Color filter and preparation method thereof, as well as liquid crystal display device

A technology of color filter and color filter layer, which is applied in the direction of filter, optics, nonlinear optics, etc., can solve the problems of limited supply, low electrical conductivity, poor wear resistance, etc., and achieve cost saving and material reduction The effect of cost reduction and process cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the color filter of this structure comprises the following steps:

[0051] 1) Firstly, a black matrix layer is formed on one side of the substrate, and a spacer is formed on the black matrix layer;

[0052] 2) Then forming a color filter layer located in the opening area of the black matrix layer on the other side of the substrate;

[0053] 3) Finally, a layered bishydroxy hydroxide stripping liquid is coated on the color filter layer, and a planarized conductive layer is formed after removing the solvent.

[0054] Another structure is: the spacer is arranged on one side of the substrate, the black matrix layer, the color filter layer (including but not limited to R, G, B filter layers), the planarization The conductive layer is arranged on the other side of the substrate, and the color filter layer is located in the opening area of the black matrix layer.

[0055] The preparation method of the color filter of this structure comprises the...

Embodiment 1

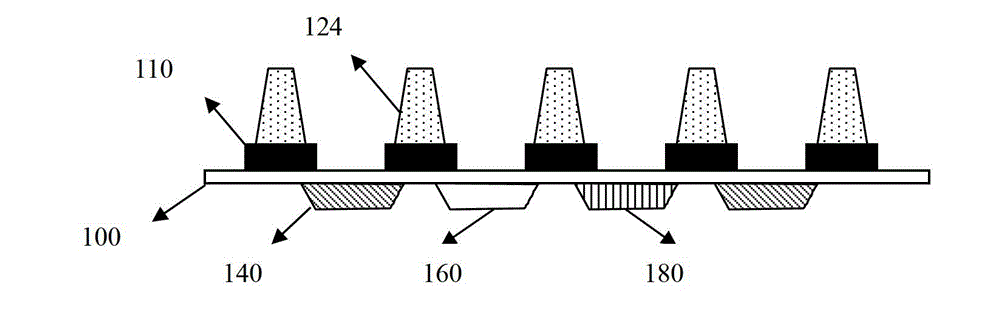

[0079] The color filter of the present embodiment comprises a substrate 100, a black matrix layer 110 and a spacer 124 are arranged on one side of the substrate 100, and the color filter layers (red filter layer 140, green filter layer 160 and blue filter layer 180), the planarized conductive layer 170 is arranged on the other side of the substrate 100, the color filter layer (140, 160 and 180) is located in the opening area of the black matrix layer 110, and the planarized conductive layer 170 is peeled off by layered double hydroxy hydroxide liquid formed.

[0080] Its preparation process is as Figures 1A-1D and Figure 4 As shown, the specific process is:

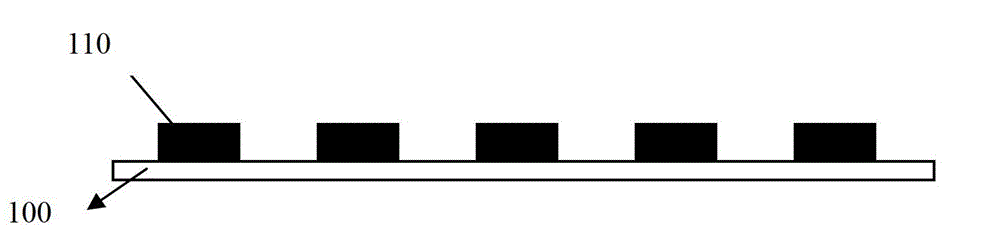

[0081] 1. First, prepare a black matrix layer 110 on the front of the substrate 100 by exposure and development, and prepare spacers 124 on the black matrix layer 110 by exposure and development;

[0082] 2. The substrate 100 is turned upside down, and the color filter layers (140, 160 and 180) are respectively pre...

Embodiment 2

[0093] The basic structure of the color filter of this embodiment is the same as that of Embodiment 1, the difference is that the preparation process of the layered double hydroxy hydroxide stripping solution is:

[0094] 1) Mix cobalt nitrate aqueous solution and aluminum nitrate aqueous solution to form a mixed salt solution, and then react with sodium hydroxide aqueous solution, the concentration of cobalt nitrate solution is 0.5mol / L, the concentration of aluminum nitrate solution is 0.2mol / L, sodium hydroxide The concentration of the solution is 1.0mol / L, the reaction temperature is controlled at 80°C, nitrogen protection is introduced, the reaction is continued for 18 hours, centrifuged at 3500rpm / min, and dried at 40°C in vacuum to obtain a powdery product;

[0095] 2) Take 40g of the powder product, add it to 1L deionized water (the mass ratio of the two is 1:25), continue strong mechanical stirring for 18 hours, and centrifuge at 3500rpm / min to obtain a transparent and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com