Device and method for supercritical drying of microwave excitation

A supercritical drying and microwave generating device technology, which is applied in the processing of photosensitive materials, can solve problems such as lodging or adhesion, nano-pattern fracture, etc., and achieve the effects of short drying time, low energy consumption and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

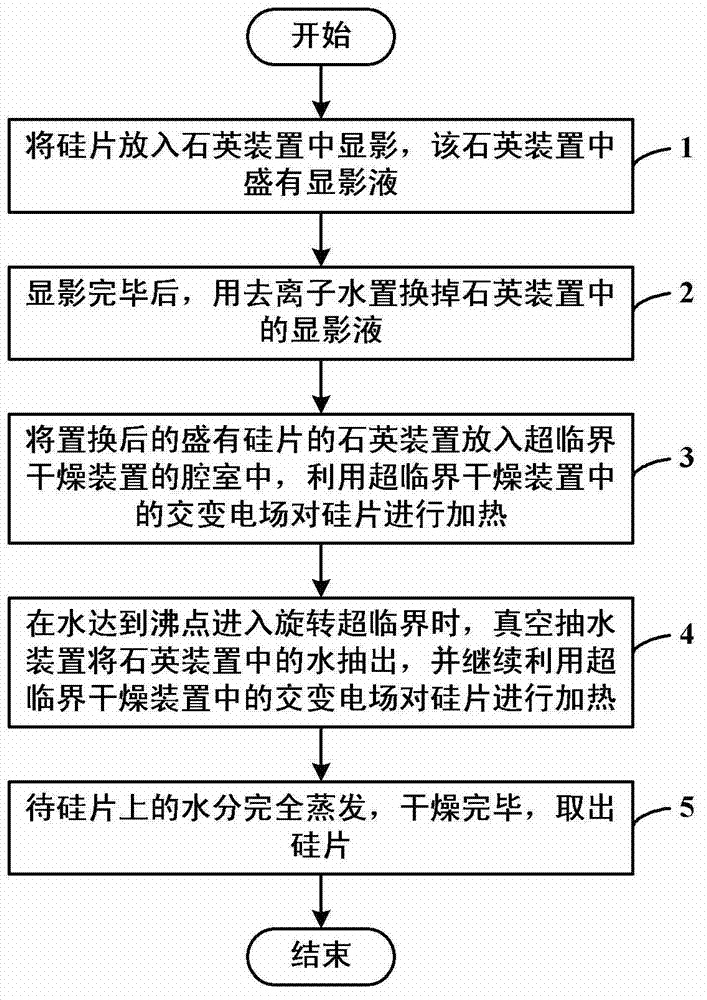

[0047] Embodiment 1: Microwave drying width is 14.9nm HSQ adhesive lines

[0048] Step 1: Put a 2-inch, 4-inch or 8-inch silicon wafer with a photoresist pattern into a quartz device for development, and the quartz device has a developer suitable for HSQ glue;

[0049] Step 2: After the development is completed, replace the developer in the quartz device with deionized water;

[0050] Step 3: Put the replaced quartz device with the silicon wafer in figure 1 In the chamber of the microwave-excited supercritical drying device shown, the alternating electric field in the supercritical drying device is used for heating. The specific heating principle is: water molecules are polar molecules, which change rapidly with the direction of the alternating electric field , the polarity of the water molecules also changes direction. When the frequency of the change becomes faster and faster, the water molecules start to rotate at a high speed, the kinetic energy increases, the friction an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com