Array substrate manufacturing method, array substrate and display device

A technology of an array substrate and a manufacturing method, which is applied in the display field, can solve the problems affecting the product yield rate and data line disconnection defects, and achieves the effect of reducing the probability of disconnection defects and improving the yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

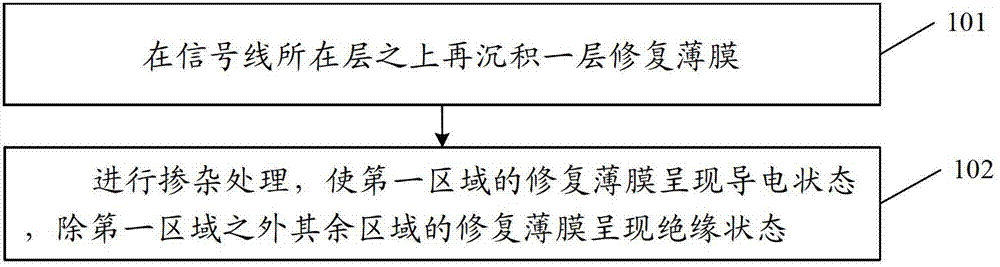

[0050] An embodiment of the present invention provides a method for manufacturing an array substrate. The array substrate includes: a display unit and signal lines for providing display signals and control signals to the display unit, such as figure 1 As shown, the method includes:

[0051] 101. Form a repair film on the layer where the signal line is located, and the repair film is a transparent conductive doped semiconductor film or a transparent insulating semiconductor film;

[0052] The signal lines in this step may be data lines, or gate lines, or common electrode lines, or two of them are in the same layer.

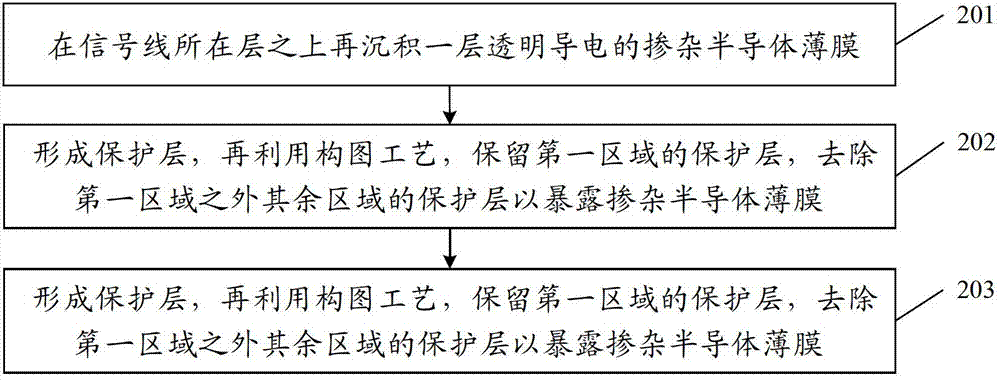

[0053] In this step, after the signal line is formed, a repair film layer is formed. The repair film layer can be a transparent conductive doped semiconductor film, such as an amorphous silicon (a-si) material doped with boron B or phosphorus P, or Tin-doped indium oxide (Indium Tin Oxides, ITO), or N-type or P-type doped thin films of materials such as ZnO, ZnS, ...

Embodiment 2

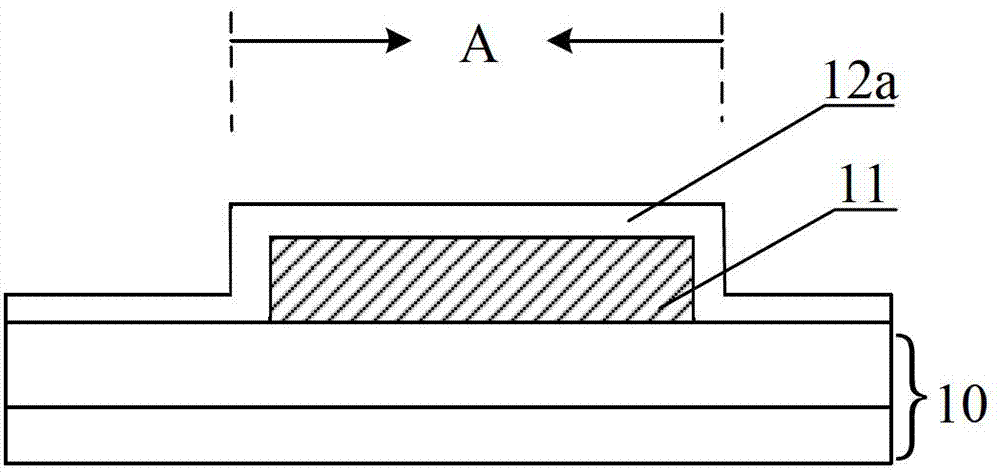

[0086] Such as Figure 6 and Figure 7 As shown, the embodiment of the present invention also provides an array substrate, including: a display unit 15 and a signal line that provides display signals and control signals to the display unit 15, and the signal line can be a data line, or a gate line, or a common electrode line , for example, the signal line is the data line 112 in the figure,

[0087] A repair film 12 is arranged on the layer where the signal line (data line 112) 11 is located, and,

[0088] The repair film 12 is in a conductive state in the first region A, and is in an insulating state in other regions except the first region A, where the first region A is the region corresponding to the signal line 11 .

[0089] In this embodiment, the repair film 12 acts as a passivation layer at the same time, the repair film 12 above the data line (the first region A) is in a conductive state, and the rest of the region (except the first region A) the repair film 12 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com