Cylinder liner with high strength and wear resistance and manufacturing method thereof

一种气缸套、高强度的技术,应用在汽缸、汽缸盖、制造工具等方向,能够解决强度和耐磨性差、不能满足大功率发动机机器节能、降耗、减排的发展要求等问题,达到克服耐腐性差、性能优越、好耐磨性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] High-strength wear-resistant cylinder liner, its weight percentage is composed of (%):

[0030] C: 3.25, Si: 2.25, P: 0.35, S: 0.08, Mn: 0.5, Mo: 0.2, Nb: 0.082, and the balance is Fe.

[0031] The preparation method is as follows:

[0032] Centrifugal casting: the casting temperature is 1380°C, and the centrifuge speed is 1360 rpm.

[0033] Machining: The cylinder liner blank is processed into a semi-finished product, with a margin of 0.5mm in the inner hole and outer circle; the thickness of the cylinder wall on one side of the semi-finished product is 8mm, and the pre-cooling time is 36 seconds.

[0034] Heat treatment: Put the cylinder liner in a controlled atmosphere furnace at 920°C for 1.5 hours to austenitize, then quench it into a salt bath composed of 50% potassium nitrate + 50% sodium nitrate, hold it at 340°C for 75 minutes; Fire 2h.

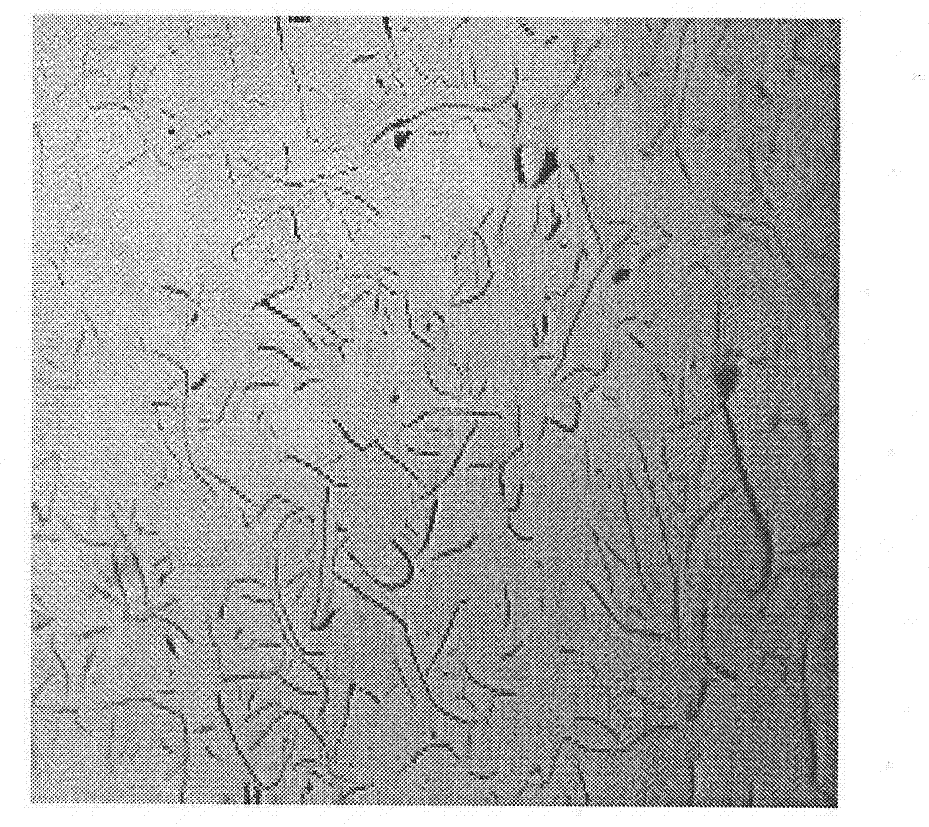

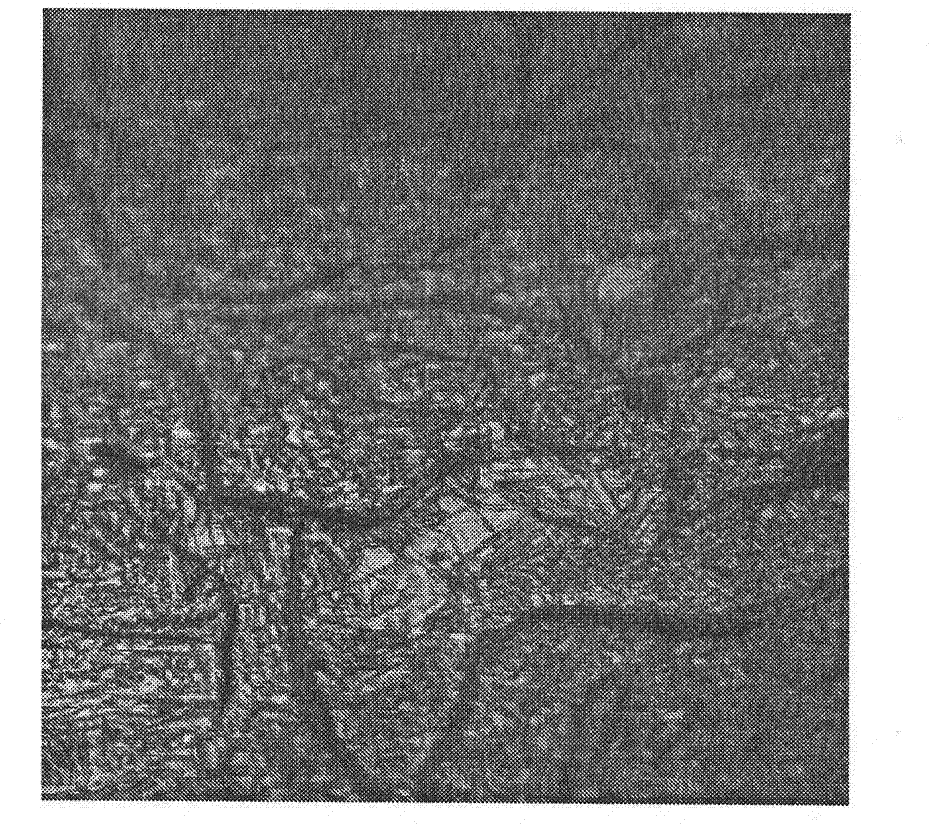

