Greenhouse circulating type heating furnace

A circulating heating furnace technology, which is applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of low efficiency, less heat exchange, and large floor space, and achieve simple heating methods, improved heating efficiency, and small footprint small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

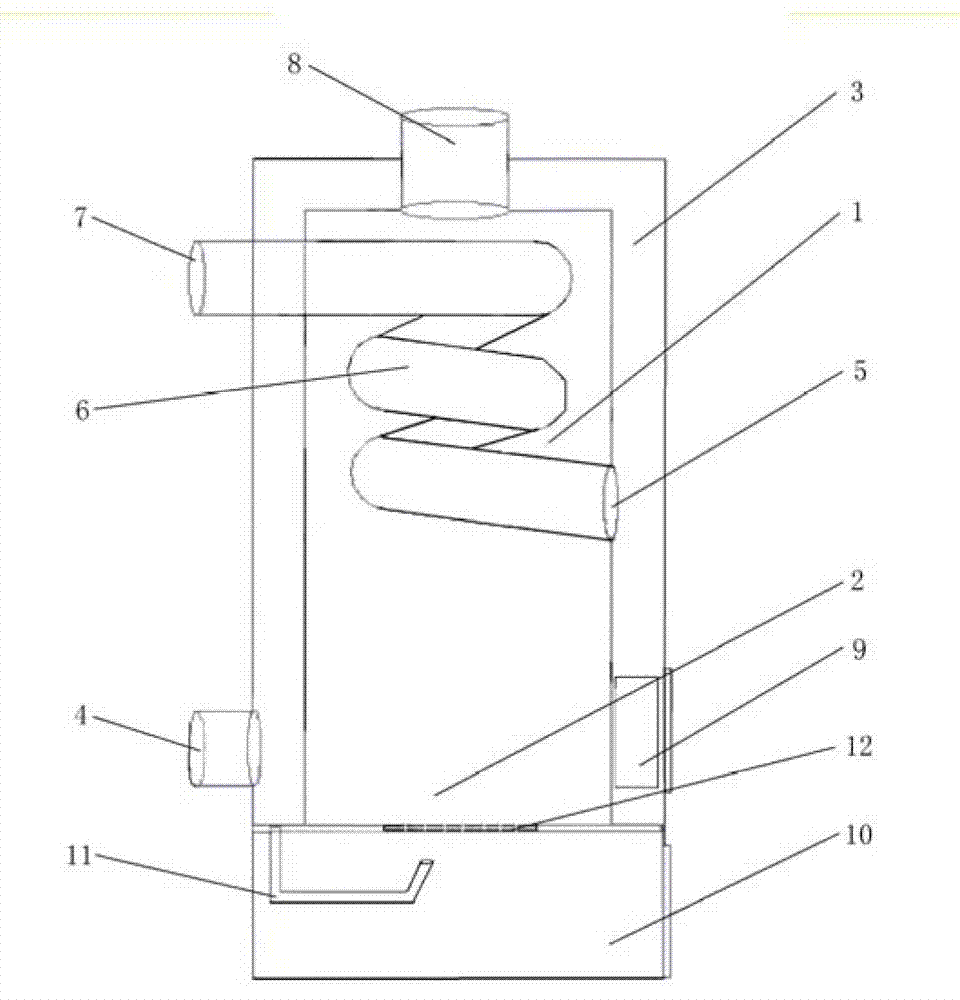

Embodiment 1

[0029] This embodiment is a greenhouse circulating heating furnace that adopts coal combustion heating, including a furnace body 1 and a combustion chamber 2. The furnace body 1 has a height of 800mm and a width of 400mm, and is small in size and suitable for use in greenhouses. The shell 3 of the furnace body 1 is a double-layer hollow structure with an interlayer thickness of 50 mm. The outer shell wall on one side of the shell has an outer air inlet 4 with a diameter of 75 mm, and the inner shell wall on the other side has an inner air inlet. The tuyere 5, the inside of the furnace body 1 includes a temperature-resistant steel pipe 6, the steel pipe 6 is coiled 3 times in the furnace body 1, one end is connected to the inner air inlet 5, and the other end is connected to the outside through the outer shell 3 through the air outlet 7. A 150-watt blower is continuously used at the outer air inlet 4 to input cold air into the hollow shell 3 of the body of heater, and the cold a...

