A kind of h-3 silicon carbide isotope battery and its manufacturing method

An isotope battery, H-3 technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of shallow electron range, recombination loss of radiation-induced carriers, and difficulty in radiation-induced carrier loss. Avoid other problems, achieve wide depletion region thickness, improve energy conversion efficiency and packaging density, and have high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

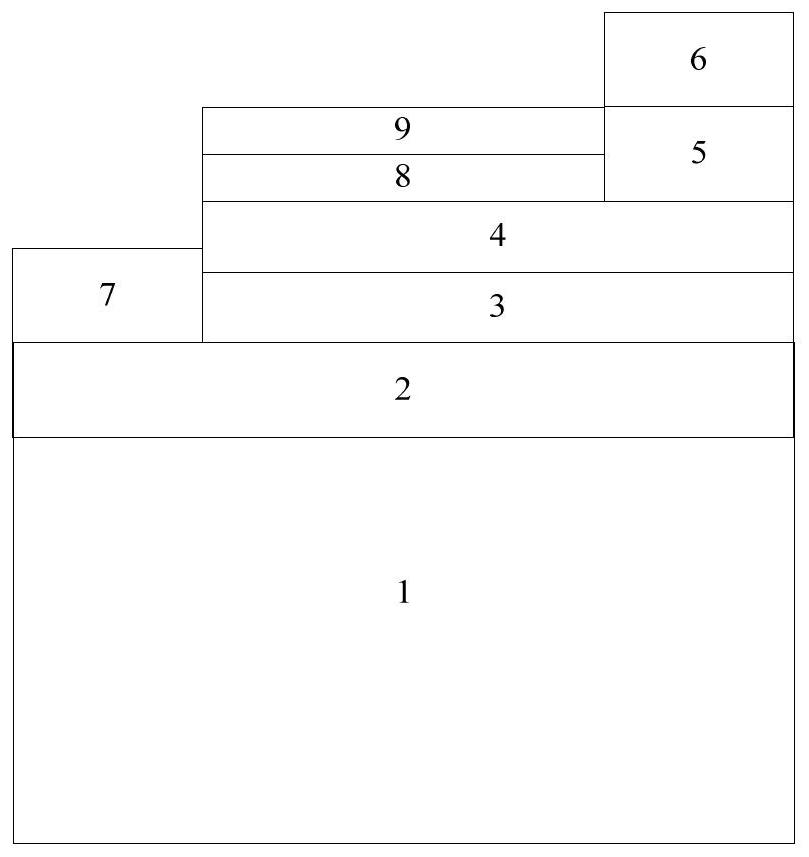

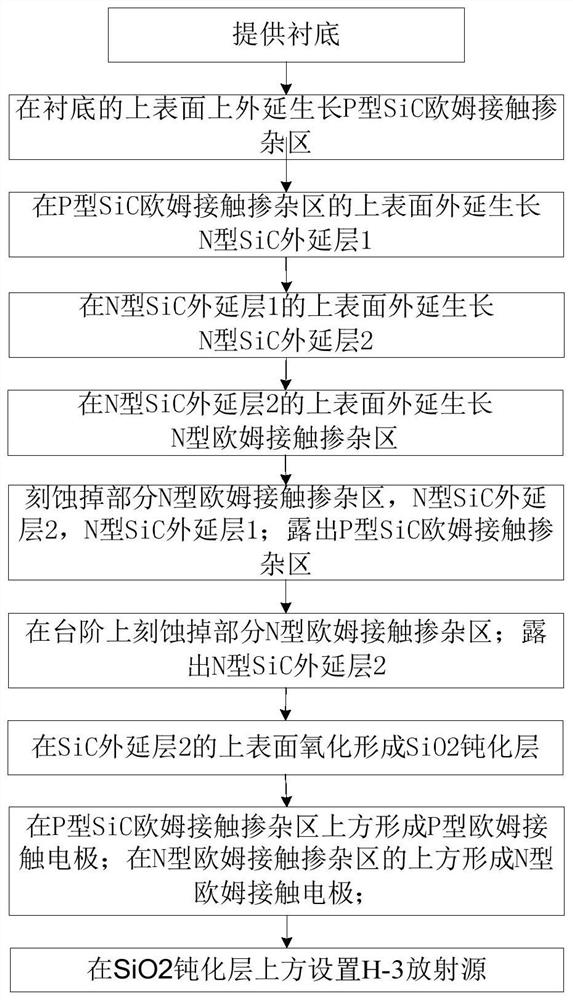

[0060] A kind of H-3 silicon carbide PN type isotope cell, comprises the following steps:

[0061] Step 1: providing an N-type doped SiC substrate (1);

[0062] Step 2: Using chemical vapor deposition to epitaxially grow on the upper surface of the substrate in Step 1 with a doping concentration of 1×10 19 cm -3 , a P-type SiC ohmic contact doped region (2) with a thickness of 1.0 μm;

[0063] Step 3: Using chemical vapor deposition to epitaxially grow the upper surface of the P-type SiC ohmic contact doped region (2) with a doping concentration of 4×10 17 cm -3 a first N-type SiC epitaxial layer (3) with a thickness of 1.0 μm;

[0064] Step 4: Using chemical vapor deposition to epitaxially grow the upper surface of the first N-type SiC epitaxial layer (3) with a doping concentration of 3×10 16 cm -3 , a second N-type SiC epitaxial layer (4) with a thickness of 0.5 μm;

[0065] Step 5: Using chemical vapor deposition to epitaxially grow the upper surface of the second N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com