Collecting agent for copper converter slag flotation and use method thereof

A technology of copper converter slag and collector, which is applied in the field of efficient and comprehensive utilization of resources, can solve the problems of lower collection capacity than xanthate, large amount of collector, and low grade of copper concentrate, so as to reduce the dosage of chemicals and collect Strong ability, the effect of reducing the comprehensive dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

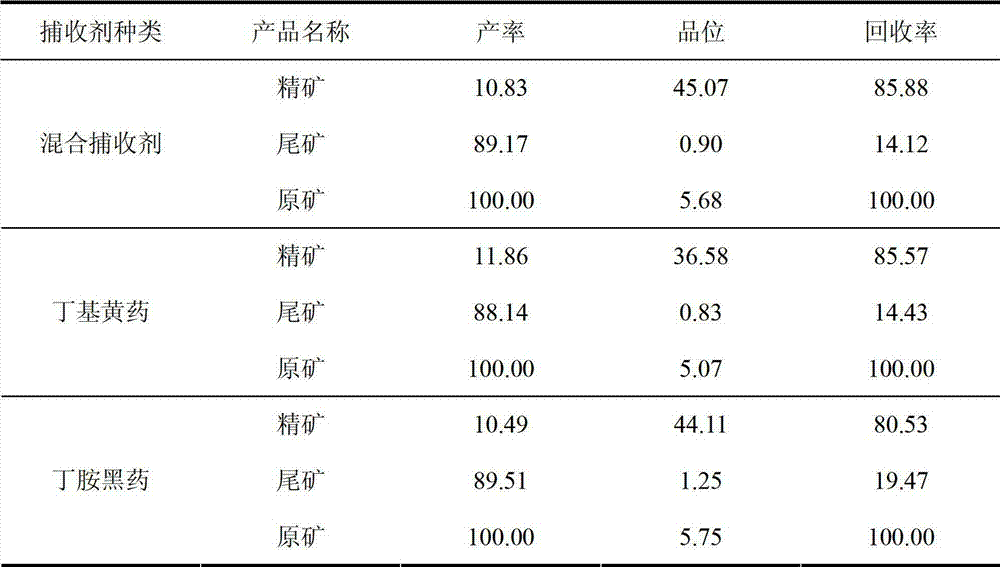

[0024] A comparison method is used to verify the effectiveness of the mixed collector provided by the invention for flotation of copper converter slag. The comparative example is a single butyl xanthate and butylamine black drug collector. The test process is one-stage grinding and one-stage roughing, and the dosage of the three collectors is 100g / t. The test results are shown in Table 1.

[0025] Table 1 Comparative test results / %

[0026]

[0027] As can be seen from the results, when a single butylxanthate was used as a collector, the rougher concentrate grade was lower and the recovery rate was higher; while a single butylamine black drug was used as a collector, the rougher concentrate grade was lower. high and low recovery. The mixed collector provided by the invention can effectively improve the concentrate grade without affecting the recovery rate.

