Pay-off rack for electric power construction

A technology for electric construction and pay-off rack, applied in the electric field, can solve the problems of short winding length, cable stacking and winding, reducing cable effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

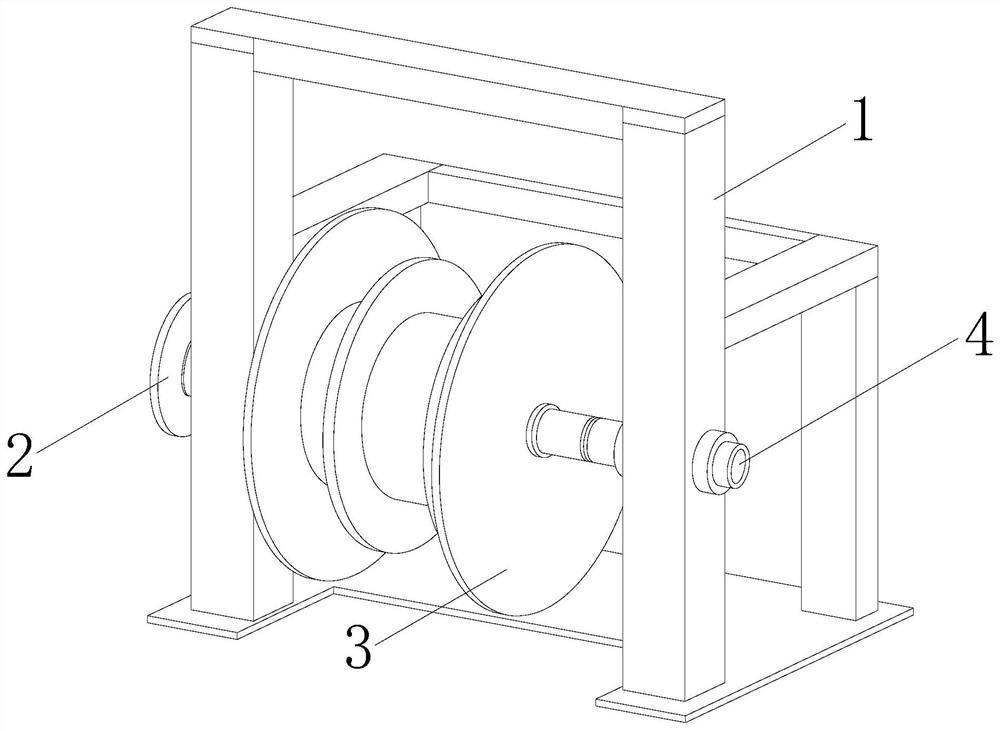

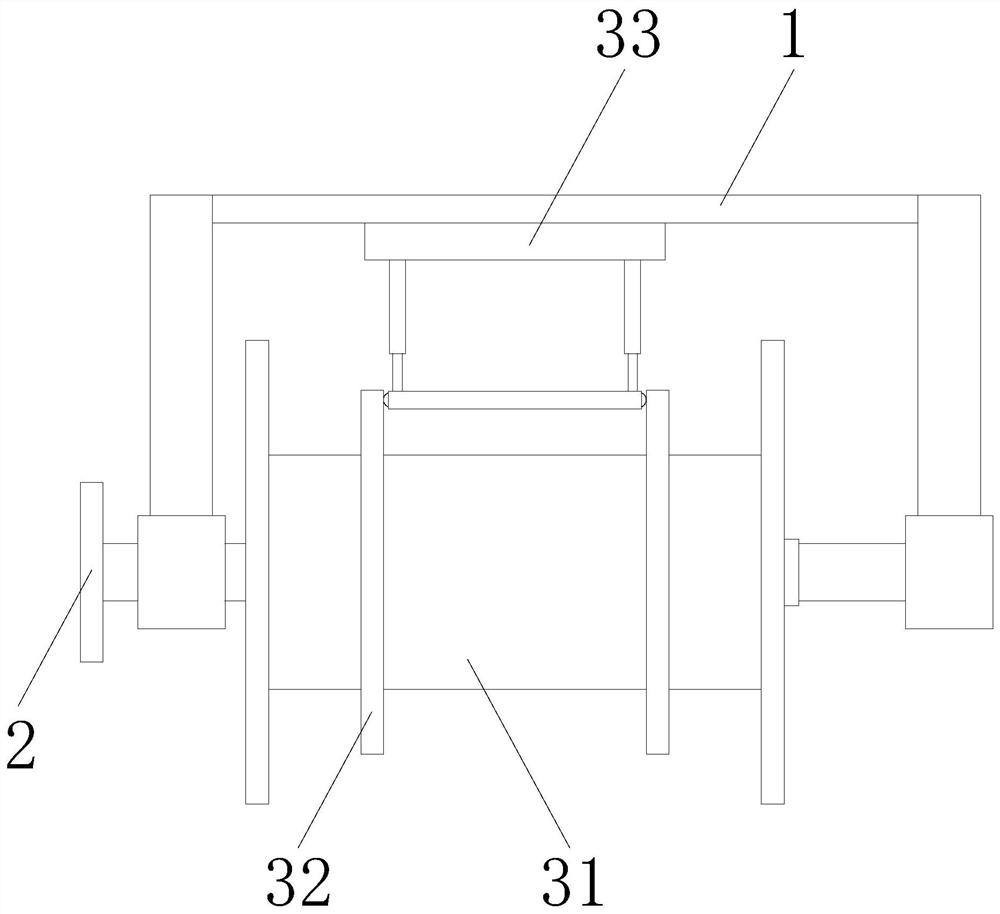

[0024] as attached figure 1 to attach Figure 6 Shown:

[0025] The present invention is a pay-off frame for electric power construction, its structure includes a support frame 1, a drive plate 2, an unwinder 3, and a connecting shaft 4, and a drive plate 2 is provided outside the left end of the support frame 1, and the drive plate 2 is connected to the release frame. The reel 3 rotates synchronously, the connecting shaft 4 runs through the inside of the unwinder 3, and the right end of the connecting shaft 4 is arranged inside the right end of the support frame 1, and the unwinder 3 includes a pay-off reel 31, a limit disc 32, a traction Device 33, the outer side of the pay-off reel is provided with a limit plate 32, and the connecting shaft 4 runs through the inside of the pay-off reel 31, the traction device 33 is located at the rear side of the pay-off reel 31, and the back of the traction device 33 is connected to the back of the support frame 1 The end phase is welded...

