Desalination method of salted egg white

A salted egg white and desalination technology, applied in general water supply conservation, food preparation, food science and other directions, can solve problems such as unreported, and achieve the effect of effective industrial scaled production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

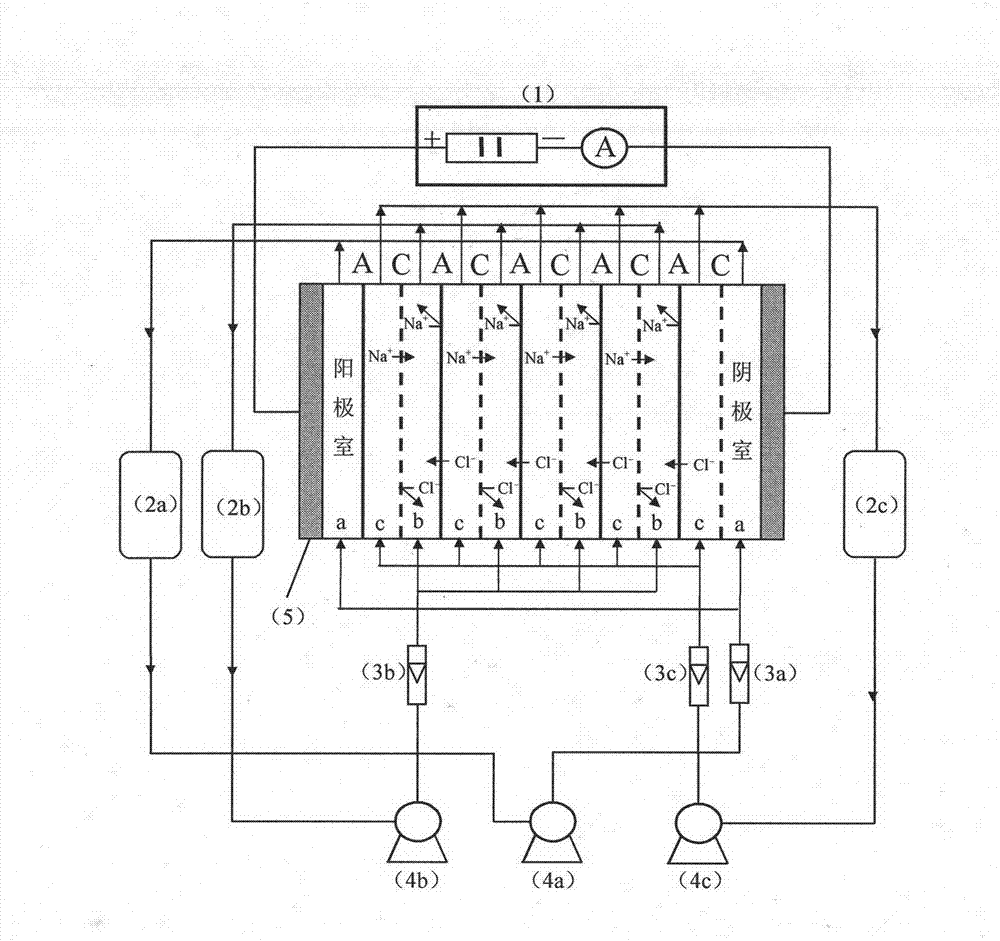

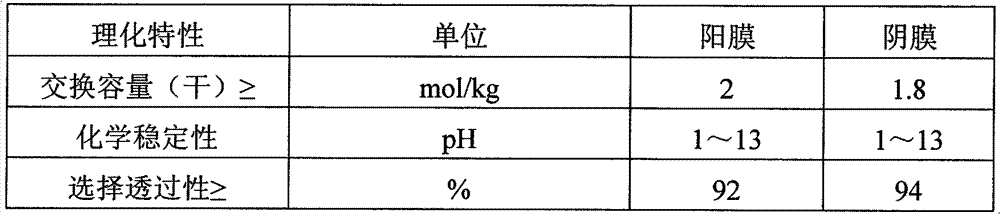

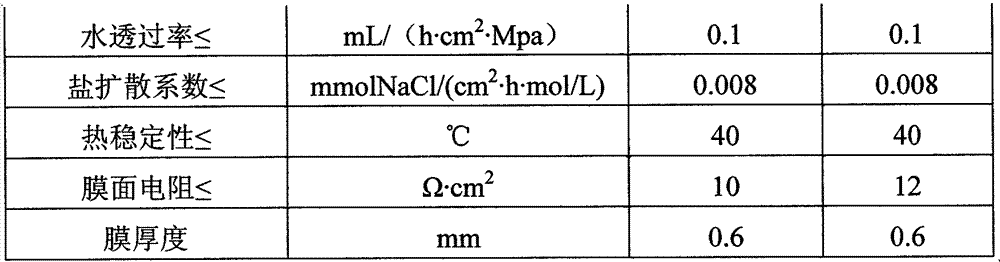

Method used

Image

Examples

Embodiment 1

[0038] Example 1: The influence of membrane voltage on the salt rejection rate of salted egg white

[0039] In this embodiment, through the test groups 1-5, the voltages are set to 10V, 20V, 30V, 40V, and 50V respectively, so that the film pair voltages are respectively 0.25V, 0.50V, 0.75V, 1.00V, 1.25V, and keep The other conditions are the same, to study the influence of membrane on voltage on salted egg white desalination rate.

[0040] Test group 1:

[0041] 1) After the salted egg white waste liquid used in this experiment is allowed to stand for 1 hour in a low temperature environment of 4°C, it is filtered twice with 3 layers of gauze to remove the residual egg yolk and impurities on the surface of the salted egg white. The conductivity of the salted egg white is about 6500μS / cm , The pH is about 6.8;

[0042] 2) Dilute the salted egg white obtained in step 1) with tap water 10 times its volume, and measure its conductivity to be 1468μS / cm, then adjust the pH to 7 with sodium ...

Embodiment 2

[0054] Example 2: The influence of the flow rate of the thick chamber and the flow rate of the weak chamber on the salted egg white desalination rate

