Three-point force tester for cylindrical elastic element

A technology of elastic components and testing machines, which is applied in the testing of mechanical components, testing of machine/structural components, force/torque/power measuring instruments, etc. It can solve the problems of test point deviation, poor precision, inaccurate data, etc., to achieve The effect of consistent moving distance, accurate elastic force and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific features and performances of the present invention are further described by the following embodiments in conjunction with the accompanying drawings.

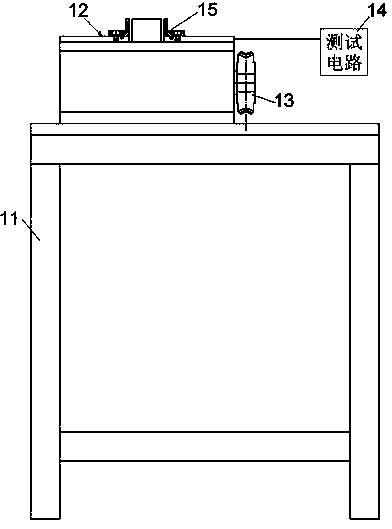

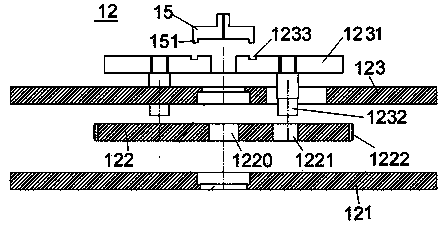

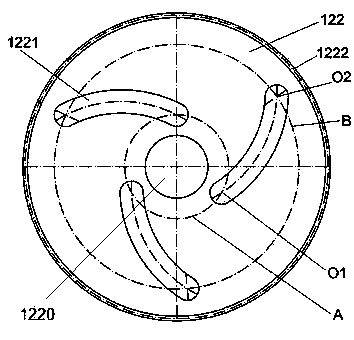

[0029] see figure 1 , figure 2 ,in, figure 1 is a structural schematic diagram of an embodiment of the present invention, figure 2 It is an exploded schematic diagram of an embodiment of the test component in the present invention. A three-point force testing machine for a cylindrical elastic element of the present invention includes a frame 11 , a testing component 12 , a transmission component 13 and a testing circuit 14 . Please refer to figure 2 , the test component 12 includes a chassis 121 , a turntable 122 , and a panel 123 . The panel 123 and the chassis 121 are fixed on the frame at intervals up and down, and the turntable 122 is provided with a shaft hole 1220, which is arranged between the chassis and the panel through the central axis, and the turntable is driven by the transmission part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com