Central outside-vein house pillar type combined crosscut two-end inside-vein continuous segment filling mining method

A backfill mining method and room-and-pillar technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of resource waste, high ore loss and dilution rate, mountain caving, etc., and achieves high degree of mechanization and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

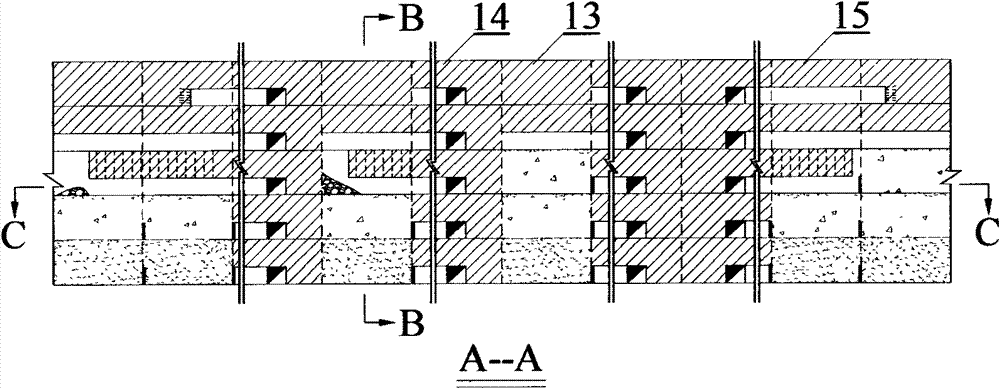

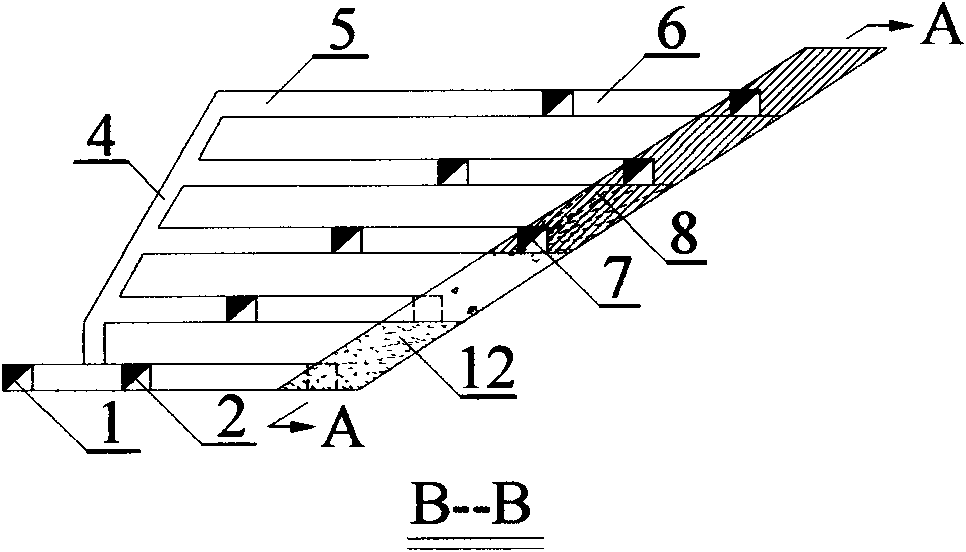

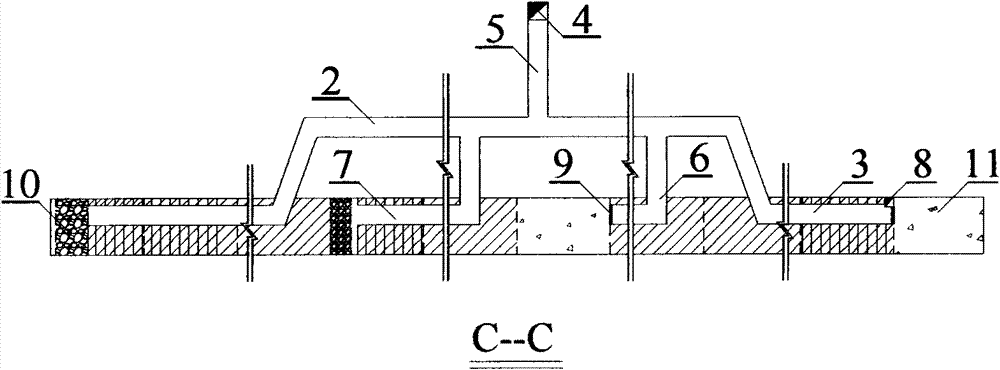

[0026] Example Take a stope of the Shaba mine used by Guizhou Kailin Group Mining Corporation as an example.

[0027] The current mining range of Yongshaba Mine is +920~+1120m. The thickness of the ore bed is relatively stable in the strike direction, and the strike length is nearly 3800m; the average true thickness of the ore body is 6.5m, and the average dip angle is 32°; the average ore grade is 35.66% and the bulk density is 2.78 t / m 3 , Phosphate ore reserves A+B+C+D grade 27.232 million tons. The boundary between the ore layer and the surrounding rock of the roof and floor is clear. The direct roof is an unstable layer produced by carbonate and silicate rocks, the indirect roof is dolomite, and the direct floor of the ore layer is quartz sandstone or red shale. The specific implementation steps are as follows:

[0028] 1. Divide the ore body into panels along the strike, the panel length is 800m, the vertical height is 50m, and the subsection vertical height is 10m; the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com