Spinning spindle assembly

A component and spindle technology, which is applied in the field of the driving mechanism of the spindle of the spinning frame, can solve the problems of high linear speed noise of the spindle belt, harsh production environment, unfavorable high-speed operation of the spindle, etc., so as to increase the limit speed, prolong the life of the spindle, and improve the working environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

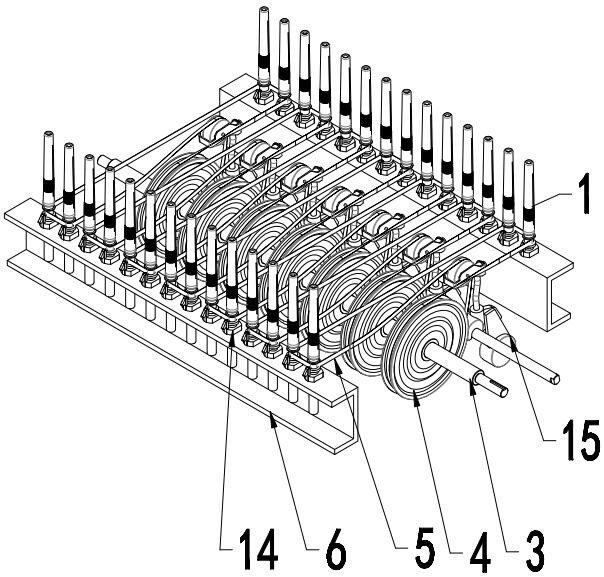

[0036] The outer surface of the drive disk casing 812 is provided with a transmission part. In this embodiment, the transmission part is a concave ring 8121 that can be embedded in the transmission belt. The spindle belt of the driving mechanism can be embedded in this concave ring 8121 and cling to the outer wall of the drive disk casing 812 , the driving disk casing 812 is driven to rotate through the spindle tape, so that the driving disk 811 is rotated.

[0037] A bearing 84 is arranged in the inner cavity of the lower part of the drive disk casing 812 , and the bearing 84 is sleeved outside the fixed disk casing 832 .

[0038] Thrust bearing 841 is also arranged in the inner cavity of the bottom end of the drive disk casing 812, and the thrust bearing 841 is limited by a fixed cap 843 and threaded on the inner cavity of the fixed disk casing 832 with a bolt 842, so that the drive disk casing The 812 will not move axially on the fixed disk sleeve.

[0039] The fixed plate...

Embodiment 2

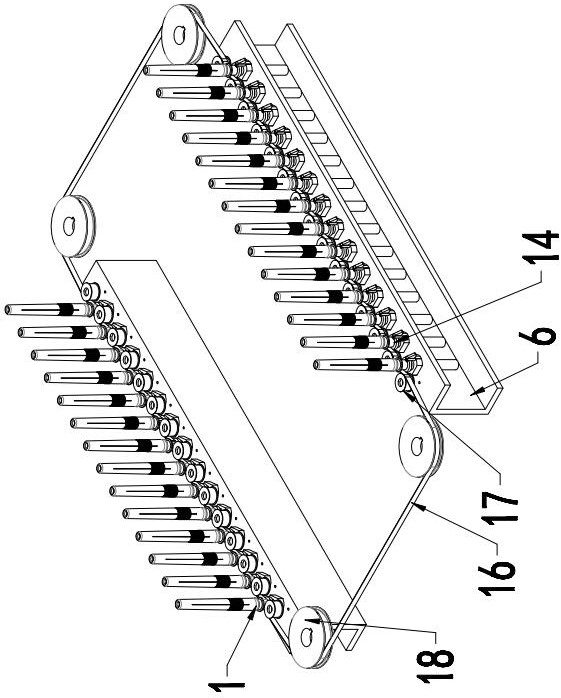

[0057] Except this embodiment and embodiment 1 fixed plate is fixed on the dragon tendon 6 or other textile mechanism, can also use other commonly used two object fixing ways to fix the fixed plate on the dragon tendon 6, no longer here List them all.

[0058] The structure of the drive disc assembly of this embodiment is identical to that of the drive disc of Embodiment 1 except that the number of drive magnetic grains uniformly distributed along the circumference of the drive disc and the screw thread on the outer circumference of the drive disc are the same. The drive disc of this embodiment is 77 Twelve driving magnetic particles 82 are evenly distributed along its circumference.

[0059] Four driven magnetic particles 89 are installed on the driven disk of the spindle assembly of this embodiment, and the rest are identical to Embodiment 1. The lower part of the spindle rod is inserted into the bearing, and the spindle rod can rotate coaxially around the fixed disk.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com