Embodiment 2

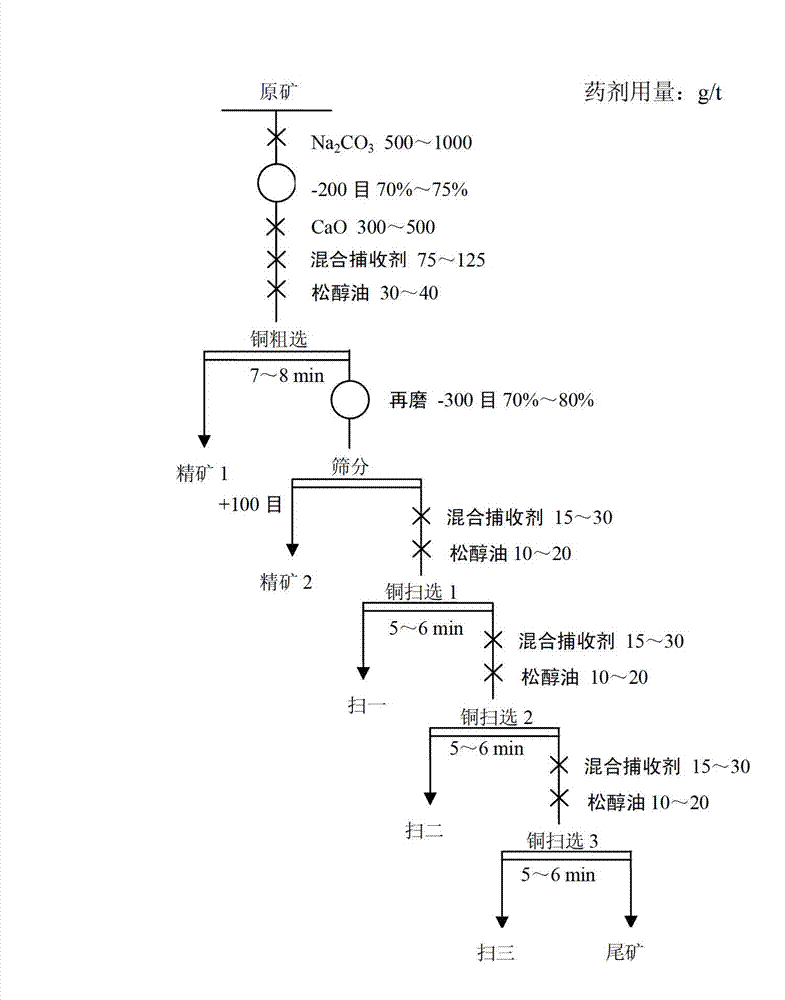

[0029] Adopt a kind of collector that is used for copper converter slag flotation provided by the present invention, carry out flotation open-circuit test to Daye copper converter slag, the technological process that test adopts sees figure 1 . The test results are shown in Table 2.

[0030] Table 2 Copper converter slag open circuit test results / %

[0031]

[0032]

[0033] It can be seen from the results that the copper concentrate grade after the combination of concentrate 1 and concentrate 2 reaches 39.44%, the recovery rate is 87.72%, the recovery rate of concentrate plus medium ore is 95.19%, and the tailings grade is only 0.35%.

Embodiment 3

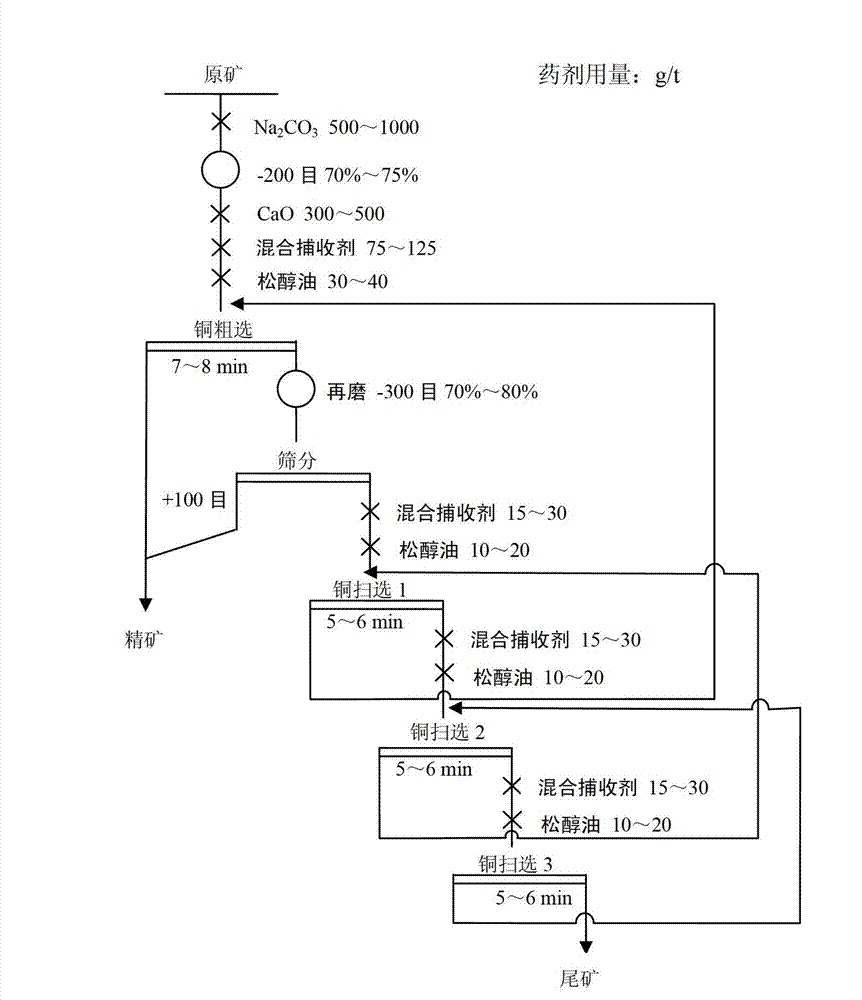

[0035] In order to eliminate the influence of difficulties in middling flotation separation, a small-scale closed-circuit test was carried out on Daye copper converter slag. The process flow used in the test is shown in figure 2 . The test results are shown in Table 3.

[0036] Table 3 Small-scale closed-circuit test results of copper converter slag / %

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com