Efficient and stable visible light polyaniline group nanometer silver phosphate compound photocatalyst and preparation method thereof

A polyaniline-based, visible light technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Improve stability, reduce photocorrosion, and improve catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

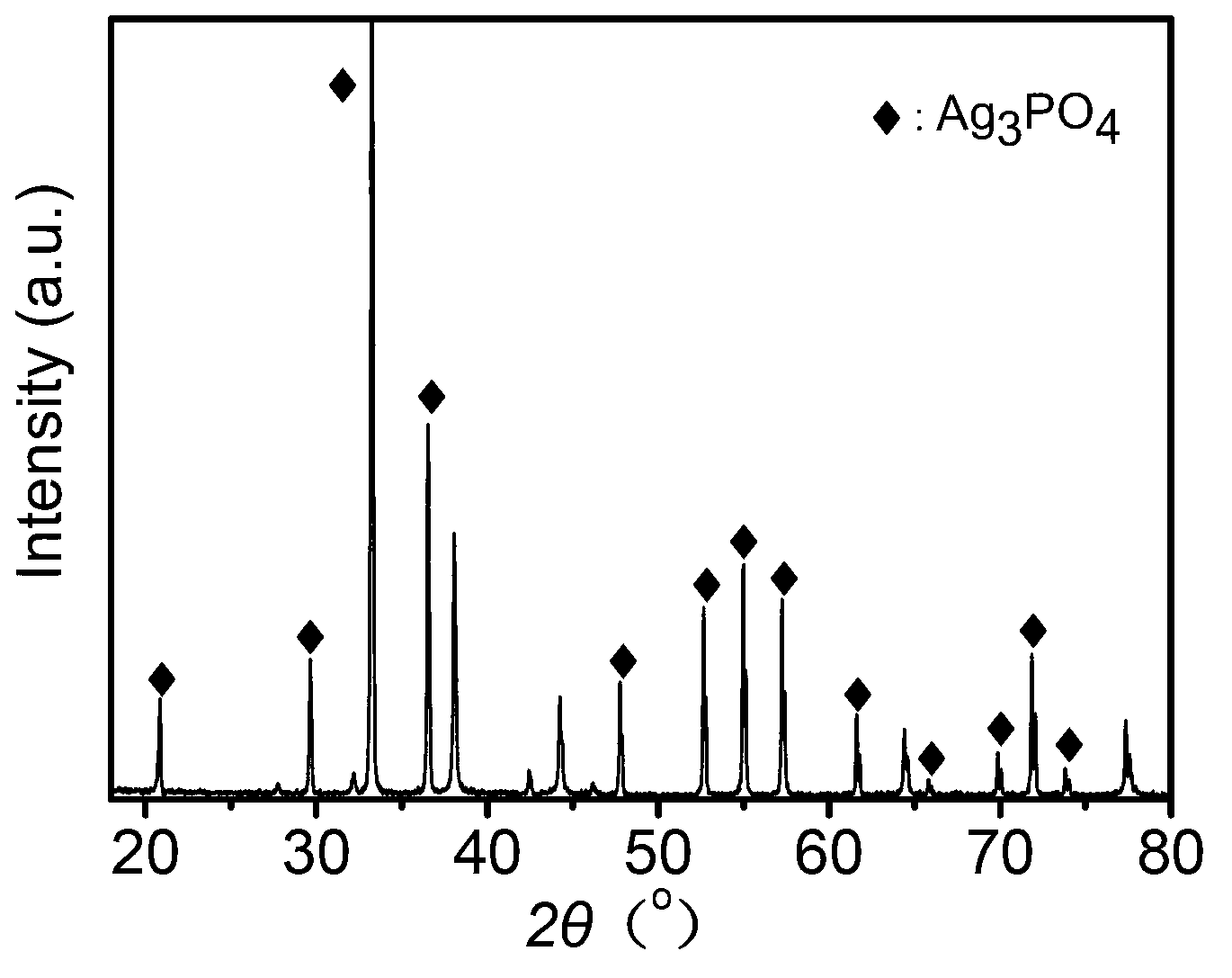

Embodiment 1

[0016] Take 0.6ml of aniline from secondary rectification and add it to 20ml 1mol L -1 Hydrochloric acid solution, and cooled to 0 ° C, slowly dropwise added 0.5g·mL -1 The ammonium persulfate solution was reacted for 6 hours and terminated, filtered, washed with water, and dried to obtain chain polyaniline; ultrasonically dispersed 0.1 g of chain polyaniline in 75 g of toluene solvent; added 1.5 g of silver nitrate, 10 g of oleylamine, 15g of ethanol, stirred for 1.5h; then added 1.5g of phosphoric acid, stirred for 18h; finally it was filtered, the precipitate was collected, washed with alcohol, washed with water, and dried to obtain a polyaniline-based nano-silver phosphate composite photocatalyst, polyaniline and Ag 3 PO 4 The mass ratio is 1:12. The prepared polyaniline-based nano-silver phosphate composite photocatalyst was used to degrade rhodamine B under visible light to measure its catalytic activity. It was found that the dye degradation rate exceeded 98% within 8...

Embodiment 2

[0018] Take 0.6ml of aniline from secondary rectification and add it to 20ml 1mol L -1 Hydrochloric acid solution, and cooled to 0 ° C, slowly dropwise added 0.5g·mL -1 Terminate the ammonium persulfate solution after reacting for 6 hours, filter, wash with water, and dry to obtain chain polyaniline; ultrasonically disperse 0.08 g of chain polyaniline in 75 g of dimethylformamide solvent; add 1.5 g of silver nitrate, 10g oleic acid, 15g ethanol, stirred for 1.5h; then added 1.5g of phosphoric acid, stirred for 18h; finally it was filtered, the precipitate was collected, washed with alcohol, washed with water, and dried to obtain a polyaniline-based nano-silver phosphate composite photocatalyst, Polyaniline and Ag 3 PO 4 The mass ratio is 1:15. The prepared polyaniline-based nano-silver phosphate composite photocatalyst degraded rhodamine B under visible light to measure its catalytic activity. It was found that the dye degradation rate exceeded 98% within 12 minutes, and re...

Embodiment 3

[0020] Take 0.6ml of aniline from secondary rectification and add it to 20ml 1mol L -1 Hydrochloric acid solution, and cooled to 0 ° C, slowly dropwise added 0.5g·mL -1 Terminate the ammonium persulfate solution after reacting for 6 hours, filter, wash with water, and dry to obtain chain polyaniline; ultrasonically disperse 0.06g chain polyaniline in 30g toluene solvent; add 1.5g silver nitrate and 7.5g oleic acid to it , 3g ethanol, stirred for 1h; then added 1.5g of phosphoric acid, stirred for 12h; finally it was filtered, the precipitate was collected, washed with alcohol, washed with water, and dried to obtain a polyaniline-based nano-silver phosphate composite photocatalyst, polyaniline and Ag 3 PO 4 The mass ratio is 1:20. The prepared polyaniline-based nano-silver phosphate composite photocatalyst was used to degrade rhodamine B under visible light to measure its catalytic activity. It was found that the dye degradation rate exceeded 98% within 16 minutes, and remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com