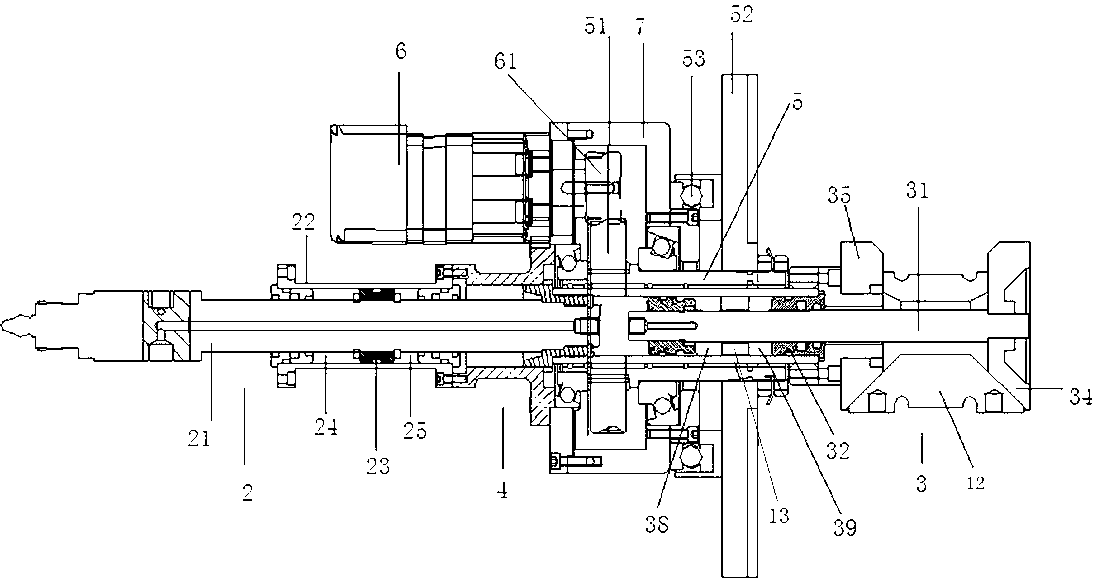

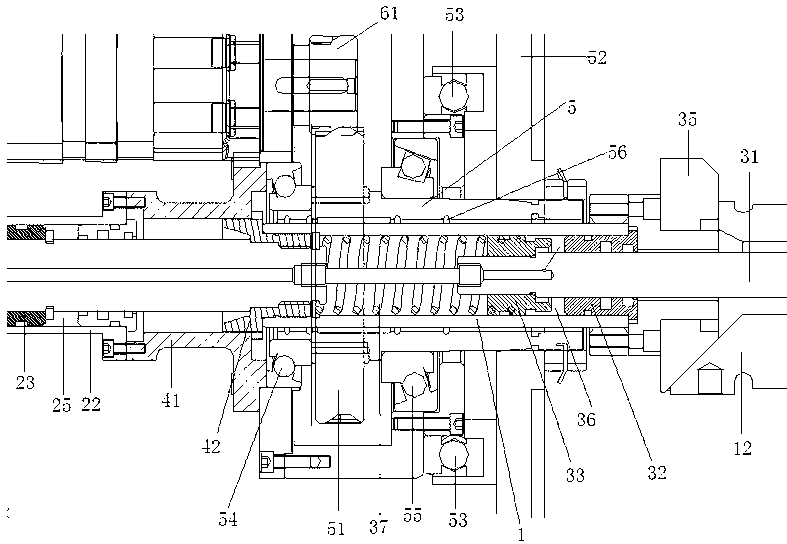

[0053] The present invention will be described below with reference to the accompanying drawings.

[0054] Insert the hydraulic tightening and braking device of the hydraulic tensioning device 3 into the pipeline 8, inject pressure oil into the fourth chamber 38, the seal 33 moves toward the hydraulic cutting and feeding device, and tighten the main shaft (piston rod) 31 at the same time Move toward the hydraulic cutting feeding device direction, because the pull block 34 is fixed on the tensioning main shaft 31, the pull block 34 moves toward the support block 35 direction, and at this moment, the inclined block 12 moves along the pull block 34 and the support block 35. The chute protrudes outward until the surface of the inclined block 12 (or the claw installed on the inclined block) contacts and expands the inner wall of the pipe 8. After the inclined block 12 is expanded, the pipe beveling machine is fixed on the end surface of the pipe 8 Above, after the pipe beveling mac...

Embodiment 2

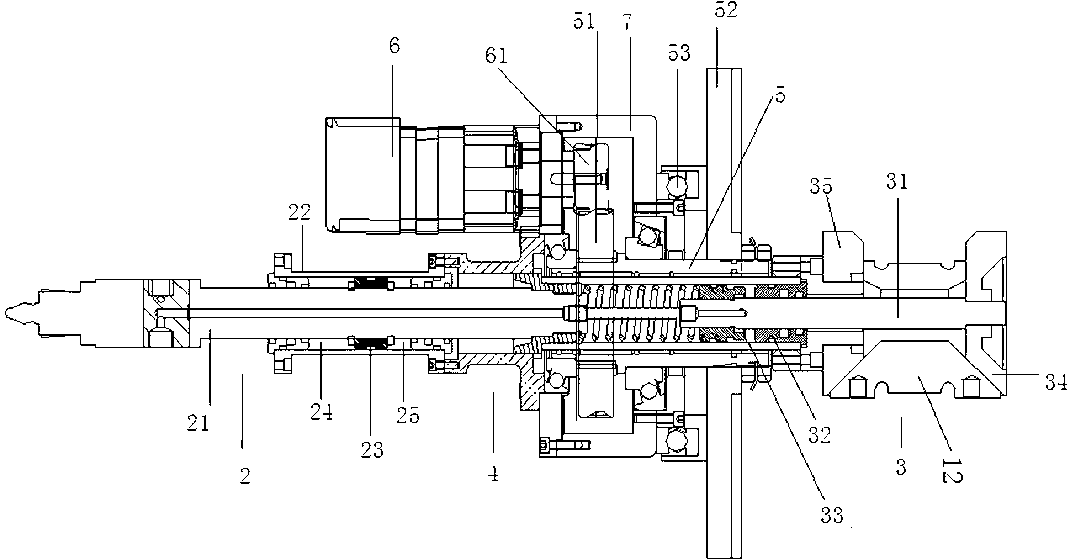

[0056] See attached below figure 2 The present invention is described with reference to the drawings.

[0057] Insert the hydraulic tensioning brake device of the hydraulic tensioning device 3 into the pipeline 8, inject the pressure oil into the fifth chamber 36, the seal 33 moves towards the hydraulic cutting feeding device, and the main shaft 31 is tightened to feed the hydraulic cutting at the same time Move in the device direction, because the pull block 34 is fixed on the tension main shaft 31, the pull block 34 moves toward the support block 35 direction, at this moment, the inclined block 12 stretches out along the chute on the pull block 34 and the support block 35 until the surface of the inclined block 12 is in contact with the inner wall of the pipe 8 and tightened, the pipe beveling machine is fixed on the end face of the pipe 8 after the inclined block 12 is expanded, and the driving device 6 works after the pipe beveling machine and the pipe are fixed. The pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com