Welding process information acquisition and quality monitoring device and method based on Ethernet

A welding process and quality monitoring technology, applied in welding equipment, arc welding equipment, electrical program control, etc., can solve the problems of inconvenient data collection and monitoring, and achieve the effect of quality monitoring, cost reduction, and online monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] This embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and processes.

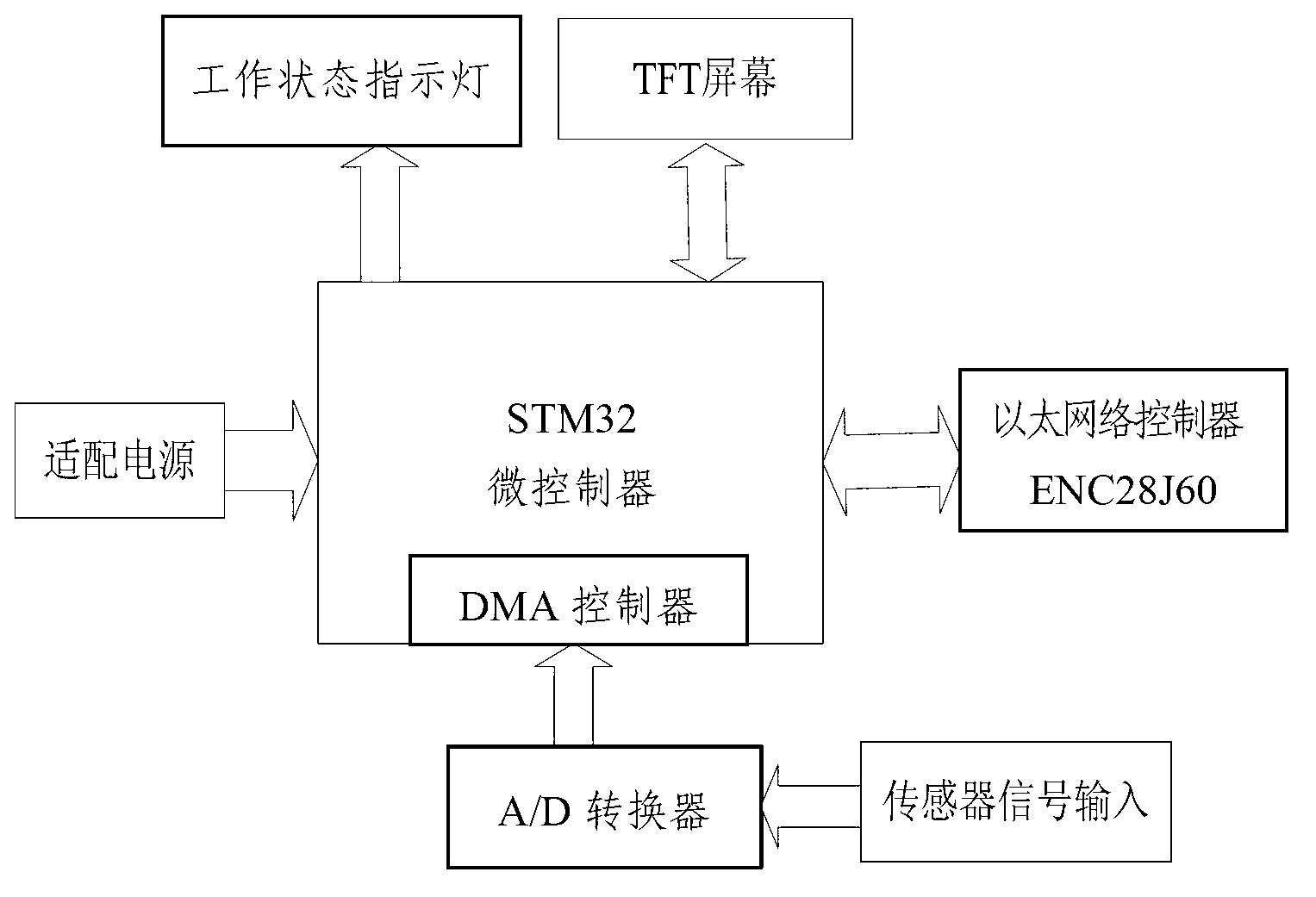

[0063] The present invention selects ARM framework chip STM32F103 micro-controller of STMicroelectronics Company, the network controller selects Ethernet controller ENC28J60; data display adopts TFT2.4-inch liquid crystal display screen.

