Microwave heating device and application thereof

A microwave heating device, microwave device technology, applied in the chemical/physical/physicochemical process of applying energy, refining to remove heteroatoms, etc., can solve the industrial production of microwave heating devices that are difficult to scale and cannot be used to realize chemical reactions Process, no clear instructions and other issues, to achieve good operational safety, uniform distribution of microwave field, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

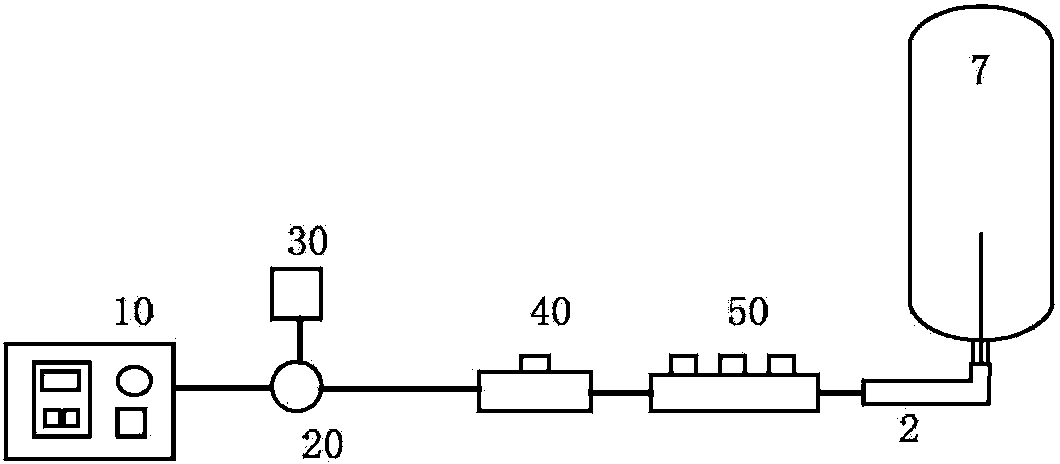

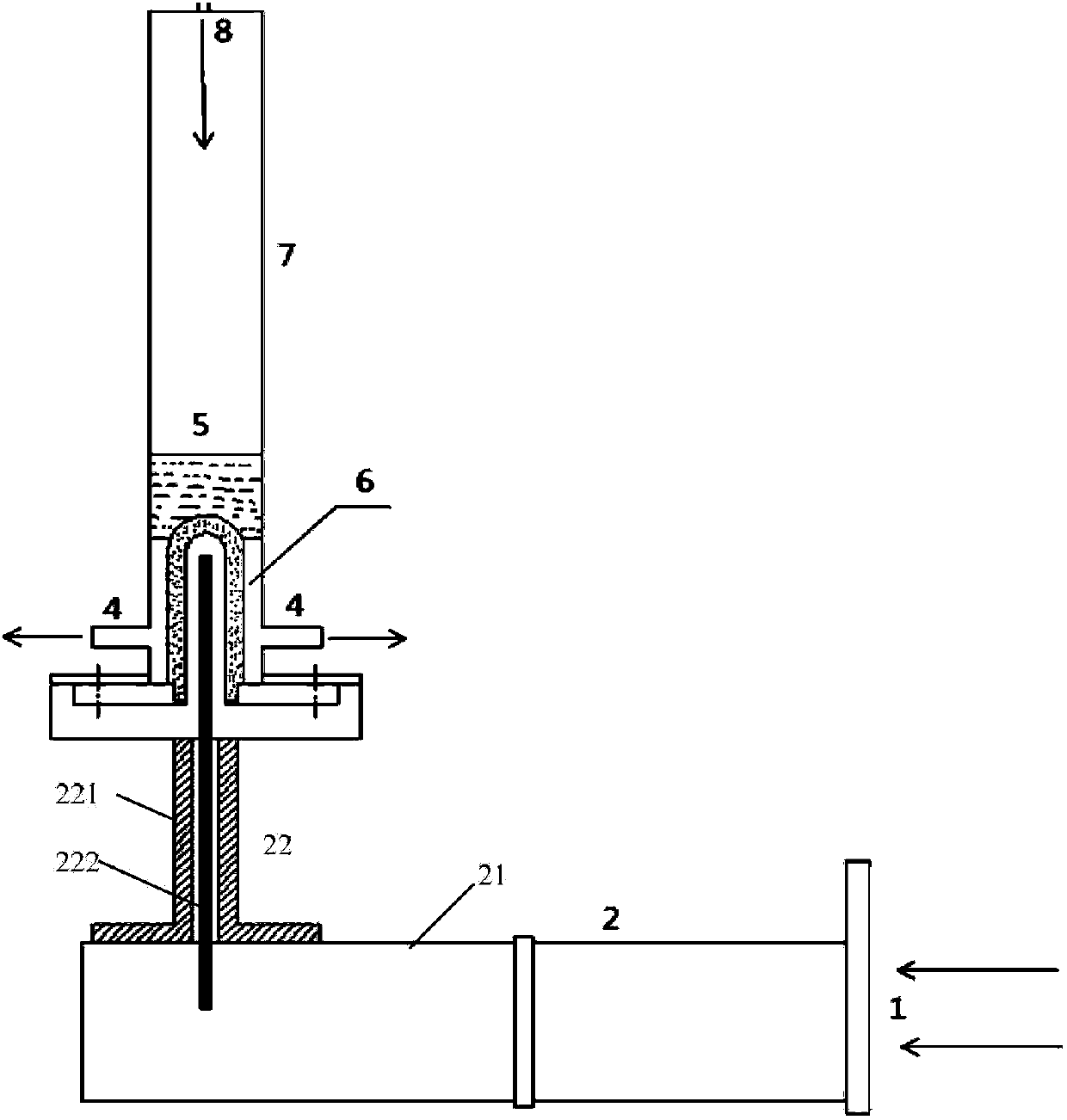

[0042] See figure 1 As shown, the microwave heating device of this embodiment includes a microwave source 10, a circulator 20, a water load 30, a directional coupler 40, a three-pin automatic regulator 50, a waveguide 2, and a microwave reactor 7 in the order of microwave conduction. see you again figure 2 The detailed structure of the shown waveguide section (according to those known in the art, microwave source, circulator, water load, directional coupler, and three-pin automatic adjuster are also directly connected by waveguide, and only shown in the figure as this A key feature of the invention is the structure of the waveguide section after the three-pin auto-adjuster according to the waveguide transmission sequence), wherein the waveguide 2 includes a rectangular waveguide 21 (the rectangular waveguide can also be a circular waveguide) and a coaxial waveguide 22, and The axial waveguide includes a coaxially arranged metal shell 221 (cylindrical) and a probe 222 (slende...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com