Manufacturing method and device of plastic hook hook and loop fastener and plastic hook hook and loop fastener

A manufacturing method and technology of hook and loop fasteners, applied in fasteners, clothing, applications, etc., can solve problems such as insufficient cooling effect, material distortion, and reduced production efficiency, and achieve beautiful and durable appearance, reduced wear, and neatly arranged Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

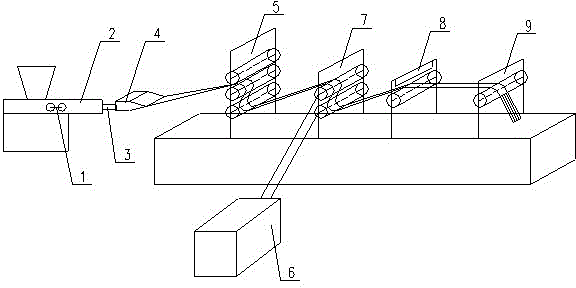

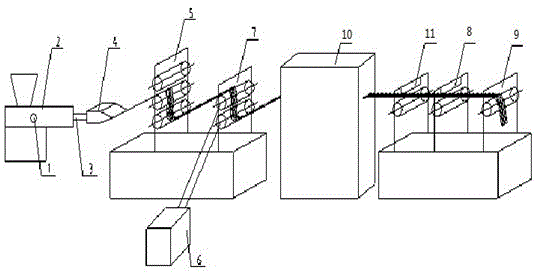

[0037] like figure 1 As shown, according to the preparation process of the plastic hook and loop fastener of the present invention, the toughened nylon material is melted in an extruder 2 equipped with a double coil (or single coil) 1, and extruded by a melt pump 3 After passing through the smooth sheet-shaped die 4, it becomes a continuous sheet and enters the traction mechanism. The tooth-forming roller 5, which is composed of a plurality of circular metal sheets with hook teeth, is rolled on the soft sheet to manufacture hooks. After the teeth, it enters the flat pressing roller 7 with an industrial chiller 6 for rolling and shaping, and then passes through the de-static machine 8 to remove dust. Buckle the product and finally pack it. The extruder 2 is equipped with a heating device, and the temperature under working conditions is 180°C-250°C (the temperature in the hot season is about 190°C, and the temperature in the cold season is about 240°C, and the temperature chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com