Embodiment 2

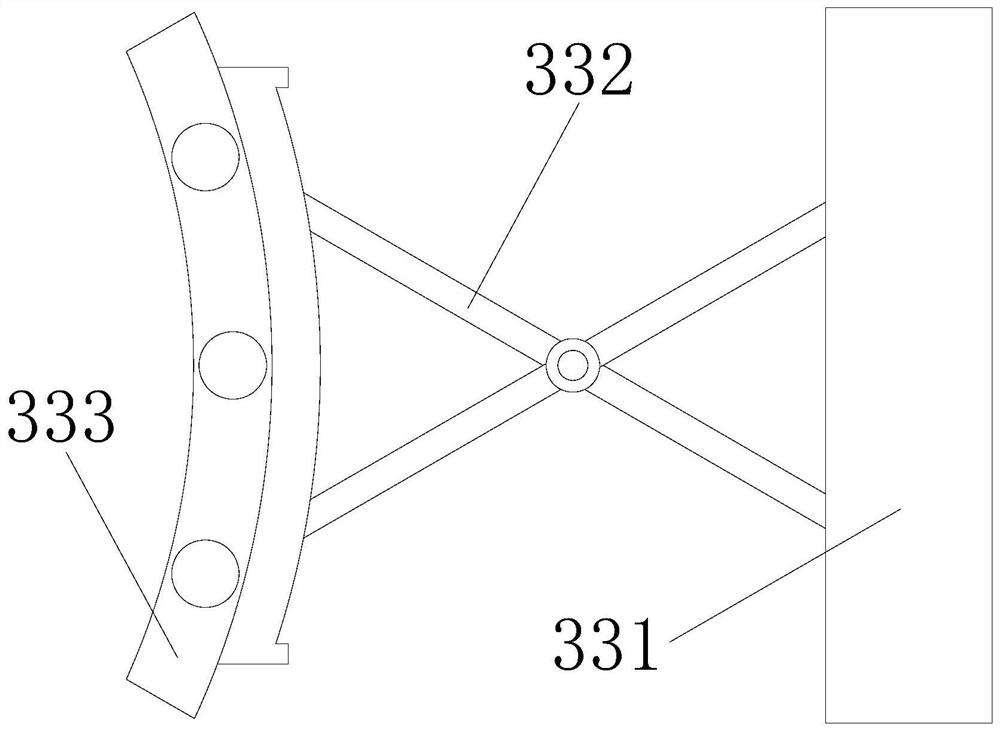

[0033] as attached Figure 7 to attach Figure 8 Shown:

[0034] Wherein, the abutment device 333 includes an abutment plate 33a, a ball 33b, and a snap-fit mechanism 33c, balls 33b are provided inside the front and rear ends of the abutment plate 33a, and the outer surface of the ball 33b is slidably connected with the inner surface of the limit plate 32, so The buckling mechanism 33c is embedded and installed on the left surface of the collision plate 33a. The collision plate 33a has an arc-shaped structure, and the curvature of the collision plate 33a matches the circular curvature of the pay-off reel 31, which is beneficial to the collision plate 33a. The surface of the cable wound on the outside of the coil 31 interferes, thereby applying traction to the cable.

[0035] Wherein, the fastening mechanism 33c includes a separation rod c1, a buckle c2, and a telescopic hose c3. The separation rod c1 is welded to the outer surface of the collision plate 33a, and the buckle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com