Apparatus and method for coal powder cyclone entrained flow gasification

A gasification device and entrained bed technology, which is applied in the field of pulverized coal cyclone entrained bed gasification devices, can solve the problems of thermal damage to the furnace wall surface, short residence time, low carbon conversion rate, etc., so as to improve work safety and disperse heat. Load, the effect of improving carbon conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

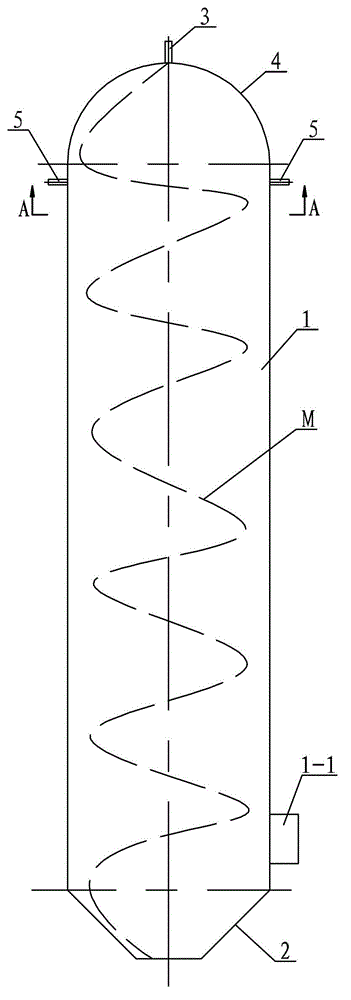

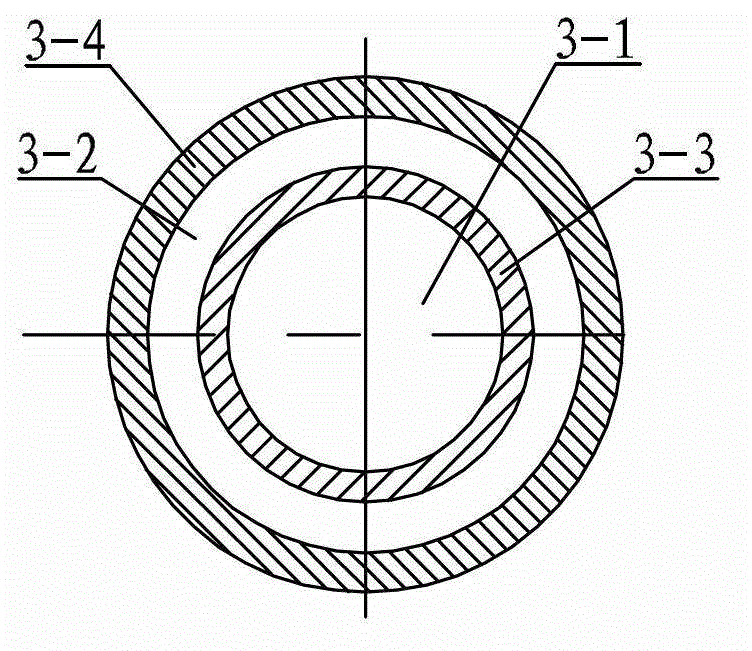

[0021] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, this embodiment comprises cylindrical gasification chamber 1, slag pool 2, top nozzle 3, furnace top 4 and four oxidant nozzles 5, furnace top 4 is arranged on the top of cylindrical gasification chamber 1, slag pool 2 is arranged at the bottom of the cylindrical gasification chamber 1, the lower side wall of the cylindrical gasification chamber 1 is provided with a crude synthesis gas outlet 1-1, the top nozzle 3 is arranged on the furnace roof 4, and the axis of the top nozzle 3 is in line with the cylinder The axis of the gasification chamber 1 coincides, the top nozzle 3 is composed of an inner cylinder 3-3 and an outer cylinder 3-4, the inner cylinder 3-4 is arranged in the outer cylinder 3-5, and the inner cavity of the inner cylinder 3-4 is pulverized coal The nozzle 3-1, the cavity between the inner cylinder 3-4 and the outer cylinder 3-4 is a steam nozzle 3-2, and four oxi...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, the four oxidant nozzles 5 of this embodiment are arranged at the same height, and the acute angle α between the axis of each oxidizer nozzle 5 and the diameter of the cylindrical vaporization chamber 1 is 25° to 50°. The jet extension lines of the oxidizer nozzle 5 are all tangent to the inscribed circle K. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

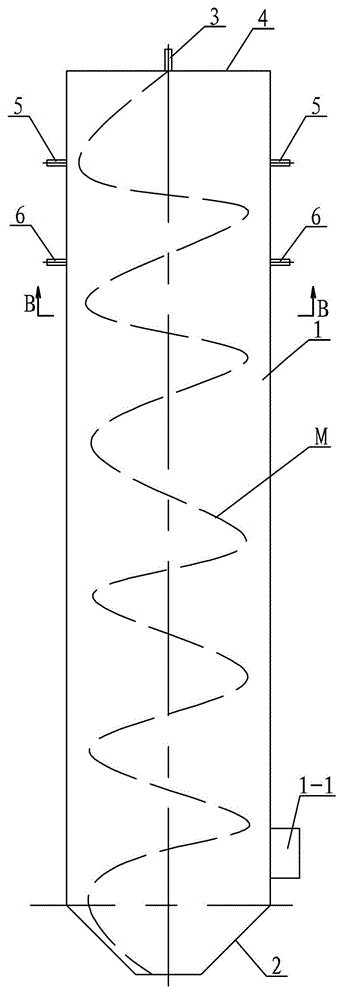

[0023] Specific implementation mode three: combination Figure 5 To illustrate this embodiment, the four oxidant nozzles 5 of this embodiment are arranged in two layers on the side wall of the cylindrical gasification chamber 1, two oxidant nozzles 5 are arranged on each layer, and the oxidant nozzle 5 on the upper layer is the upper layer oxidant nozzle 5- 1. The lower oxidant nozzle 5 is the lower oxidant nozzle 5-2, the two upper oxidant nozzles 5-1 are arranged at the same height, and the two upper oxidant nozzles 5-1 are arranged diagonally, and the two lower oxidant nozzles 5-2 They are arranged at the same height, and the two lower layer oxidant nozzles 5-2 are arranged diagonally, the acute angle α between the axis of each oxidant nozzle 5 and the diameter of the cylindrical gasification chamber 1 is 25°-50°, and the two upper layer The jet extension lines of the oxidizer nozzle 5-1 and the two lower layer oxidizer nozzles 5-2 are all tangent to the inscribed circle K....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com