Reaction heating method and device

A thermal method and reaction technology, applied in lighting and heating equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of increasing operating costs, dust emissions, catalyst fragmentation, etc., and achieve high heat transfer efficiency and fluidization. The effect of improving mixing efficiency and shortening height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

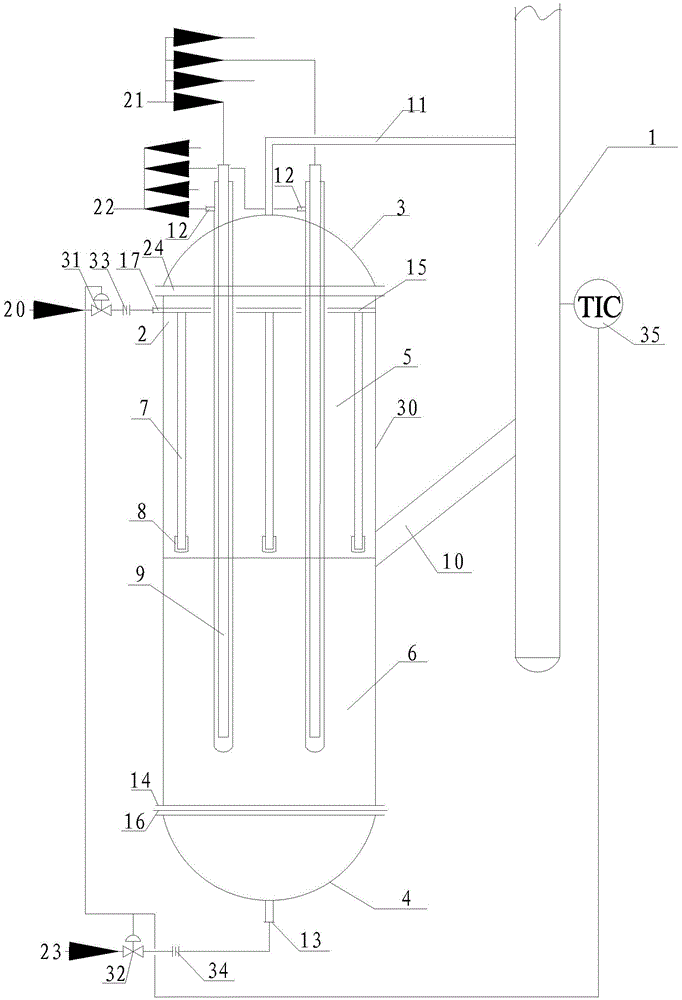

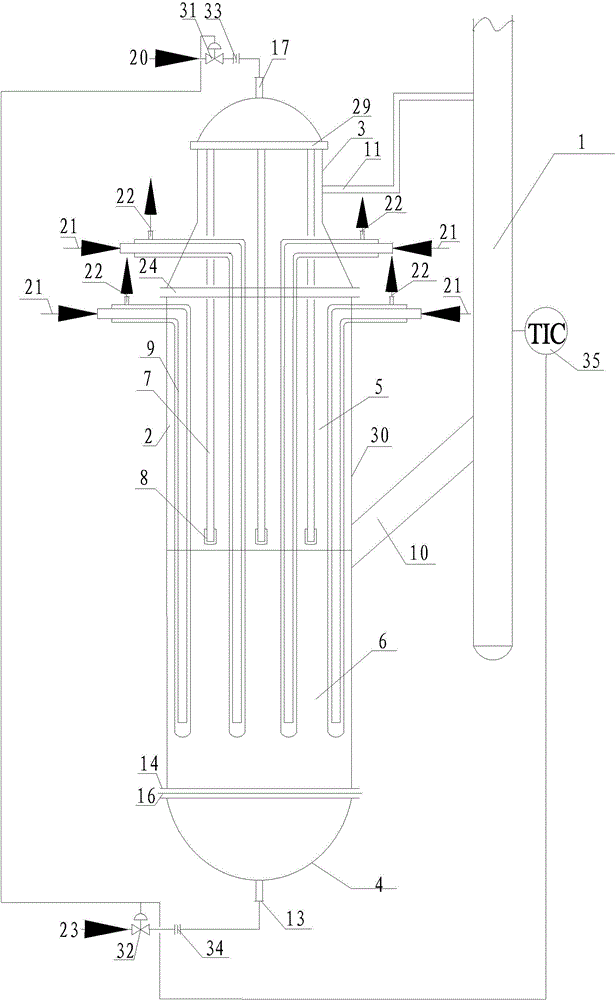

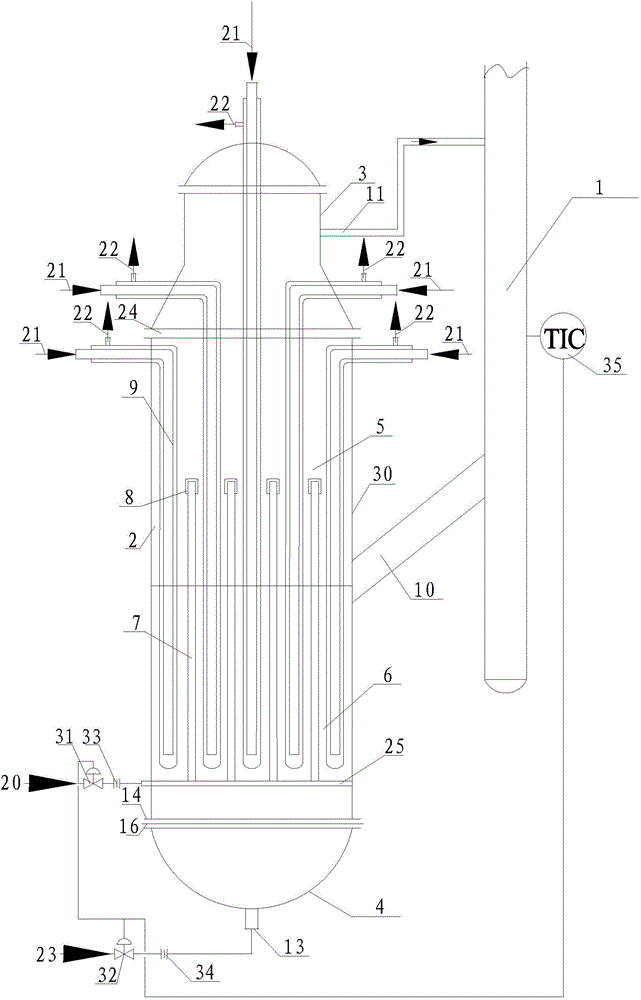

[0038] As shown in Figure 7, the reaction heat extraction method and equipment of a methanol-to-ethylene catalyst regenerator, the heat load is 25MW, and 4.0MPa saturated steam 27 is produced. The reaction heat extraction method and equipment: the catalyst regeneration temperature is 660°C, and the diameter of the catalyst connecting pipe 10 is 1300mm The angle between the center line of the catalyst connecting pipe 10 and the axis of the reaction heat extraction equipment is 50°; the diameter of the main shell 30 is 2200mm, the total height of the heat transfer area of the heat exchange tube 9 is 6m, the height of the lower heat transfer area 6 is 2.5m, and the height of the upper heat transfer area 5 3.5m; the lower end of the heat exchange tube 9 is 300mm from the lower distributor; 34 heat exchange tubes; the heat exchange tube 9 is in the form of inner and outer tubes, and the outer tube specification is DN150; the inner tube is DN80; the total heat exchange area is 96㎡; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com