Strong uniformly-stitched and bonded nonwoven fabric, production method and production device

A non-woven fabric, strong technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as affecting product quality and brand reputation, high consumption of raw materials, uneven longitudinal and lateral breaking strength of stitched non-woven fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

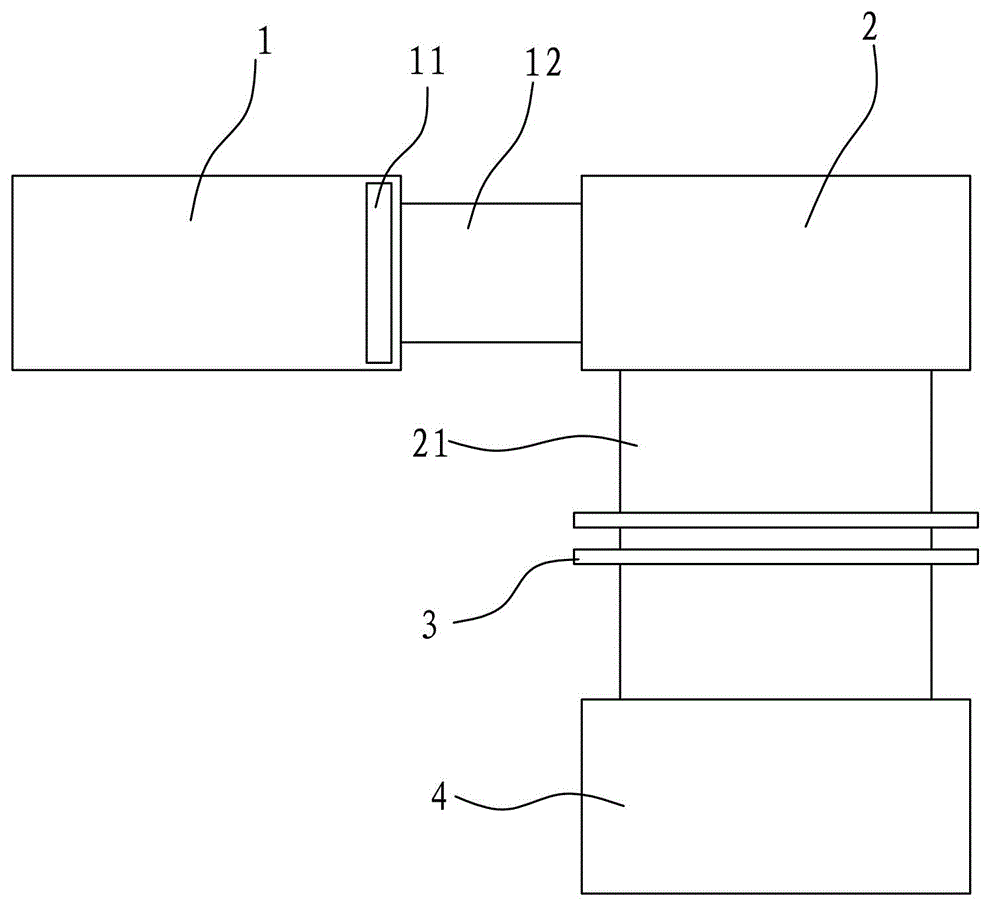

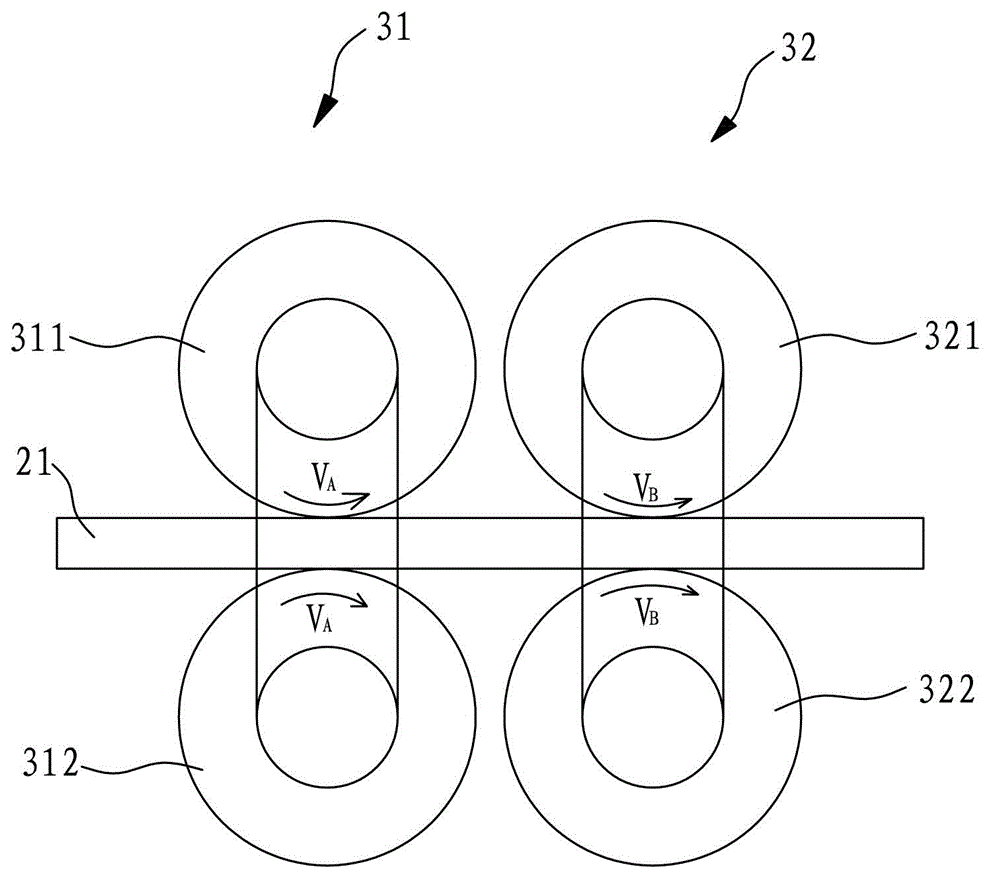

Method used

Image

Examples

Embodiment 1

[0036] Stitch-bonded nonwovens 90gsm with a pitch of 1.6mm; if produced by traditional methods, the longitudinal breaking strength is 267N / 5CM, and the transverse breaking strength is 56N / 5CM; that is, the ratio of longitudinal breaking strength to transverse breaking strength is 4.7:1.

[0037] And using the production method of the present invention, the longitudinal breaking strength of the stitch-bonded nonwoven fabric obtained by it is 205N / 5CM, and the transverse breaking strength is 185N / 5CM, that is, the ratio of the longitudinal breaking strength and the transverse breaking strength is 1.1:1.

[0038] It can be seen that the transverse fracture strength is greatly improved, and the longitudinal and transverse fracture strength ratio is in the range of 1-1.2.

Embodiment 2

[0040] Stitch-bonded non-woven fabric 130gsm needle distance 1.6mm product; if produced by traditional methods, the longitudinal breaking strength is 236N / 5CM, and the longitudinal breaking strength is 140N / 5CM; that is, the ratio of longitudinal breaking strength to transverse breaking strength is 1.6:1.

