LED light source module and heat radiator thereof

A technology of LED light sources and LED components, applied in the direction of light sources, electric light sources, point light sources, etc., can solve problems such as light distribution ghosting, structure and driving power limitations, and light spots, and achieve high insulation safety and unique fixing methods , good optical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

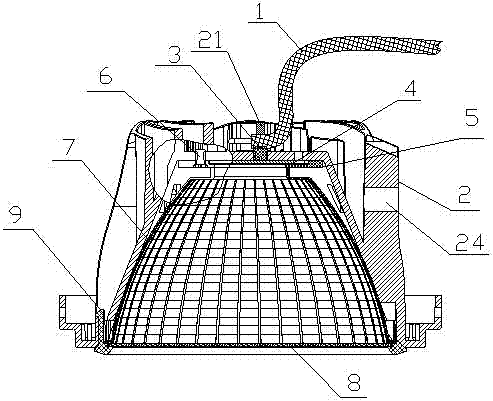

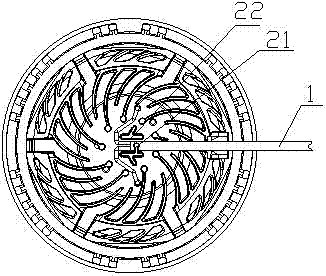

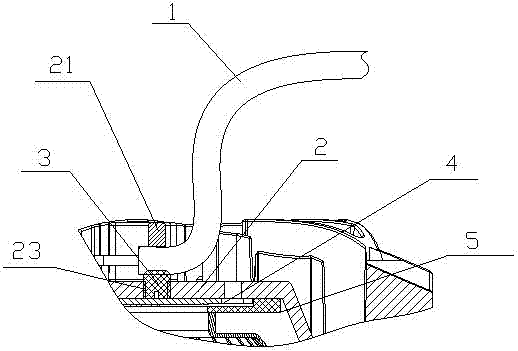

[0022] Such as figure 1 As shown, a light source module using LED as light source, such as AR111 light source module or MR16 light source module, includes: wire 1, radiator 2, plastic screw 3, LED component 4, pressure plate 5, screw 6, reflective cup 7. The light-transmitting plate 8 and the surface cover 9, wherein, the electric wire 1 is fixed on the corresponding fixed structure of the radiator 2 through the plastic screw 3, and the fixed structure is innovatively designed and molded on the radiator 2, which saves a wire buckle and It can effectively prevent the wires from loosening due to external force, and at the same time, the heat sink 2 is designed with ventilation holes to ensure that the heat of the LED is quickly discharged through convection, and the temperature difference between the inside and outside is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com