[0035] It can be seen from Figure 1-3 that the obtained cylinder liner structure is acicular ferrite and carbon-rich aust...

Embodiment 2

[0037] High-strength wear-resistant cylinder liner, its weight percentage is composed of (%):

[0038] C: 3.2, Si: 2.15, P: 0.35, S: 0.07, Mn: 0.35, Mo: 0.26, Nb: 0.12, and the balance is Fe.

[0039] The preparation method is as follows:

[0040] Centrifugal casting: the casting temperature is 1400°C, and the centrifuge speed is 1380 rpm.

[0041] Machining: Process the cylinder liner blank into a semi-finished product, leaving 0.5mm allowance for the inner hole and outer circle.

[0042] Heat treatment: Put the cylinder liner in a controlled atmosphere furnace at 920°C for austenitization for 100 minutes, then quench it into a salt bath composed of 50% potassium nitrate + 50% sodium nitrate, hold it at 330°C for 85 minutes; then temper at 180°C at low temperature 2h.

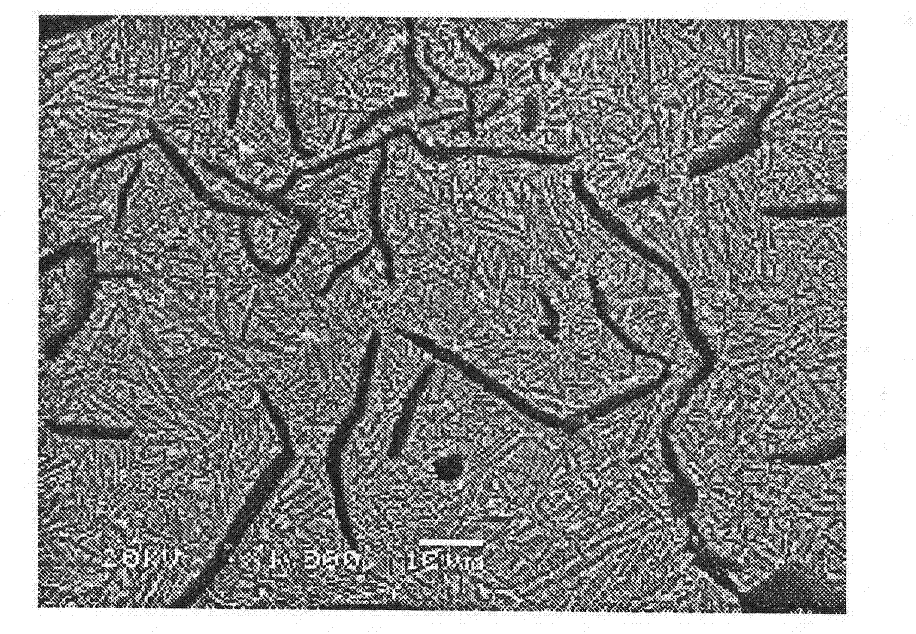

[0043] It can be seen from Figure 4-6 that the obtained cylinder liner structure is acicular ferrite and carbon-rich austenite. Under the condition of magnification of 100 times, the length of graphite is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com