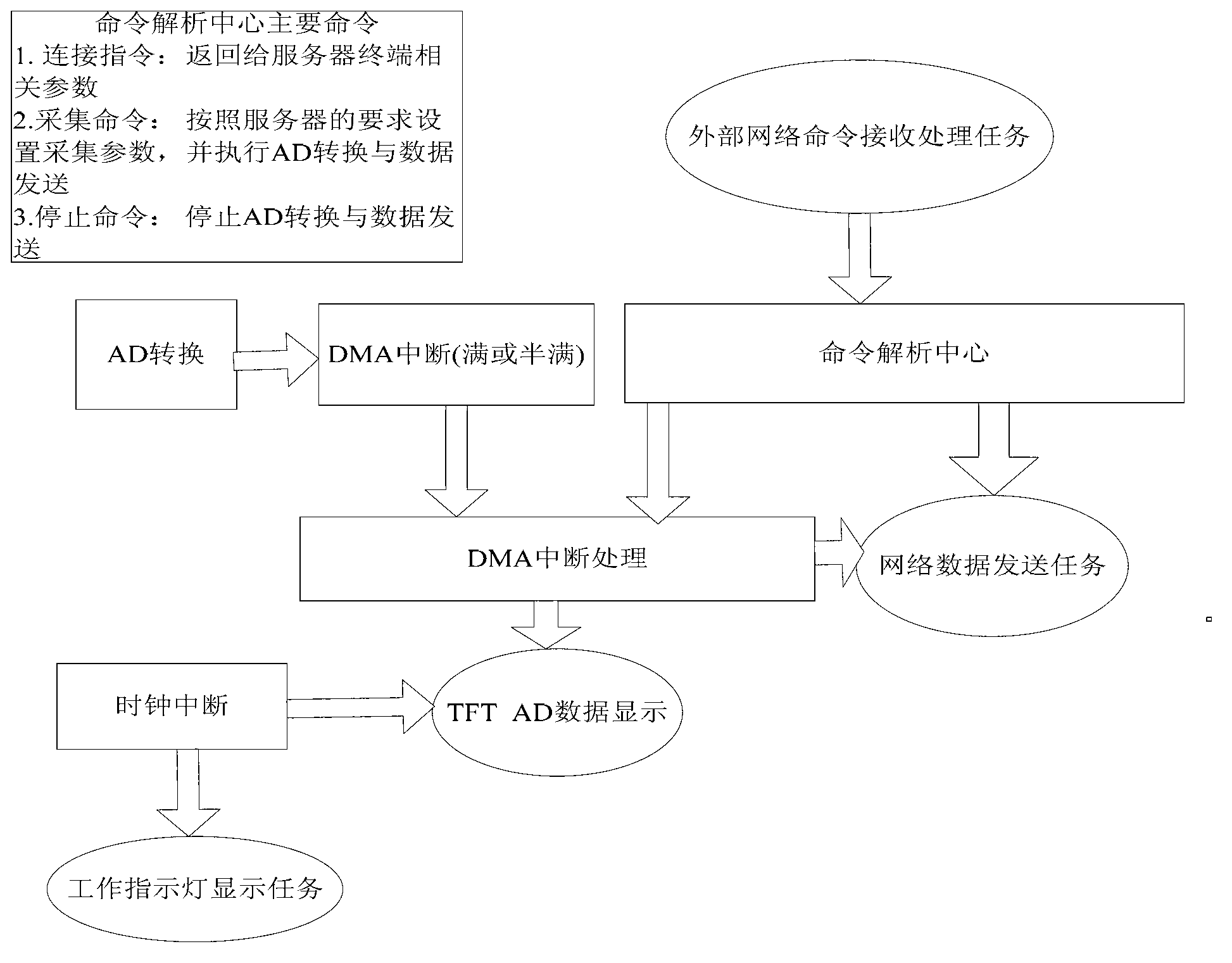

[0064] The control process of the data collection terminal: the control of the data collection terminal adopts the multi-task method, and the data transmission adopts the connectionless UDP protocol. The data acquisition terminal works in the Ethernet environment, and the data transmission is relatively stable, so there is no need to use the TCP protocol for reliable transmission (the "three-way handshake" of the TCP protocol increases the amount of additional data). The main tasks of controlling the data acquisition terminal are as follows: figure 2 As shown, it includes: wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com