ZnO/graphene compound nano structure photo-anode for dye-sensitized solar cell and manufacture method of ZnO/graphene compound nano structure photo-anode

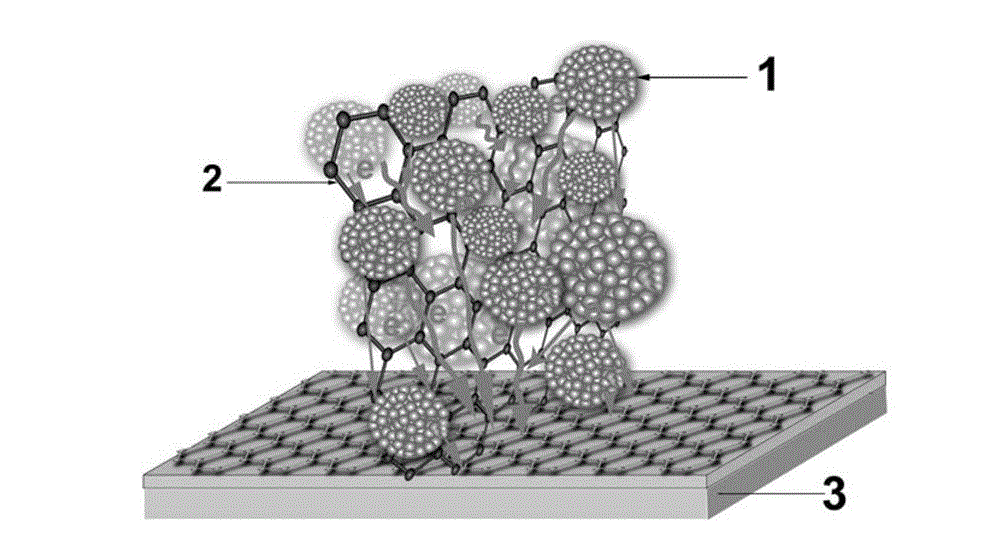

A graphene composite, solar cell technology, applied in circuits, capacitors, photovoltaic power generation and other directions, can solve the problems of graphene not being introduced and complicated, and achieve the effect of reducing electronic composite loss, low cost, and improving short-circuit current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

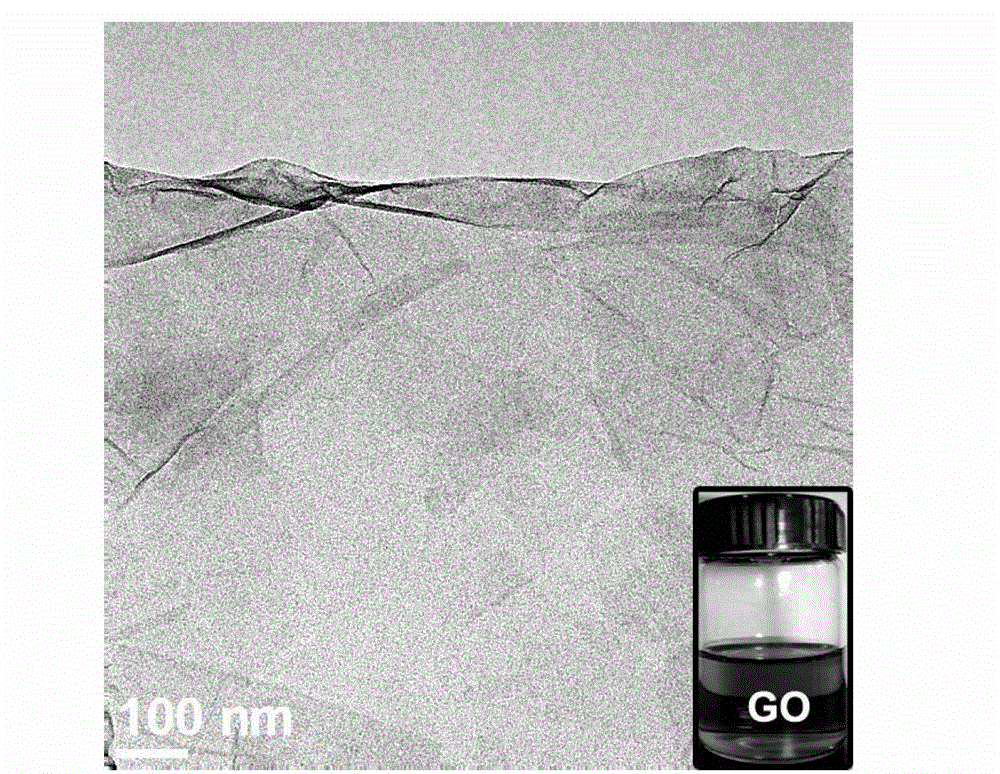

[0030] (1) Graphite oxide was prepared by the Hummers method, washed with deionized water and centrifuged at a speed of 10000~20000r / min, after repeated washing and centrifuged to obtain pure graphite oxide, which was ultrasonically dispersed in deionized water A graphene oxide solution with a concentration of 1 mg / mL was obtained.