[0055] In this embodiment, through test groups 6-10, the flow rates of tap water in the thick chamber tank 2b and the salted egg white in the weak chamber tank 2c are respectively set to 20L / h, 30L / h, 40L / h, 50L / h, 60L / h, keep other conditions consistent, and study the influence of thick and light room flow on salted egg white desalination rate.

[0056] In test group 6-10, the test procedure is the same as test 1. Except for changing the voltage in step 5) to 30V so that the membrane voltage is maintained at 0.75V; changing the flow rate of the salted egg white in the light chamber tank 2c and the tap water in the thick chamber tank 2b in step 4), and set the flow rates to 20L / h respectively , 30L / h, 40L / h, 50L / h, 60L / h, keep other parameters and conditions unchanged. After the electrodialyzer was operated for 160 minutes, the el...

Embodiment 3

[0062] Example 3: The effect of the initial conductivity of the salted egg white in the blight room on the salt rejection rate of the salted egg white

[0063] In this example, through the test group 11-14, the pretreated salted egg white was diluted 5 times, 10 times, 15 times, and 20 times its volume respectively, and then used as a shallow room liquid. Keeping other conditions consistent, the study The influence of the initial conductivity of the salted egg white in the room on the salt rejection rate of the salted egg white.

[0064] In experiment group 11-14, the experiment procedure is the same as experiment 1. In addition to changing the voltage in step 5) to adjust the voltage to 30V, so that the membrane voltage is maintained at 0.75V; in step 2), the salted egg white obtained in step 1) is diluted with tap water, and the volume is diluted 5 times and 10 times respectively. , 15 times, 20 times (measured conductivity is 3075μS / cm, 1472μS / cm, 1221μS / cm, 946μS / cm), keep oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com