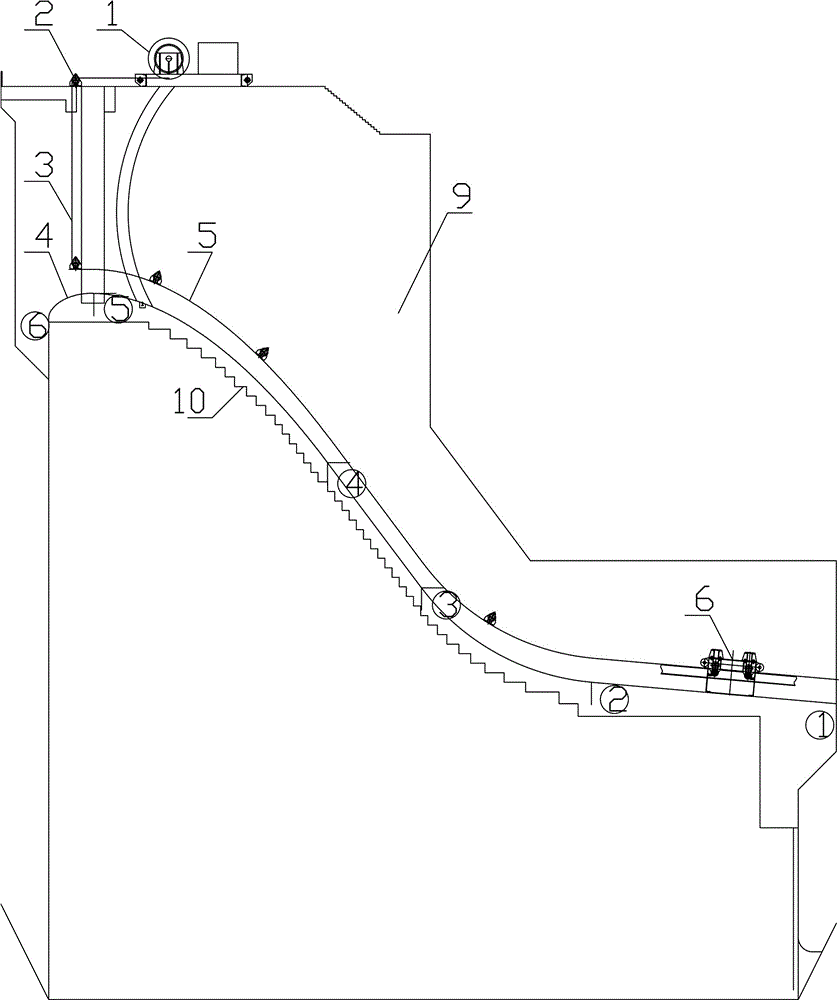

High and steep slope concrete sliding form traction control device

A technology of traction control device and traction device, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as bending track and complexity, and achieve the effects of avoiding bending damage, reducing wear, and being safe, practical and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

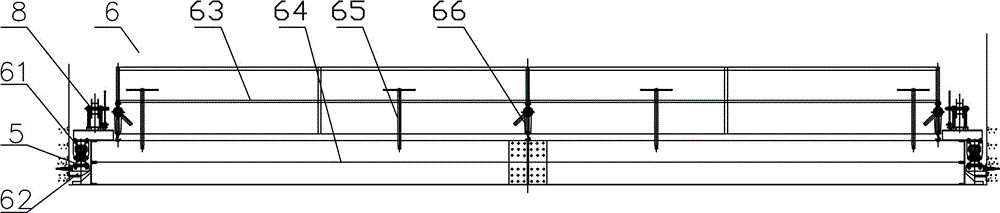

Method used

Image

Examples

Embodiment Construction

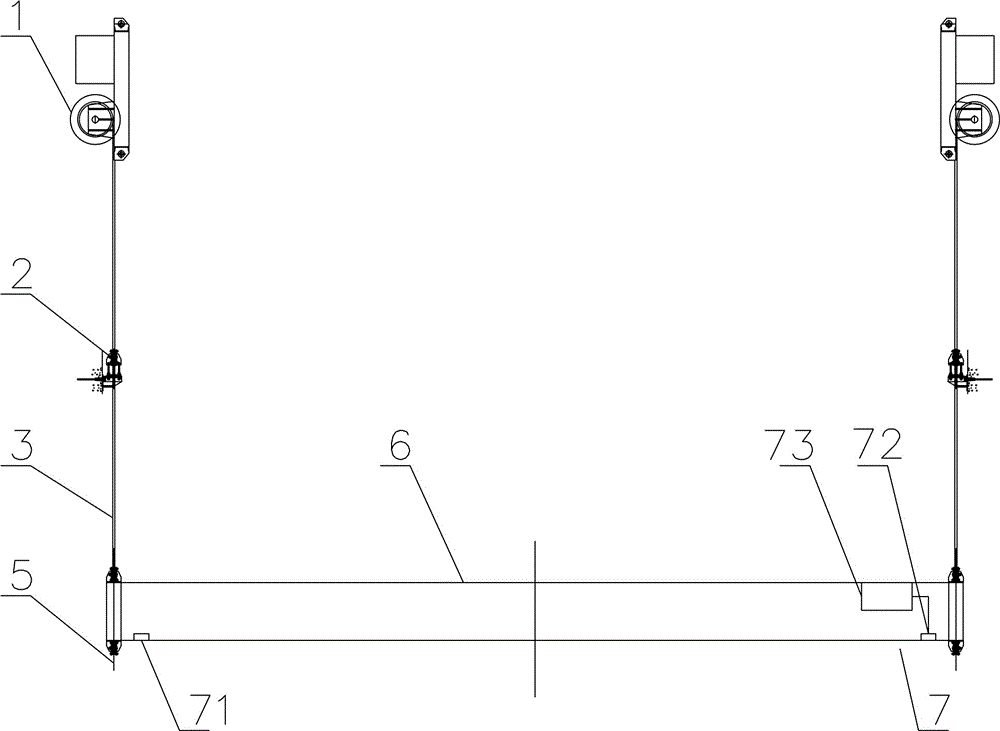

[0029] Such as image 3 Among them, a high and steep slope concrete sliding form traction control device, the two ends of the sliding form body 6 are connected with the traction device, and the sliding form body 6 is provided with a tension detection device 7;

[0030] The structure of the tension detection device 7 is as follows: the laser beam emitting device 71 is located at one end of the sliding form body 6 , the light receiving and detecting device 72 is located at the other end of the sliding form body 6 , and the light receiving and detecting device 72 is connected with the signal processing device 73 . With this structure, when the traction force of the traction device is consistent, the two ends of the sliding form body 6 are flush, and the laser beam emitted by the laser beam emitting device 71 falls on the light receiving and detecting device 72, and the signal processing device 73 can obtain the control signal, and the traction device continues Traction; when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com