Micro-domain photothermal composite material and preparation method thereof

A composite material, photothermal technology, applied in the fields of heating devices and micro-heating devices, can solve the problems of difficult to achieve local temperature control, increased complexity of microfluidic chips, interference of optical analysis of samples, etc., and achieve photothermal conversion efficiency. High, low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Surface modification of gold nanoparticles with mercapto polyethylene glycol molecules:

[0030] We used commercially available gold nanoparticles as raw materials (see www.nanoseedz.com), which were modified with cetyltrimethylammonium bromide (CTAB) as a surfactant and dispersed in water , we have a gold nanoparticle concentration of 1 x 10 in 10mL -10 -3×10 -10 mol / L aqueous solution (the concentration of surfactant CTAB is about 5×10 -4 mol / L) to add mercaptopolyethylene glycol molecules, so that the concentration of mercaptopolyethylene glycol molecules in the solution is 1 × 10 -4 mol / L, then let the solution stand Within hours, mercaptopolyethylene glycol molecules can be successfully coated on the surface of gold nanoparticles. At this time, the solution is centrifuged (centrifugal acceleration is about 9000g). After removing the supernatant, add 0.3mL of ethanol to the precipitate, and ultrasonically scattered;

[0031] 2. Embedding gold nanoparticles ...

Embodiment 2

[0036] One object of the application of the present invention is to provide a method for preparing a micro-domain photothermal composite material, which includes the following steps:

[0037] 1. Surface modification of gold nanoparticles:

[0038] At a gold nanoparticle concentration of 1 x 10 -10 ~3×10 -10 mol / L aqueous solution was added poly(sodium 4-styrenesulfonate) / PSS, which can coat gold nanoparticles, so that the concentration of polystyrene sodium sulfonate in the mixed solution was 0.8×10 -4 mol / L, let the solution stand for 6 hours, the polymer molecules can be successfully coated on the surface of gold nanoparticles, and then the solution is centrifuged at a centrifugal acceleration of 8500g. After removing the supernatant, add analytical pure gold to the precipitate ethanol, the volume of ethanol is less than or equal to 1 / 40 of the volume of the gold nanoparticle solution before centrifugation, and ultrasonic treatment is performed, the center frequency of the...

Embodiment 3

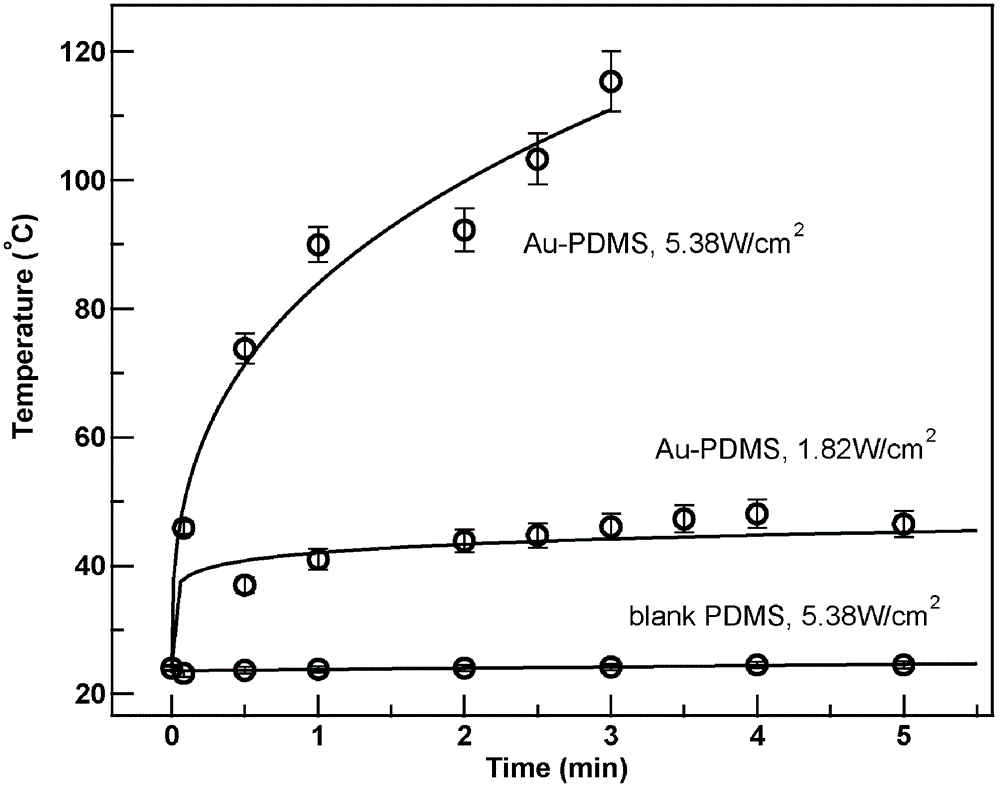

[0043] The heating curve of embodiment three laser heating

[0044] The heating curve of the laser-heated solution in the microfluidic cavity embedded with gold nanoparticles, different laser power densities (5.38 and 1.82W / cm 2 ), we also give the temperature rise curve in the blank microfluidic cavity (blank) as a reference, the microfluidic cavity is 100 microns wide, 150 microns deep, the heating laser is the laser of the semiconductor laser with a wavelength of 809nm, the temperature of the solution By measuring a concentration of 10 -4 The fluorescence intensity of mol / L rhodamine B solution excited by 543.5nm laser (power 267 microwatts) was indirectly measured.

[0045] It can be seen from the accompanying drawings that under the same laser power density, the slope of the temperature rise curve of the laser-heated solution in the microfluidic cavity embedded with gold nanoparticles is much larger than that in the blank microfluidic cavity (blank) The slope of , which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com