Straw-fiber-reinforced polyester tile and manufacturing method thereof

A straw fiber and manufacturing method technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of shortened service life, poor durability, and easy rust on the metal surface, so as to reduce production costs and The cost of use, the effect of enhancing the performance of sound insulation and heat insulation, and the effect of good wind and rain erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

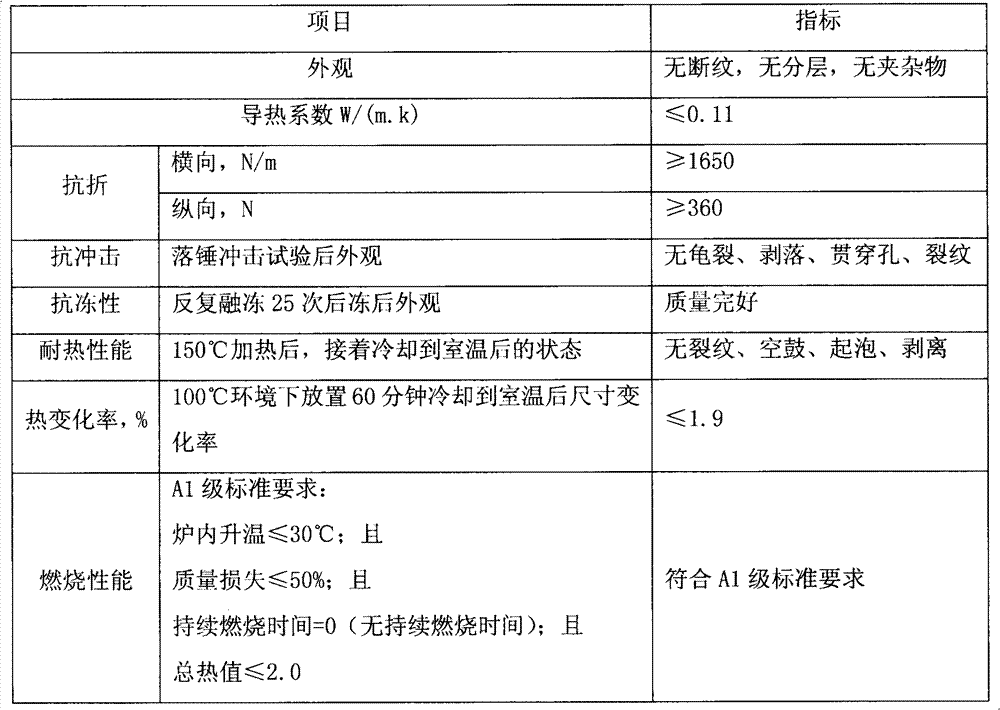

Image

Examples

Embodiment 1

[0042] (1) The straw is crushed into straw fibers with a size less than 3mm, dried and packed into bags for later use.

[0043] (2) Put 32kg of m-phenylene polyester resin, 8kg of styrene, 0.64kg of zinc stearate, 0.4kg of tert-butyl ester and 0.24kg of magnesium oxide into the stainless steel cylinder respectively, and use a speed-regulating disperser (model NH- 300) Stir at 600 rpm, 800 rpm, and 600 rpm for about 3 minutes each, mix well, remove from the cylinder, and discharge the air for later use.

[0044] (3) Put 9.6kg of mica powder, 41.92kg of acicular wollastonite powder, 12.8kg of talcum powder and 12.8kg of aluminum hydroxide powder into the kneader (model NH-300) trough and turn it on for about 3 minutes, mix well, shutdown.

[0045](4) Pour the resin slurry in the stainless steel cylinder after step (2) into the trough of the kneader and mix it with the functional filler, start stirring, and stir in the order of forward rotation, reverse rotation, and forward rot...

Embodiment 2

[0049] (1) The straw is crushed into straw fibers with a size less than 3mm, dried and packed into bags for later use.

[0050] (2) Put 100kg of isophthalic polyester resin and 1.5kg of oxalic acid into the reaction kettle (model FS--500), heat it to 110°C under the protection of nitrogen gas, stir for 3 hours, and drop to room temperature spare.

[0051] (3) 35.2kg of obtained oxalic acid modified m-phenylene polyester resin, 9.6kg of styrene, 0.8kg of zinc stearate, 0.48kg of tert-butyl ester and 0.32kg of magnesium oxide were dropped into respectively through step (2) In the stainless steel tank, use a speed-regulating disperser to stir at 600 rpm, 800 rpm, and 600 rpm for about 3 minutes, mix well, remove the tank, and discharge the air for later use.

[0052] (4) Put 12.8kg of mica powder, 24kg of acicular wollastonite powder, 16kg of talc powder and 16kg of aluminum hydroxide powder into the kneader (model NH-300) trough and turn it on for about 3 minutes, mix well and ...

Embodiment 3

[0057] (1) The straw is crushed into straw fibers with a size less than 3mm, dried and packed into bags for later use.

[0058] (2) Put 100kg of isophthalic polyester resin and 2.5kg of oxalic acid into the reaction kettle (model FS--500), heat it to 130°C under the protection of nitrogen gas, stir for 1.5 hours, and drop to room temperature spare.

[0059] (3) 38.4kg of obtained oxalic acid modified m-phenylene polyester resin, 11.2kg of styrene, 0.96kg of zinc stearate, 0.48kg of tert-butyl ester and 0.4kg of magnesium oxide are dropped into respectively through step (2) In the stainless steel tank, use a speed-regulating disperser to stir at 600 rpm, 800 rpm, and 600 rpm for about 3 minutes, mix well, remove the tank, and discharge the air for later use.

[0060] (4) Put 14.4kg of mica powder, 14.16kg of acicular wollastonite powder, 16kg of talc powder and 16kg of aluminum hydroxide powder into the kneader (model NH-300) trough and turn it on for about 3 minutes, mix well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com