[0041] And using the production method of the present invention, the longitudinal breaking strength of the stitch-bonded nonwoven fabric obtained is 220N / 5CM, and the transverse breaking strength is 215N / 5CM, that is, the ratio of the longitudinal breaking strength to the transverse breaking strength is 1:1.

[0042] It can be seen that the transverse fracture strength is greatly improved, and the longitudinal and transverse fracture strength ratio is in the range of 1-1.2.

Embodiment 3

[0044] Stitch-bonded nonwoven fabric 160gsm needle distance 1.8mm product; if it is produced by traditional method, the longitudinal breaking strength is 318N / 5CM, and the longitudinal breaking strength is 108N / 5CM; that is, the ratio of longitudinal breaking strength to transverse breaking strength is 2.9:1.

[0045] And using the production method of the present invention, the longitudinal breaking strength of the stitch-bonded nonwoven fabric obtained by it is 298N / 5CM, and the transverse breaking strength is 275N / 5CM, that is, the ratio of the longitudinal breaking strength and the transverse breaking strength is=1.1:1.

[0046] It can be seen that the transverse fracture strength is greatly improved, and the longitudinal and transverse fracture strength ratio is in the range of 1-1.2.

[0047]In summary, in the fiber web formation process of the present invention, the fibers in the fiber web are arranged horizontally through physical force interference, and then stitched w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com