Method for machining stereoscopic patterns of aluminum plate surface

A technology of three-dimensional patterns and processing methods, which is applied in decorative arts, embossed ornaments, etc., to achieve the effect of simple processing methods, guaranteed accuracy, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

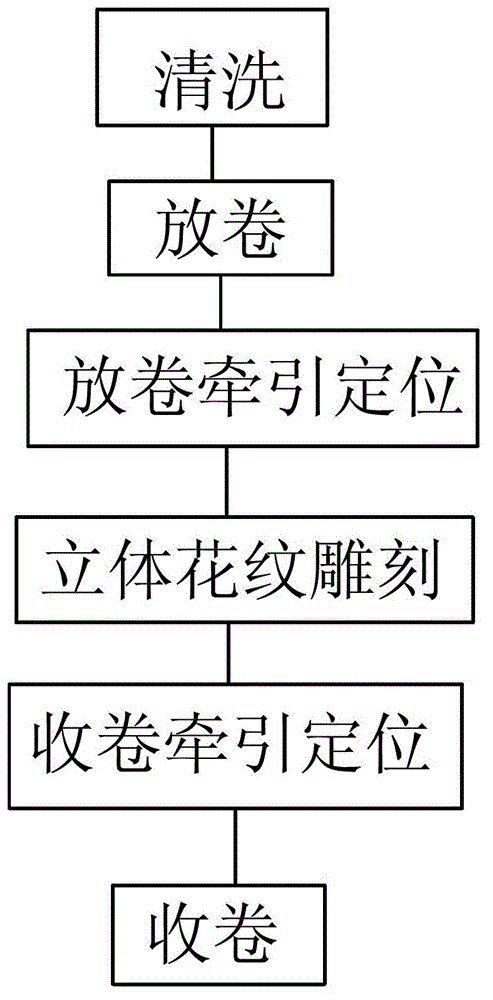

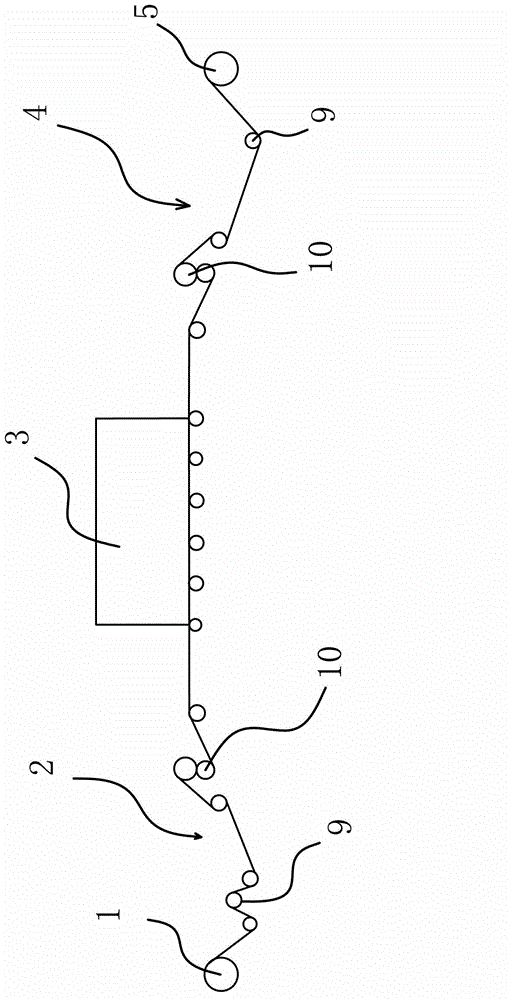

[0032] Such as figure 1 , figure 2 with image 3 As shown, the processing method of the three-dimensional pattern on the surface of the aluminum plate includes the following processes:

[0033] a. Cleaning: removing oil stains and impurities on the surface of the aluminum plate 11 by cleaning; the cleaning in step a includes sequentially passing the surface of the aluminum plate 11 through alkaline washing, acid washing and passivation treatments. Through the above-mentioned several steps of processing, basically all the oil stains and impurities on the surface of the aluminum plate 11 are removed.

[0034] b. Unwinding: Place the aluminum coil rolled into a cylindrical aluminum plate 11 on the unwinding mechanism 1. In this embodiment, the aluminum coil size is generally 0.12*1270mm, and the unwinding tension is determined according to the weight of the aluminum coil and the pattern type The preset value of is 70-80N, and the unwinding tension of the unwinding mechanism 1 is adj...

Embodiment 2

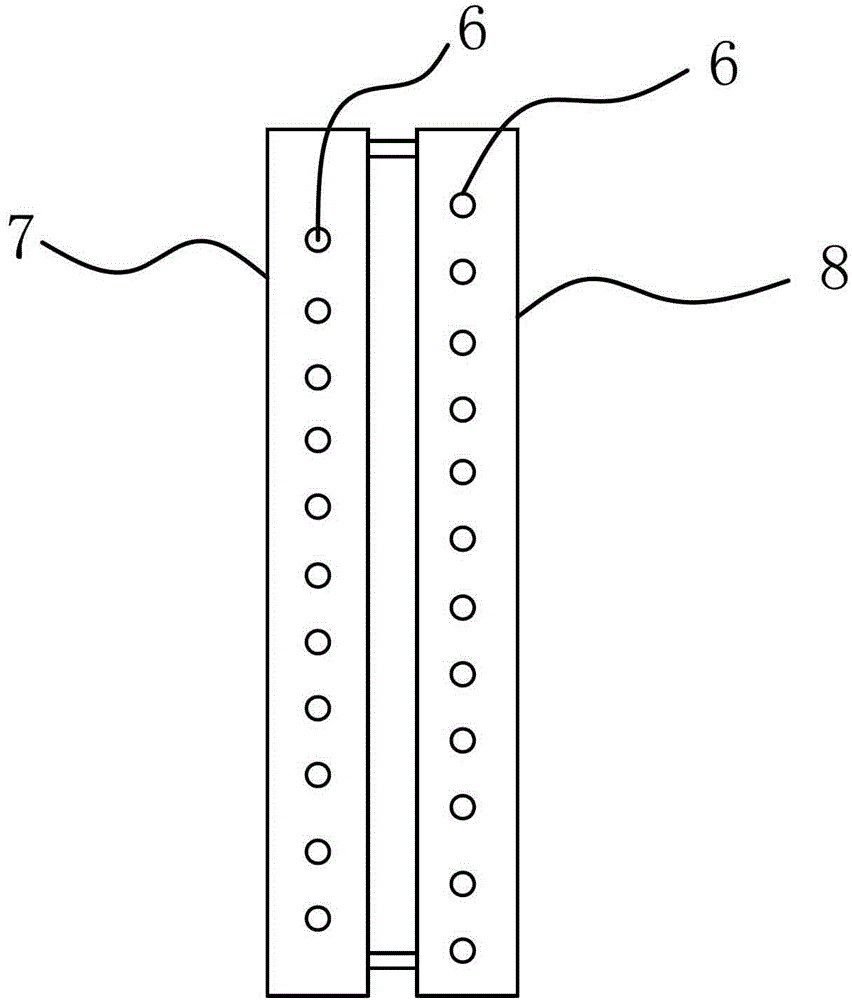

[0041] The general content of this embodiment is the same as that of the first embodiment. The difference is that in this embodiment, the numerical control grinder device 3 includes a plurality of grinding heads 6, and each grinding head 6 is connected with a servo motor for driving. The distribution mode of the grinding head 6 is disc distribution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com