Coffee yoghurt and preparation method thereof

A caffeic acid and coffee technology, applied in dairy products, milk preparations, applications, etc., can solve problems such as no coffee yogurt, adverse effects of processing, and normal fermentation of yogurt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1. Formula (see Table 1):

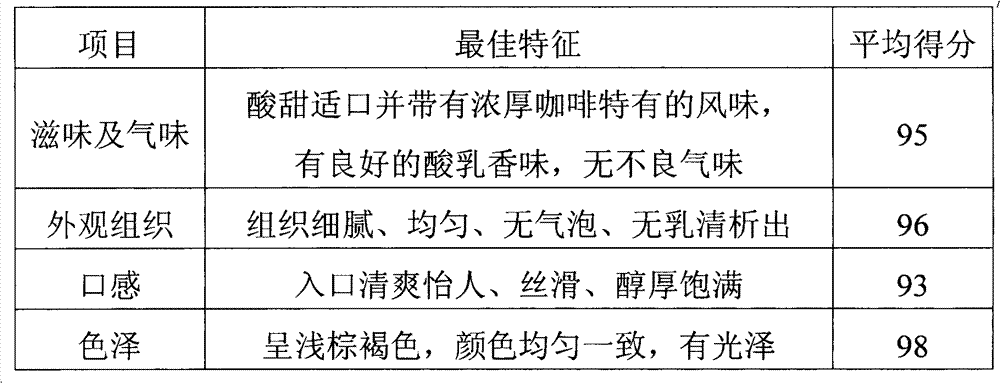

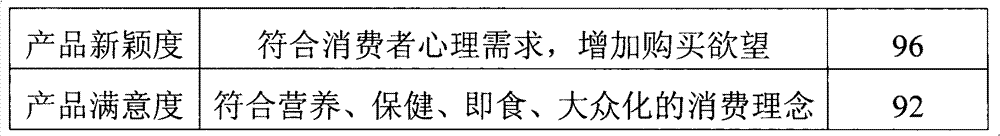

[0061] Table 1. Raw materials and addition amount (calculated on the basis of 1 ton of product)

[0062] raw material

Amount added (Kg)

697.151

coffee extract

100

White sugar

100

Hydroxypropyl Distarch Phosphate

18

2

Glyceryl monostearate fatty acid ester

5

sodium caseinate

5

whey protein powder

29

50

Vitamin A

0.009

Vitamin C

0.24

0.5

1.0

Yogurt Flavor

1.0

Streptococcus thermophilus

0.05

Lactobacillus bulgaricus

0.05

[0063] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0064] 2. Preparation process:

[0065] a) Preheat coffee extract, white sugar, hydroxypropyl distarch phosphate, pectin, glycer...

Embodiment 2

[0072] 1. Formula (see Table 2):

[0073] Table 2. Raw materials and addition amount (calculated on the basis of 1 ton of product)

[0074] raw material

Amount added (Kg)

975.099

coffee powder

0.5

Acesulfame K

0.15

0.15

1

2

[0075] Diacetyl tartrate monoglyceride

0.5

Propylene glycol fatty acid ester

0.5

whey protein powder

5

15

0.00028

0.1

Streptococcus thermophilus

0.0005

Lactobacillus casei

0.0005

[0076] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0077] 2. Preparation process:

[0078] a) Mix coffee powder, acesulfame potassium, aspartame, carrageenan, gelatin, monoglyceride diacetyl tartrate, propylene glycol fatty acid ester,...

Embodiment 3

[0085] 1. Formula (see Table 3)

[0086] Table 3. Raw materials and addition amount (calculated on the basis of 1 ton of product)

[0087] raw material

Amount added (Kg)

807.144

coffee extract

50

fructose syrup

60

0.5

Propylene glycol alginate

4

Acetylated Distarch Phosphate

10

2

whey protein powder

15

30

gamma-linolenic acid

20

0.8

0.5

Lactobacillus bulgaricus

0.005

Streptococcus thermophilus

0.05

0.001

[0088] Note: The performance indicators of each raw material meet the requirements of relevant quality standards.

[0089] 2. Preparation process:

[0090] a) Combine coffee extract, fructose syrup, sucralose, propylene glycol alginate, acetyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com