Method for preparing nickel sulfide concentrate through titanium dioxide waste acids

A technology of titanium white waste acid and nickel sulfide concentrate, which is applied in the direction of improving process efficiency, can solve the problems of a large number of equipment, difficulty in removing iron, and large investment, and achieve the effects of low production cost, reduced leaching, and reduced iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

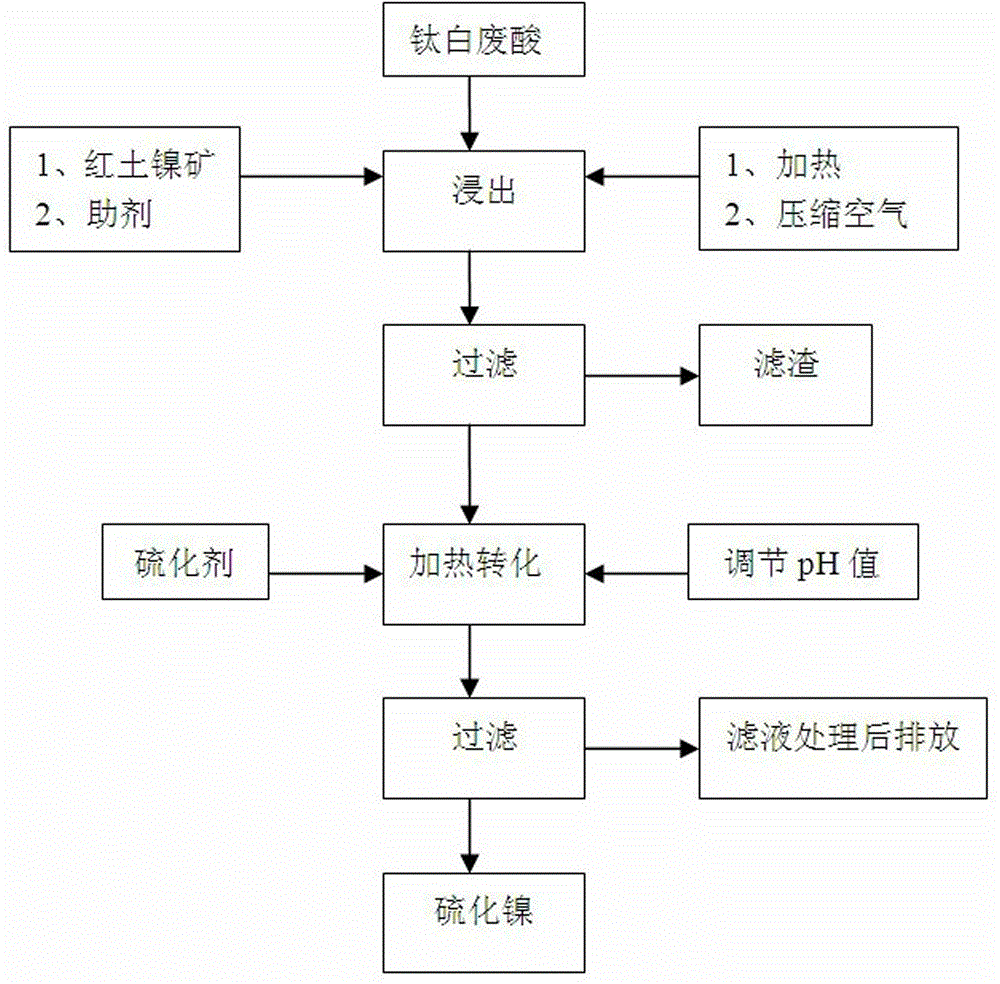

Image

Examples

Embodiment 1

[0020] Embodiment 1 (the content of all acid and nickel in the embodiment is weight content)

[0021] 1000Kg of laterite nickel, add 3500Kg of 22% titanium white waste acid, start stirring to make a slurry, raise the temperature to 80°C, stir and extract at normal pressure for 45 minutes, add 150Kg of sodium sulfate solid, add sodium hydroxide to adjust pH = 4.2, blow into Compress air, continue to react for 1.5 hours, cool down to 40°C and filter, put the filtrate into the reactor, heat to 80°C under stirring, add 280Kg powdered ferrous sulfide, keep warm for 3 hours, cool down to 50°C, filter, and the filter residue is It is a nickel sulfide concentrate with a nickel content of 11.5%.

Embodiment 2

[0023] 1000Kg of laterite nickel, add 5200Kg of 15% titanium white waste acid, start stirring to make a slurry, raise the temperature to 80°C, stir and extract at normal pressure for 60 minutes, add 100Kg of potassium chloride solid, add sodium hydroxide to adjust pH = 3.0, blow Add compressed air, continue to react for 2 hours, filter, put the filtrate into the reactor, heat to 90°C under stirring, add 300Kg powdered calcium sulfide, keep warm for 3 hours, cool down to 50°C, filter, and the filter residue is nickel sulfide concentrate , the nickel content is 8.3%.

Embodiment 3

[0025] 1000Kg of laterite nickel, add 5200Kg of 18% titanium white waste acid, turn on the stirring to make a slurry, raise the temperature to 80°C, stir and extract at normal pressure for 60 minutes, add 100kg of ammonium sulfate solid, add sodium hydroxide to adjust pH = 3.0, blow into Compress the air, continue to react for 2 hours, filter, put the filtrate into the reactor, heat to 90°C under stirring, add 300Kg powdered ammonium sulfide and ammonium disulfide, keep the temperature down to 50°C after 3 hours of heat preservation reaction, filter, and the filter residue is sulfide Nickel concentrate with a nickel content of 13.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com