Horizontal aerobic fermentation reactor and aerobic fermentation reaction method

A kind of aerobic fermentation and reactor technology, which is applied in application, fertilization equipment, climate change adaptation, etc., can solve the problems of high drum rotation drive power, high equipment manufacturing cost, and large floor area, and achieve low drive power and occupying a large area. The effect of small area and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

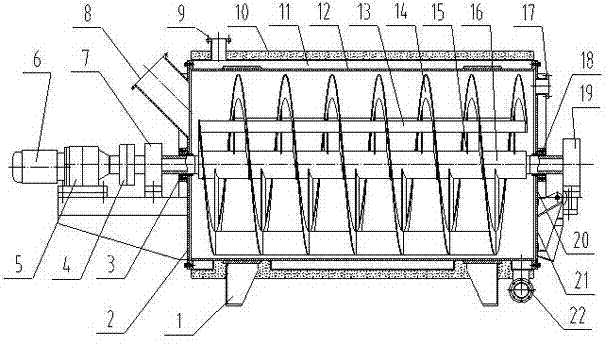

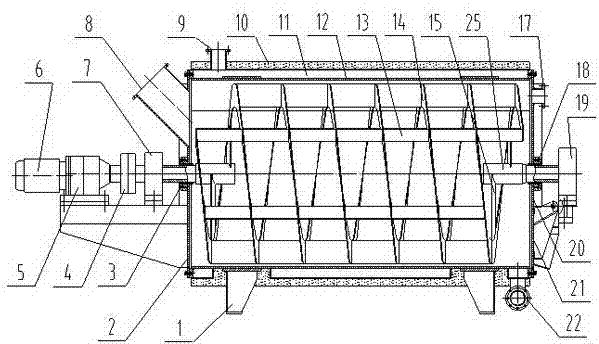

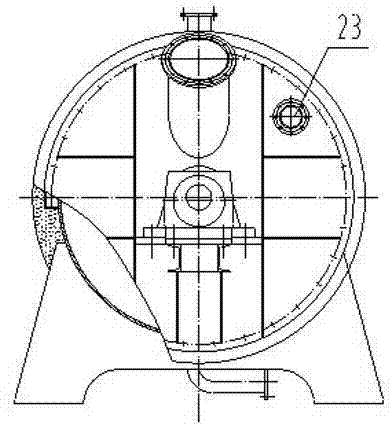

[0036] According to the attached figure 1 , attached image 3 , attached Figure 4 Example 1 of the present invention will be described. The stirring device used in Example 1 is provided with a rotating shaft.

[0037] A horizontal aerobic fermentation reactor with fermentation temperature control, which consists of a horizontal cylinder, a stirring device, end covers and seals on both sides, inlet and outlet holes, ventilation pipe flanges, a driving device, a discharging device, and a jacket and other components.

[0038] The lying cylinder 12 is supported by the legs 1 and is fixed. There are at least two groups of legs 1, and its quantity depends on the length of cylinder 12 lying down.

[0039] Both sides of the horizontal cylinder 12 are respectively provided with a feed-side end cover 2 and a discharge-side end cover 20, and the horizontal cylinder 12 is fixedly connected with the end covers on both sides.

[0040] Stirring device is made up of lifting plate 13, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com