Nanometer cyclophosphamide and preparation method thereof

A cyclophosphamide, nano-level technology, applied in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., can solve the problem of low bioavailability, poor absorption, and insoluble cyclophosphamide. Water and other problems, to achieve the effect of low cost and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

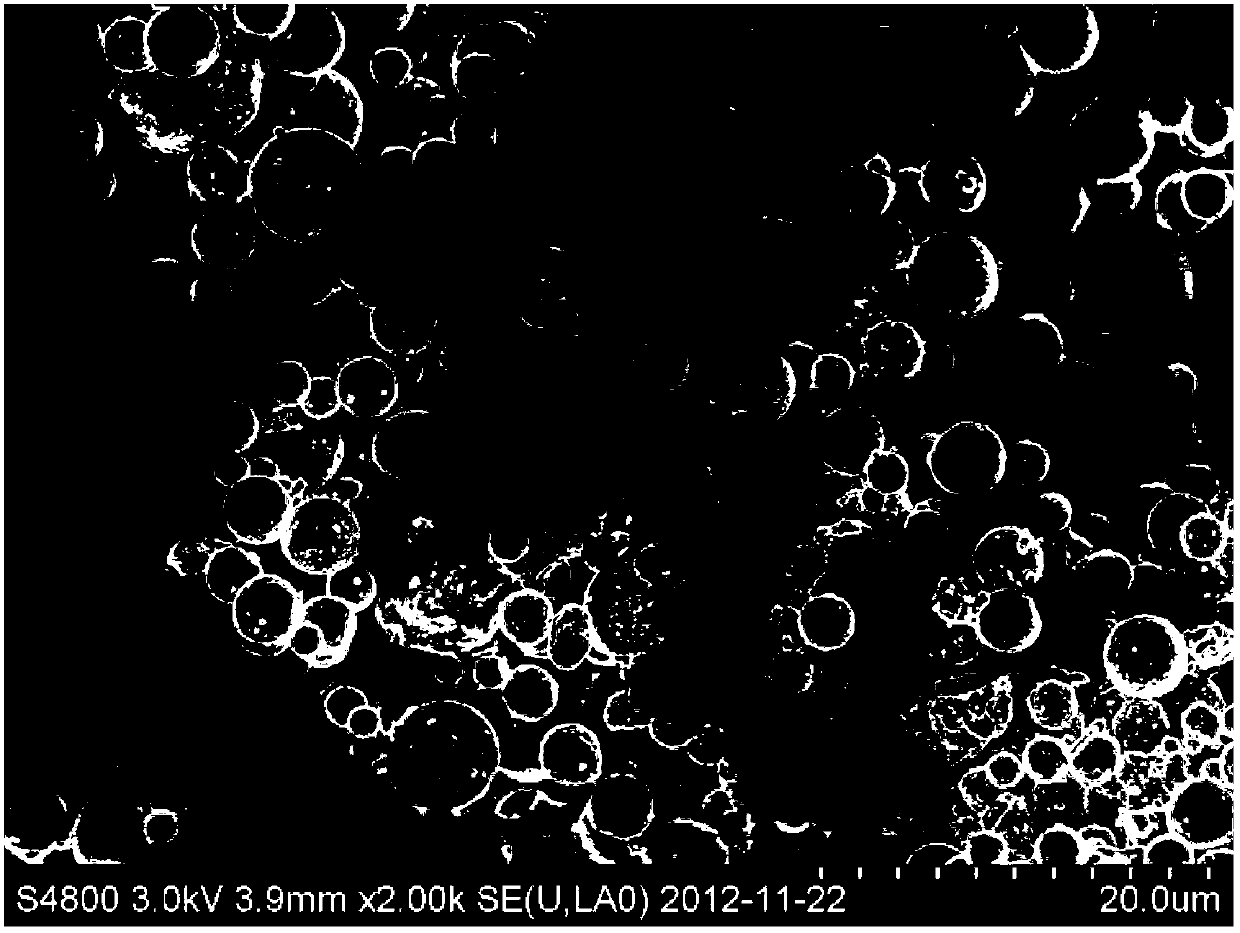

Image

Examples

Embodiment 1

[0061] The nanoscale cyclophosphamide of the present embodiment is prepared according to the following method:

[0062] 1. Cyclophosphamide API (Hubei Haiboyuan Chemical Co., Ltd.) 1g, add 20ml of absolute ethanol to dissolve;

[0063] 2. Add 2g of silica airgel after heat treatment at 500°C for adsorption;

[0064] 3. After the adsorption is complete, dry it in an oven at 60°C;

[0065] 4. After drying, add 100ml of pure water and emulsify with 25000rpm / min ordinary emulsifier for 5min;

[0066] 5. High-pressure homogenizer (Shanghai Donghua GYB 30-6S), 400bar, cycle 6 times, 10min;

[0067] 6. Spray-dry the homogeneous liquid in an experimental spray dryer (Shanghai Shunyi Technology SP-1500), parameters: temperature 130°C, flow rate 500ml / h, nozzle: 0.75mm, and obtain nano-scale cyclophosphamide particles after drying.

Embodiment 2

[0069] The nanoscale cyclophosphamide of the present embodiment is prepared according to the following method:

[0070] 1. Cyclophosphamide API (Hubei Haiboyuan Chemical Co., Ltd.) 1g, add 5ml of absolute ethanol to dissolve;

[0071] 2. Add 0.5g of silica airgel after heat treatment at 1000℃ for adsorption;

[0072] 3. After the adsorption is complete, dry naturally;

[0073] 4. After drying, add 20ml of pure water and emulsify with an ordinary emulsifier at 25000rpm / min for 5min;

[0074] 5. High pressure homogenizer (Shanghai Donghua GYB 30-6S), 400bar, cycle 8 times, 10min;

[0075] 6. Spray-dry the homogeneous liquid in an experimental spray dryer (Shanghai Shunyi Technology SP-1500), parameters: temperature 130°C, flow rate 500ml / h, nozzle: 0.75mm, and obtain nano-scale cyclophosphamide particles after drying.

Embodiment 3

[0077] The nanoscale cyclophosphamide of the present embodiment is prepared according to the following method:

[0078] 1. Cyclophosphamide API (Hubei Haiboyuan Chemical Co., Ltd.) 1g, add 150ml of absolute ethanol to dissolve;

[0079] 2. Add 15g of hydrophilic silica airgel for adsorption;

[0080] 3. After the adsorption is complete, freeze-dry;

[0081] 4. After drying, add 150ml of pure water and emulsify with 25000rpm / min ordinary emulsifier for 5min;

[0082] 5. High-pressure homogenizer (Shanghai Donghua GYB 30-6S), 400bar, cycle 7 times, 10min;

[0083] 6. Spray-dry the homogeneous liquid in an experimental spray dryer (Shanghai Shunyi Technology SP-1500), parameters: temperature 130°C, flow rate 500ml / h, nozzle: 0.75mm, and obtain nano-scale cyclophosphamide particles after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com