Detection kit for calcium peroxide in flour and detection method for calcium peroxide

A calcium peroxide and kit technology, which is applied in the direction of material analysis by observing the influence on chemical indicators, and analysis by chemical reaction of the material, can solve the problem of not detecting the calcium peroxide kit in flour, etc., Achieve the effect of strong practicability, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

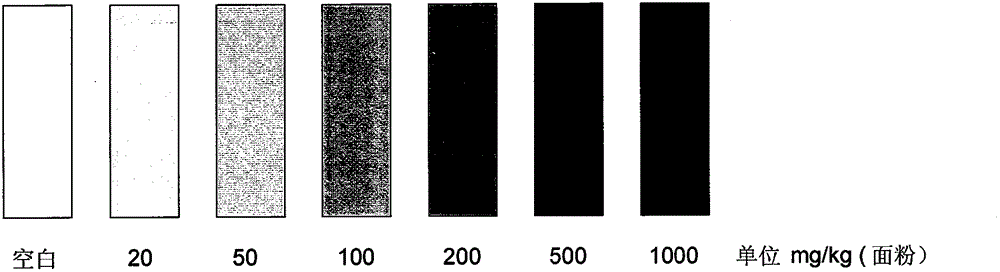

[0036] Preparation of standard color chart

[0037] Analysis steps: Accurately weigh 10g of wheat flour sample without calcium peroxide whitening agent (accurate to 0.01g) in a 100mL colorimetric tube, then weigh high-purity reagent calcium peroxide 0mg, 0.20mg, 0.50mg respectively , 1.00mg, 2.00mg, 5.00mg, and 10.00mg were added to the colorimetric tube, and 50mL of 1% dilute sulfuric acid was added sequentially, vortexed, and reacted at room temperature for 10min. With 20% and 0.1% sodium hydroxide solution Adjust the pH value to 7.0, add 3mL of enzyme reagent solution, dilute to 100mL with secondary water, keep the temperature in a 37°C water bath with a horizontal shaker for 10min, and cool to room temperature to obtain a series of blank matrix standard solutions, corresponding to each A kilogram of flour contains 0 mg, 20 mg, 50 mg, 100 mg, 200 mg, 500 mg, and 1000 mg of calcium peroxide. The colored solution is photographed, and the color collected is made into a standar...

Embodiment 2

[0039] Calcium Peroxide Rapid Determination Kit

[0040] The kit is equipped with: plastic sample spoons, 2 pieces, filled with a flat spoon of flour with a mass of about 2g; 3mL disposable plastic droppers with scales, 100 pieces; 50mL stoppered glass colorimetric tubes, 30 pieces; 50mL plastic measuring cylinders, 1 piece; test tube rack, 1 piece, 20 holes, the diameter of the hole is suitable for 50mL stoppered glass colorimetric tube; standard color comparison card, 1 piece, which contains blank and 6 series of colors in gradient changes from light red to deep red The content of calcium peroxide represented by each strip is marked below each strip; broad pH test paper (1-14), 2 boxes; precision pH test paper (6.4-8.0), 2 boxes; reaction reagents: three kinds of reagents in plastic bottles, respectively Labeled as 1% dilute sulfuric acid, 20% dilute sodium hydroxide, 0.1% sodium hydroxide, 500mL per bottle. 500mL plastic washing bottle, filled with distilled water, 1pc.

Embodiment 3

[0042] Analysis steps: Take a scoop of dumpling powder of a certain brand in a 50mL colorimetric tube, add 20mL of 1% dilute sulfuric acid, react at room temperature for 10min, after cooling to room temperature, adjust the pH value to 7.0 with 20% and 0.1% sodium hydroxide solution , add 2mL of enzyme reagent solution, dilute to the mark with secondary water, and shake well. After developing the color for 5 minutes at room temperature, observe the color. The sample is a pink cloudy solution, indicating that the sample contains calcium peroxide. Compared with the standard color card, the color of the test solution is close to the color of the standard color bar of 100mg / kg, indicating that calcium peroxide has been detected in the sample, and the content is about 100mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com