A swirling air flow fluidization device and a fluidization method for sheet materials

A fluidization device and technology of rotating airflow, applied in the field of fluidization, can solve problems such as difficulty in reaching a fluidized state, and achieve the effects of improving density and uniformity, simplifying fluidization methods, and solving fluidization problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

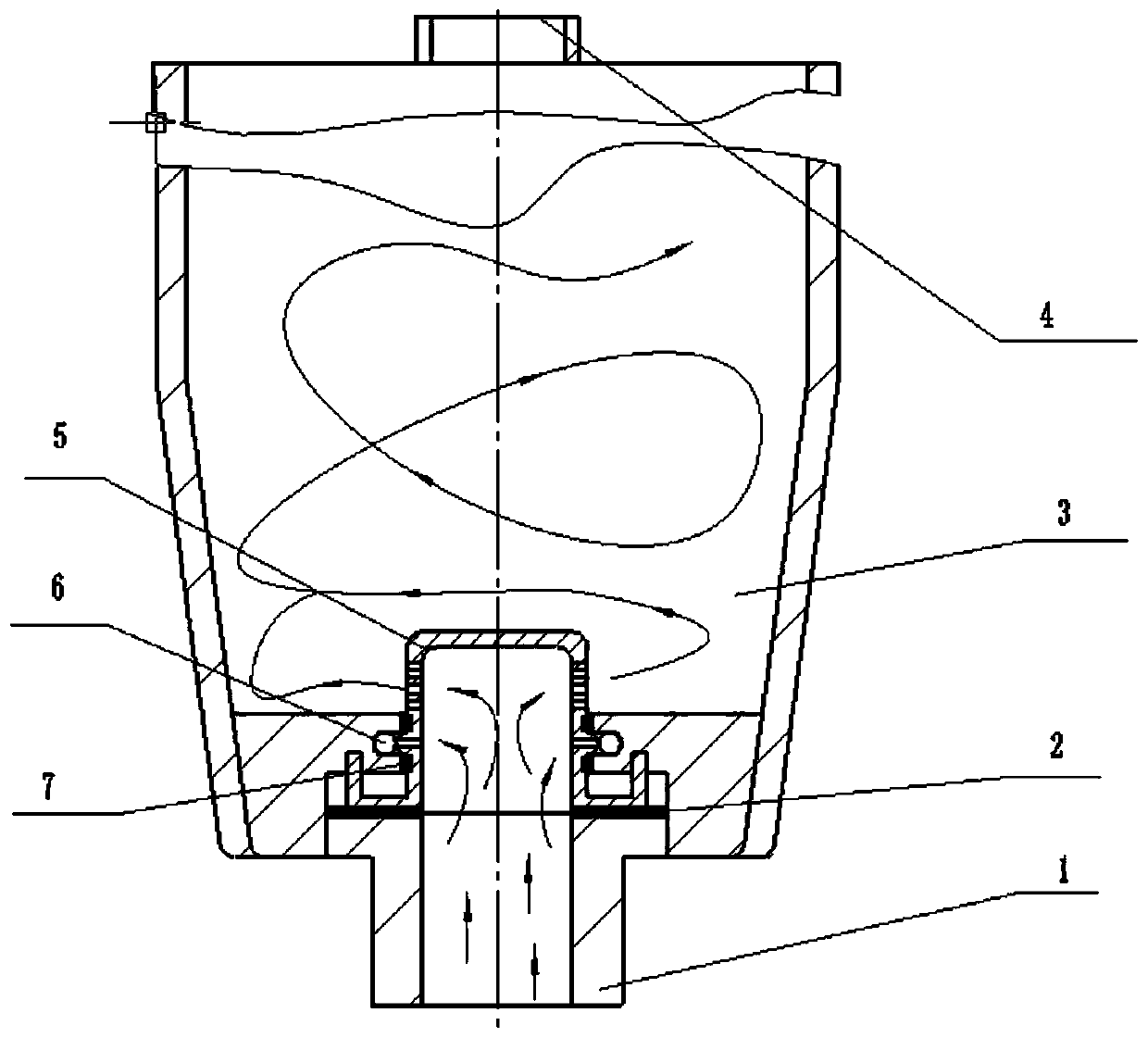

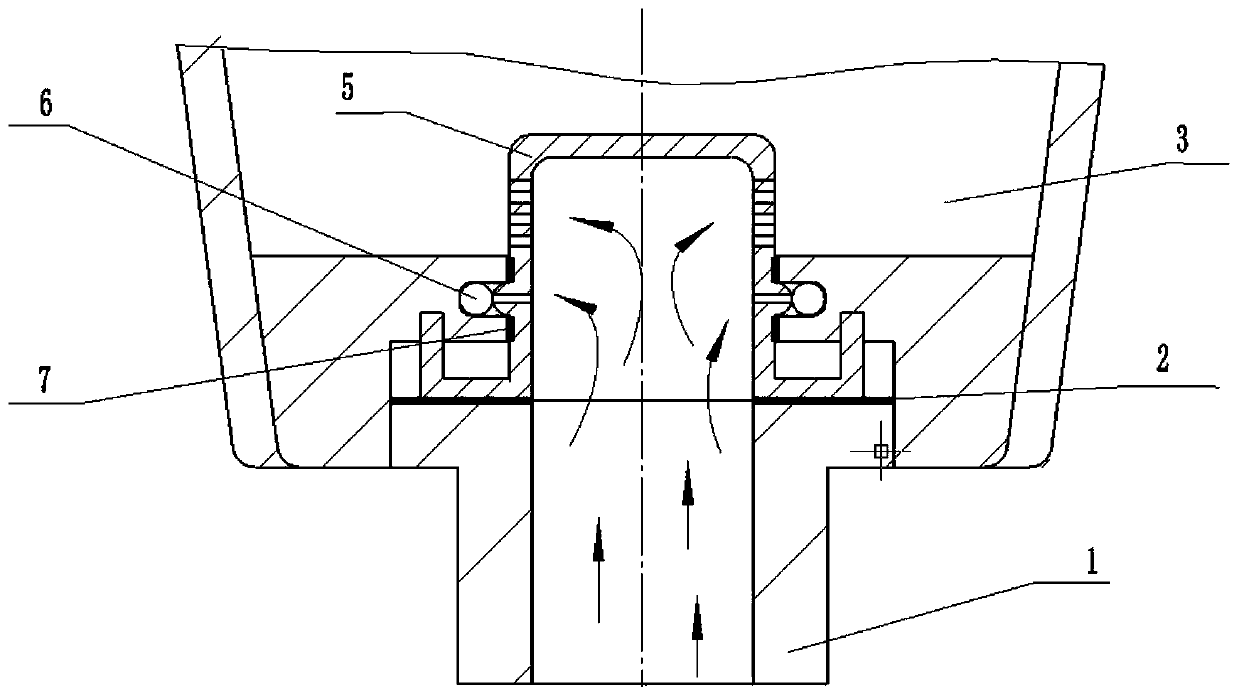

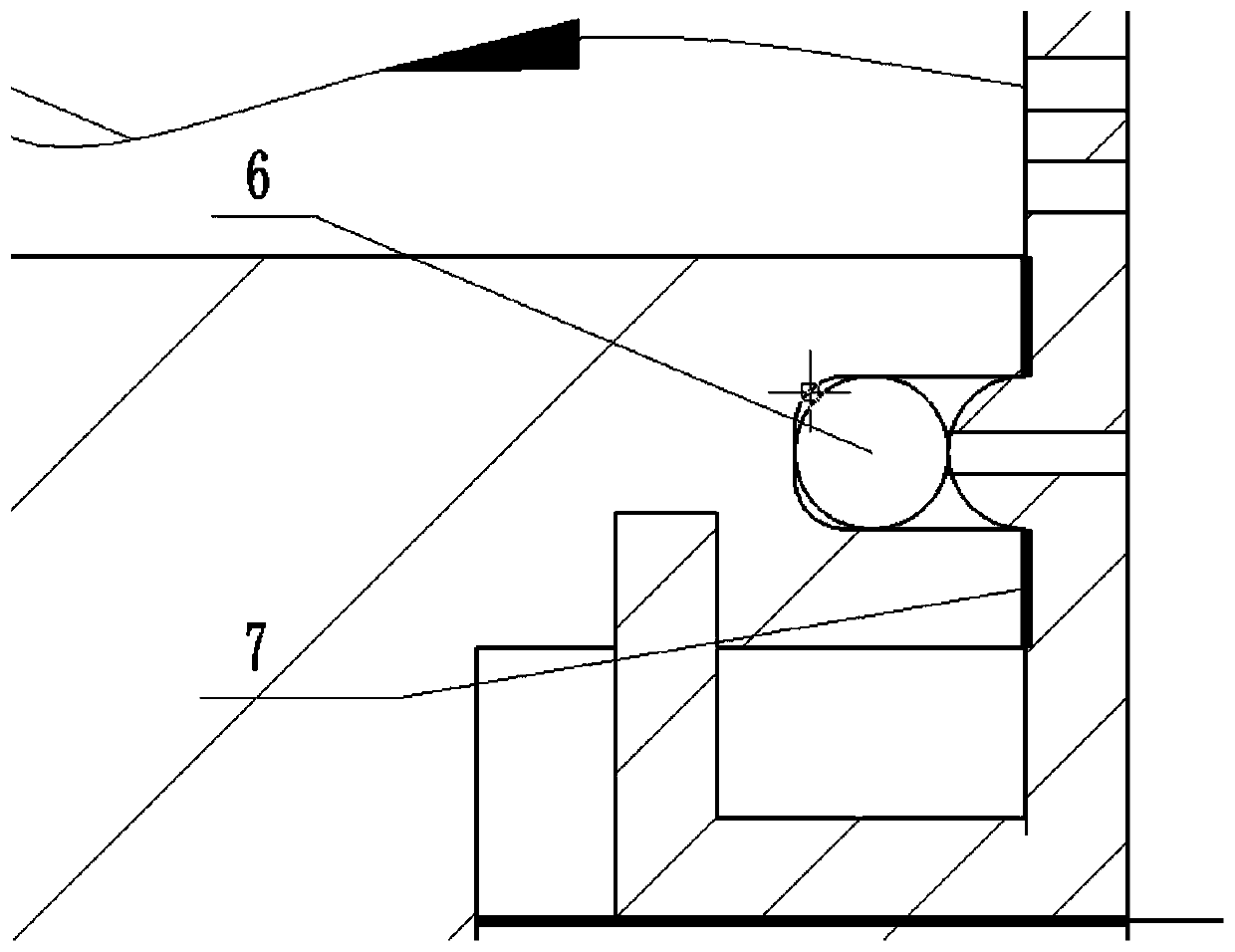

[0040] Weigh 400g of flake aluminum powder with an average particle size of 30 μm and an aspect ratio of 31, such as figure 1 Add flake aluminum powder to the bottom of the fluidized bed through the feeding port 4 at the upper part of the fluidized bed. Then turn on the vacuum pump to evacuate the fluidized bed into a vacuum state, from the air vent in the fluidized bed, such as figure 1 The 1 in is the air vent, and the nitrogen gas is passed into the fluidized bed, and the flow rate is determined by the pressure gauge, and the flow rate of the fluidized gas is adjusted to 4.0m 3 / h.

[0041] When Uo

Embodiment 2

[0047] Weigh 450 g of flake glass with an average particle diameter of 30 μm and an aspect ratio of 30, and add the flake glass to the bottom of the fluidized bed from the upper feed port in the fluidized bed. Then turn on the vacuum pump, and the fluidized bed is evacuated into a vacuum state. After the vacuum state, nitrogen gas is passed into the fluidized bed from the air vent in the fluidized bed, and the feed rate is determined by the pressure gauge, and the feed rate of the fluidized gas is adjusted to be 4.5m 3 / h. Through observation, the sheet glass in the fluidized bed can get a better fluidized state, and the gas distributor can rotate to drive the airflow to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com