[0031] (2) ZnAc 2 2H 2 O is dissolved in ethylene glycol, prepared into a solution with a concentration of 0.05~0.5 mol / L, heated to 150~200°C, condensed and refluxed for 4~24 hours for solvothermal reaction, and then the product is centrifuged and washed repeatedly with ethanol. Finally, it is dried to become a white ZnO nanoparticle powder.

[0032] (3) Dissolve polyvinyl alcohol in hot water at 70~100°C, and then further dilute it with ethanol aqueous solution prepared at a volume ratio of 1:1 to prepare a viscous liquid with a mass content of 5% polyvinyl alcohol.

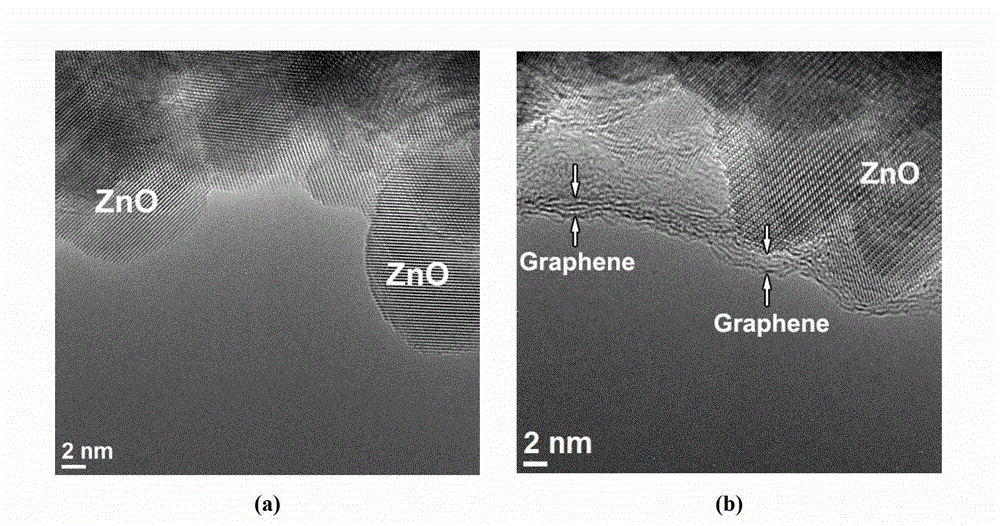

[0033] (4) Add ZnO nanoparticle white powder and graphene oxide solution to...

Embodiment 2

[0037] (1) Graphite oxide was prepared by the Hummers method, washed with deionized water and centrifuged at a speed of 10000~20000r / min, after repeated washing and centrifuged to obtain pure graphite oxide, which was dispersed in ethanol by ultrasonic to obtain The concentration is 3 mg / mL graphene oxide solution.

[0038] (2) ZnAc 2 2H 2O is dissolved in ethylene glycol, prepared into a solution with a concentration of 0.05~0.5 mol / L, heated to 150~200°C, condensed and refluxed for 4~24 hours for solvothermal reaction, and then the product is centrifuged and washed repeatedly with ethanol. Finally, it is dried to become a white ZnO nanoparticle powder.

[0039] (3) Dissolve polyvinyl alcohol in hot water at 70~100°C, and then further dilute it with ethanol aqueous solution prepared at a volume ratio of 1:1 to prepare a viscous liquid with a mass content of 10% polyvinyl alcohol.

[0040] (4) Add ZnO nanoparticle white powder and graphene oxide solution to the viscous liqu...

Embodiment 3

[0044] (1) Graphite oxide was prepared by the Hummers method, washed with deionized water and centrifuged at a speed of 10000~20000r / min, after repeated washing and centrifuged to obtain pure graphite oxide, which was ultrasonically dispersed in deionized water A graphene oxide solution with a concentration of 5 mg / mL was obtained.

[0045] (2) ZnAc 2 2H 2 O is dissolved in ethylene glycol, prepared into a solution with a concentration of 0.05~0.5 mol / L, heated to 150~200°C, condensed and refluxed for 4~24 hours for solvothermal reaction, and then the product is centrifuged and washed repeatedly with ethanol. Finally, it is dried to become a white ZnO nanoparticle powder.

[0046] (3) Dissolve polyvinyl alcohol in hot water at 70~100°C, and then further dilute it with ethanol aqueous solution prepared at a volume ratio of 1:1 to prepare a viscous liquid with a mass content of 10% polyvinyl alcohol.

[0047] (4) Add ZnO nanoparticle white powder and graphene oxide solution t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com