Optical phase conductor (OPPC)

A technology of optical fiber composite and phase wire, which is applied in the direction of power cables, electrical components, and power cables with shielding layers/conductive layers, etc., can solve problems such as short-circuit current overheating, cable broken faults, lightning strikes and broken strands, etc., to achieve performance matching, Good thermal stability, the effect of optimized configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

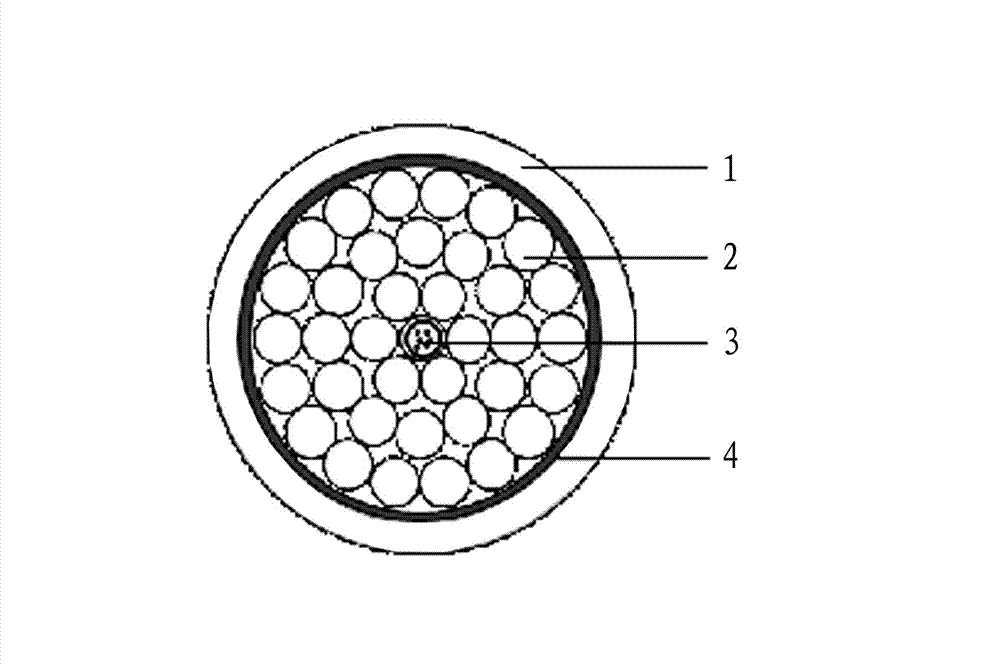

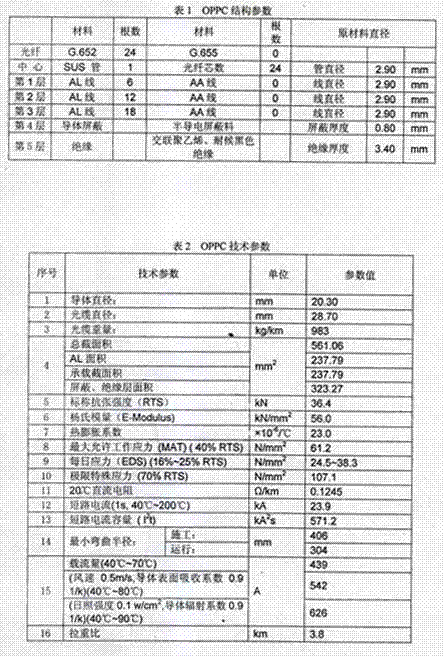

[0017] Such as figure 1 As shown, the present invention is a new type of optical fiber composite overhead phase line, which is used in 10kV power transmission lines and is composed of optical fiber unit 3, hard aluminum wire 2, conductor shielding layer 4 and insulating layer 1. The outside of the optical fiber unit 3 is coated with a hard aluminum wire 2 , and the outer layer of the hard aluminum wire 2 is a conductor shielding layer 4 and an insulating layer 1 in sequence.

[0018] In order to match the new optical fiber composite overhead phase line OPPC with the wire structure, mechanical properties and electrical properties of Huishan Line, and meet the requirements of line communication, OPPC adopts a central tube structure, 24-core G.652 optical fiber and stainless steel tube to form an optical fiber unit 3, The diameter of the steel pipe is 2.90mm.

[0019] The optical fiber unit 3 is covered by three layers of hard aluminum wires 2, each with a diameter of 2.90mm. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com