Incomplete gearbox cutting reversing device

A technology of reversing device and gear box, which is applied in the direction of gear transmission device, cutting machinery, transmission device, etc. It can solve the problems that cannot meet the requirements of the pick test, and achieve the effect of reliable mechanical realization of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

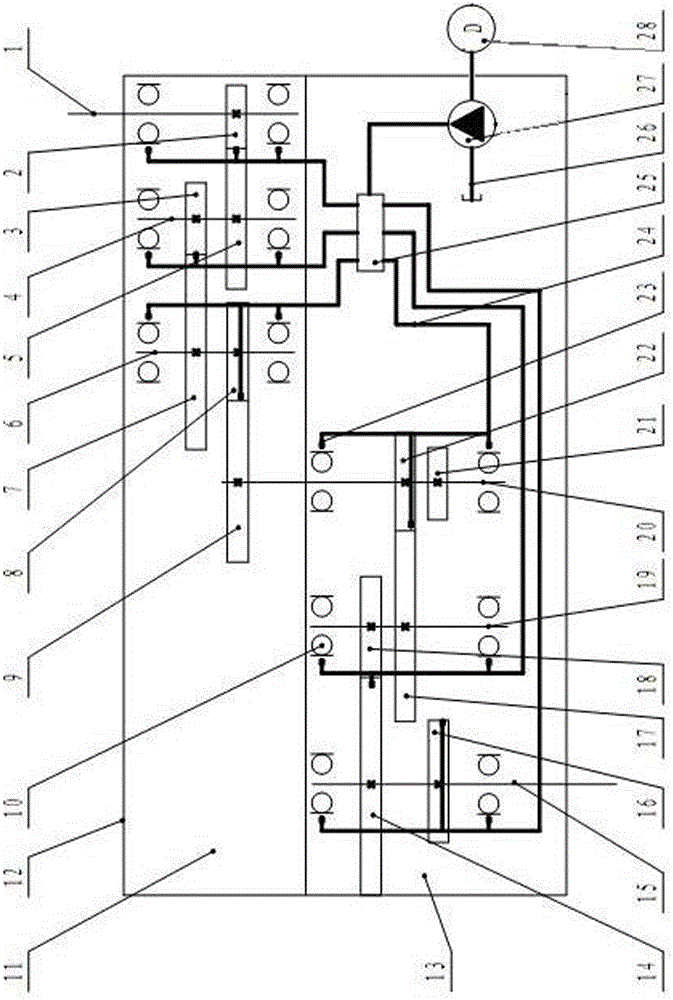

[0011] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0012] The first gear 2 is mounted on the input shaft 1, the first gear 2 meshes with the second gear 5, the second gear 5 and the third gear 3 are double-mounted on the first shaft 4, the third gear 3 and the fourth gear 7 meshing, the fourth gear 7 and the fifth gear 8 are installed on the second shaft 6, the fifth gear 8 and the sixth gear 9 mesh, the sixth gear 9, the seventh gear 22 and the twelfth gear 21 are installed in three On the shaft 20, the seventh gear 22 meshes with the eighth gear 17, the eighth gear 17 and the ninth gear 18 are installed on the fourth shaft 19; the ninth gear 18 meshes with the tenth gear 14, and the tenth gear 14 and the eleven Number gear 16 is contained on the output shaft 15.

[0013] The input shaft 1, the first shaft 4, and the second shaft 6 are all located in the deceleration chamber 11, and the third sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com