Bypass short joint capable of being activated and circulated repeatedly

A sub-joint, radial through-hole technology, applied in wellbore/well valve devices, wellbore/well components, earth-moving drilling, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

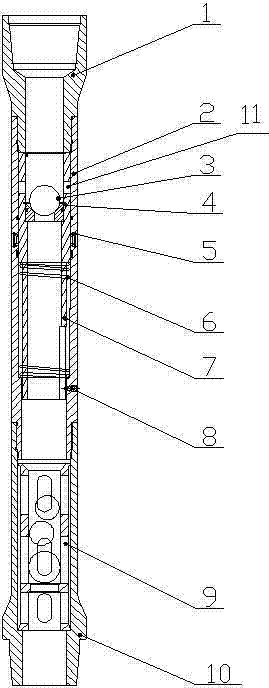

[0012] Embodiment 1: refer to figure 1 , a bypass nipple that can be activated multiple times, including an upper and lower joint 1, a lower joint 10, a body 2, a rubber ball 3, and a steel ball. The upper part of the main body 2 pipe wall is symmetrically provided with two nozzles 5, and the lower part is provided with positioning A pin 8, a sliding sleeve 7 is provided in the inner cavity of the body 2, a spring 6 is provided below the sliding sleeve 7, a ball seat 4 is arranged in the sliding sleeve 7, and two radial through holes 11 are arranged symmetrically on the pipe wall; the lower end of the sliding sleeve 7 When the positioning pin 8 is in position, the radial through hole 11 on the sliding sleeve 7 is aligned with the nozzle 5 of the body 2; the lower joint 10 is also provided with a ball basket 9; the outer diameter of the rubber ball 3 is greater than the inner diameter of the ball seat 4, and the steel The outer diameter of the ball is smaller than the inner dia...

Embodiment 2

[0013] Embodiment 2: refer to figure 1 , a bypass nipple that can be activated multiple times, on the basis of the structure of embodiment 1, it also includes the following structure: the ball basket 9 is provided with a righting wing, and the length of the ball basket 9 can be used for six repeated pitches Open the bypass circulation, and the rubber ball 3 is a polyvinyl rubber ball.

[0014] The specific working process is as follows: during drilling, well completion or workover operations, the bypass nipple of the present invention is connected to the drill pipe for standby. When it is necessary to deal with lost circulation or well cleaning, put in a polyethylene-based rubber ball 3, and after the pump is turned on, the rubber ball 3 is seated at the ball seat 4, and the pressure drives the sliding sleeve 7 to compress the spring 6 to slide downward, and the sliding sleeve 7 The position is limited at the positioning pin 8, the radial through hole of the sliding sleeve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com