Investment casting method of heat-resistant steel exhaust manifold for automobile

An exhaust manifold and investment casting technology, which is applied in the field of investment casting, can solve the problems of many combined sand cores, prone to shrinkage porosity, and many loose sand cores, etc., and achieves improved product process yield and machining allowance. Reduced, good surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

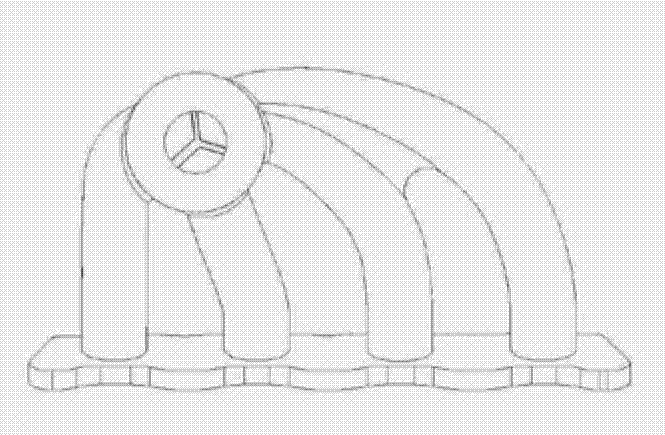

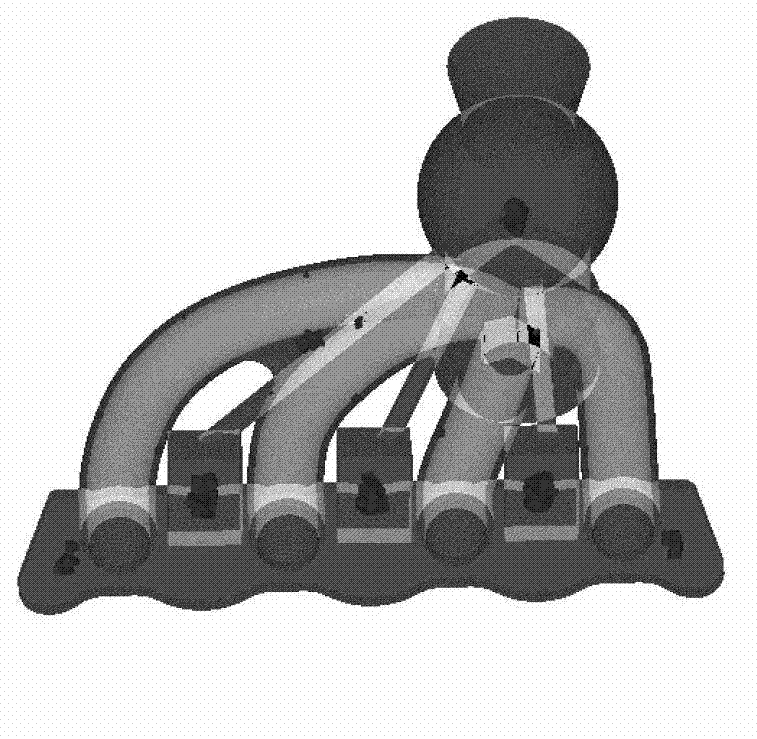

Image

Examples

Embodiment 1

[0027] The heat-resistant steel exhaust manifold of automobile engine adopts investment casting process and steps as follows:

[0028] 1. Manufacture of wax mold: using soluble urea core method,

[0029] The core manufacturing process is as follows:

[0030] 1) Core material: urea; 2) Molding method: free casting;

[0031] 3) Melting temperature: 150°C; 4) Mold temperature: 80°C; 5) Dissolving medium: water.

[0032] Wax mold making process is as follows:

[0033] 1) Wax model material: No. K-501 wax, 2) Wax melting temperature: 100°C; 3) Wax injection temperature: 70°C;

[0034] 4) Wax injection pressure: 60Kg / cm 2 ; 5) Holding time: 80S;

[0035] 6) Cooling water temperature: 25°C.

[0036] 2. Manufacture the shell:

[0037] 1) Degreasing and degreasing of modules

[0038] 2) Apply paint and sand on the module:

[0039] Before applying the paint, stir the paint evenly. After the paint is applied, sanding is carried out. Surface layer: silica sol with 320 mesh zirc...

Embodiment 2

[0048] The heat-resistant steel exhaust manifold of automobile engine adopts investment casting process and steps as follows:

[0049] 1. Manufacture of wax mold: using soluble urea core method,

[0050] The core manufacturing process is as follows:

[0051] 1) Core material: urea; 2) Molding method: free casting;

[0052] 3) Melting temperature: 100°C; 4) Mold temperature: 50°C; 5) Dissolving medium: water.

[0053] Wax mold making process is as follows:

[0054] 1) Use K-501 wax, 2) Wax melting temperature: 80°C; 3) Wax injection temperature: 50°C;

[0055] 4) Wax injection pressure: 20Kg / cm 2 ; 5) Holding time: 20S;

[0056] 6) Cooling water temperature: 5°C.

[0057] 2. Manufacture the shell:

[0058] 1) Degreasing and degreasing of modules

[0059] 2) Apply paint and sand on the module:

[0060] Before applying the paint, stir the paint evenly. After the paint is applied, sanding is carried out. Surface layer: silica sol with 320 mesh zirconium powder, dried fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com