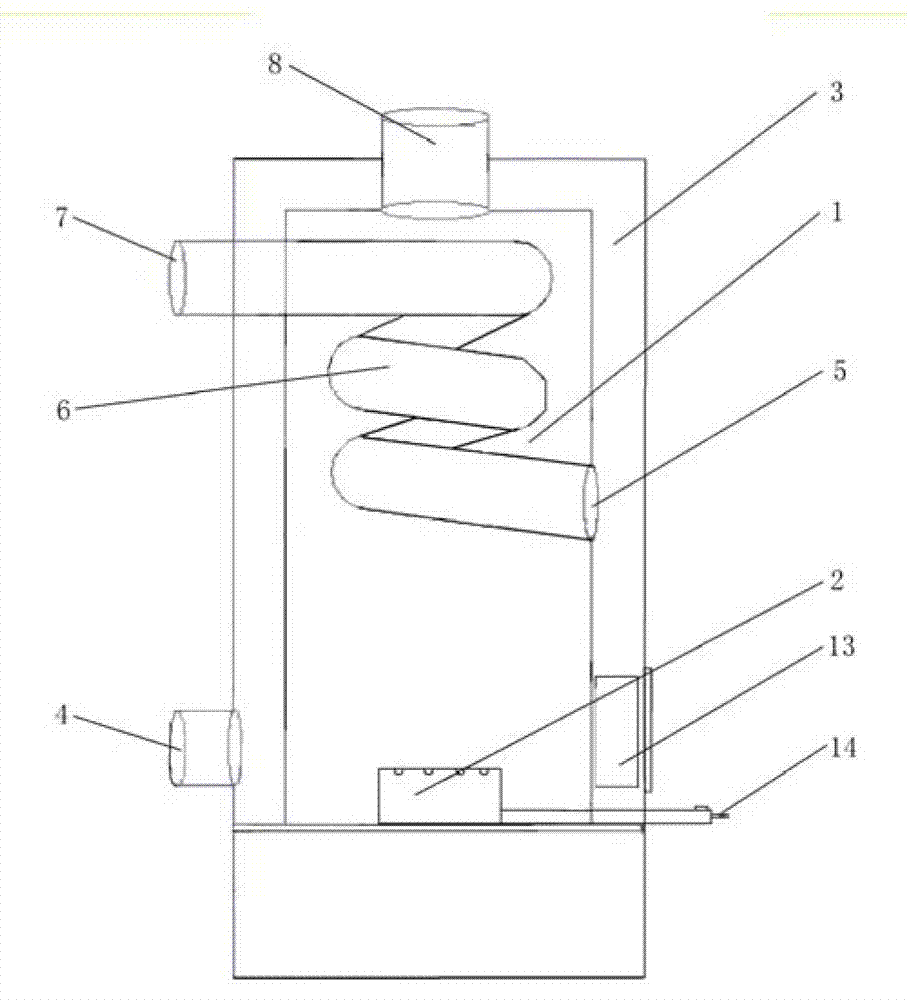

Embodiment 2

[0032] This embodiment is a greenhouse circulating heating furnace that adopts gas combustion heating. The furnace body 1 and the shell 3 are basically the same as those of Embodiment 1. The position of the combustion chamber 2 is provided with a gas connection 14, and above the gas connection 14, an observation port 13 for conveniently observing the combustion situation is provided.

[0033] The use of gas combustion heating can not only achieve the purpose of efficient heating and temperature increase, but also has cleaner energy, simpler equipment and lower costs.

[0034] This embodiment can also be applied to biogas combustion for heat supply.

[0035] From 2011 to 2012, the Beijing Municipal Extension Station and Beijing Yuanfengtai Agricultural Planting Cooperative conducted a test using the equipment of the above embodiment in Xishaoqu Village, Xishaoqu Town, Miyun. Mu increased by 2010 kg compared with the control, zucchini increased by 1815.5 kg per mu compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com