Green tea yogurt and preparation method thereof

A technology for yogurt and green tea, applied in milk preparations, dairy products, applications, etc., can solve the problems of less tea efficacy substances, delayed bitterness, easy precipitation of whey, etc., and achieves increased solubility, fine texture, and product quality. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

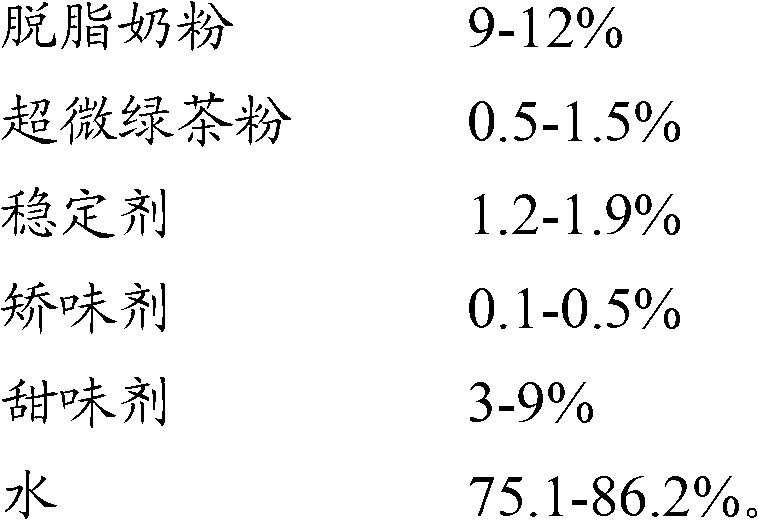

[0042] The raw materials of 1kg green tea yogurt include: skimmed milk powder 100g, superfine green tea powder 5g, stabilizer (12g whey protein concentrate with 80% protein content), flavoring agent (β-cyclodextrin 1g), sweetener (white 50g of granulated sugar, 0.3g of acesulfame potassium), and the balance is water. Wherein, the ultrafine green tea powder has a particle size of 500 mesh.

[0043] The preparation method comprises the following steps:

[0044] (1) Preparation of ultrafine green tea powder solution: Disperse 5g of green tea powder in 495g of water, filter with a 50-mesh filter cloth, take the filtrate, and homogenize twice with a homogenizer (homogenizing pressure 100MPa) to obtain ultrafine green tea powder solution;

[0045] (2) Preparation of reconstituted milk: Dissolve skimmed milk powder, stabilizers, flavoring agents and sweeteners in 336.7 g of 40°C water according to the formula, and circulate and stir for 15 minutes to fully hydrate the liquid to obt...

Embodiment 2

[0050] The raw materials of 1kg of green tea yogurt include: 120g of skim milk powder, 10g of superfine green tea powder, stabilizer (2g of modified starch, 10g of concentrated whey protein with a protein content of 80%), flavoring agent (3g of β-cyclodextrin), sweetener Flavoring agent (white sugar 50g, acesulfame potassium 0.4g), the balance is water. Wherein, the ultrafine green tea powder has a particle size of 600 mesh.

[0051] The preparation method comprises the following steps:

[0052] (1) Preparation of superfine green tea powder solution: Disperse 10g of green tea powder in 490g of water, filter with a 50-mesh filter cloth, take the filtrate, and homogenize twice with a homogenizer (homogeneous pressure 90MPa) to obtain superfine green tea powder solution;

[0053] (2) Preparation of reconstituted milk: Dissolve skimmed milk powder, stabilizers, flavoring agents and sweeteners in 314.6 g of water at 40°C according to the formula, and circulate and stir for 15 min...

Embodiment 3

[0058] The raw materials of 1kg green tea yogurt include: 110g skimmed milk powder, 12g superfine green tea powder, stabilizer (2g soybean polysaccharide, 10g whey protein concentrate with 80% protein content), flavoring agent (4g β-cyclodextrin), sweetener Flavoring agent (white sugar 30g, aspartame 0.4g), the balance is water. Wherein, the ultrafine green tea powder has a particle size of 800 mesh.

[0059] The preparation method comprises the following steps:

[0060] (1) Preparation of superfine green tea powder solution: Disperse 12g of green tea powder in 488g of water, filter with a 60-mesh filter cloth, take the filtrate, and homogenize it 3 times with a homogenizer (homogeneous pressure 80MPa) to obtain superfine green tea powder solution;

[0061] (2) Preparation of reconstituted milk: Dissolve skimmed milk powder, stabilizers, flavoring agents and sweeteners in 343.6 g of water at 40°C according to the formula, and circulate and stir for 15 minutes to fully hydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com