Catalyst for catalytic conversion of biological cellulose and preparation method and applications of catalyst

A technology for catalytic conversion and cellulose, applied in physical/chemical process catalysts, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the limitations of large-scale production, high catalyst costs, and complex operations And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Catalyst preparation: according to mass ratio CuO / ZnO / Al 2 o 3 =10%:40%:50%, take corresponding amount of copper nitrate, aluminum nitrate, zinc nitrate, be dissolved in deionized water, form the solution that total metal ion concentration is 0.25mol / L. Weigh a certain amount of sodium carbonate powder and dissolve it in deionized water to form a sodium carbonate solution with a concentration of 0.25mol / L. Drop metal salt solution and sodium carbonate solution into deionized water at 60°C at the same time, stir vigorously while adding dropwise, keep the pH between 6 and 7, and age the resulting suspension at 60°C for 2 hours, filter, wash, and dry , and then calcined at 600° C. for 5 h to obtain a metal oxide catalyst.

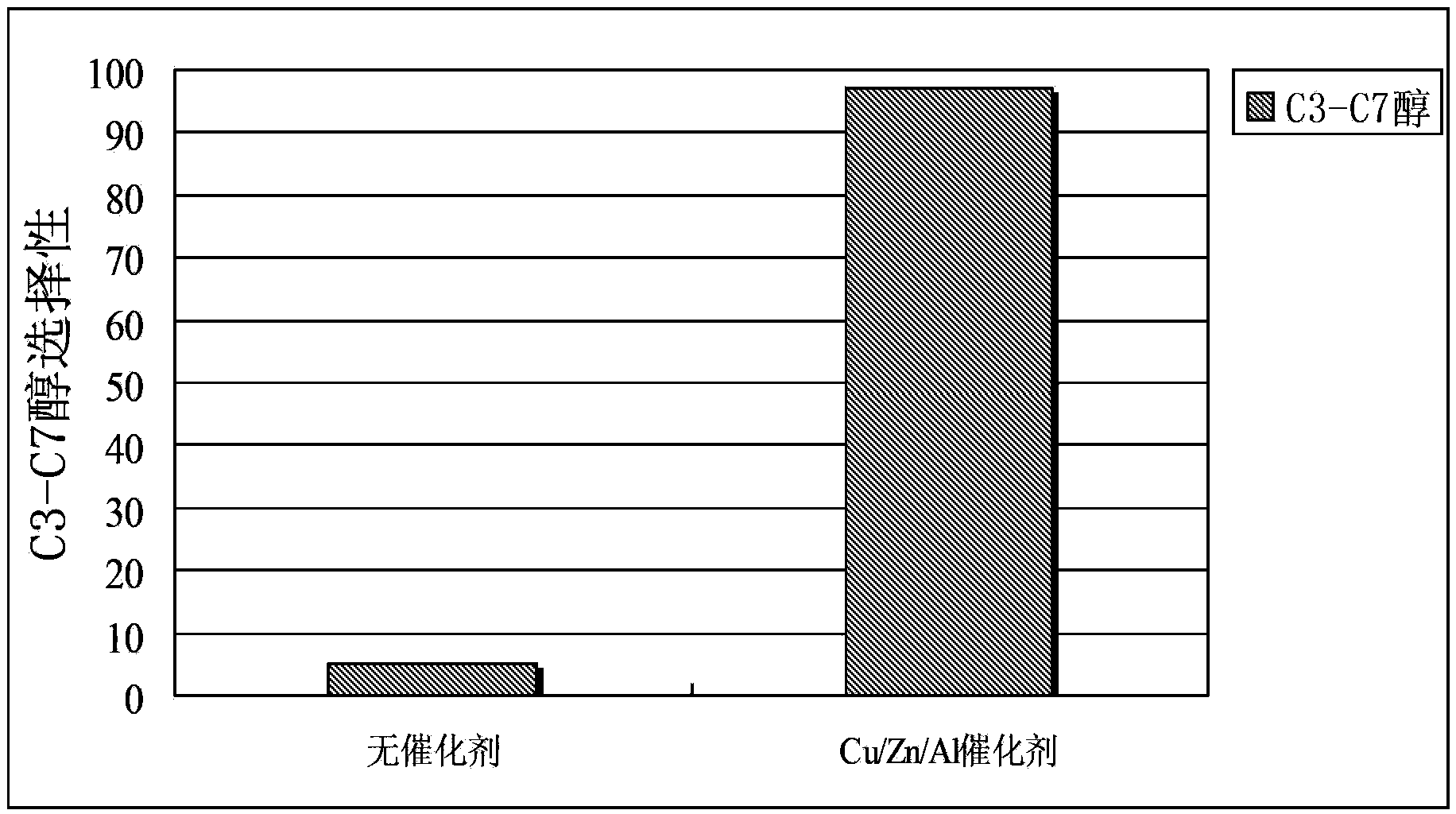

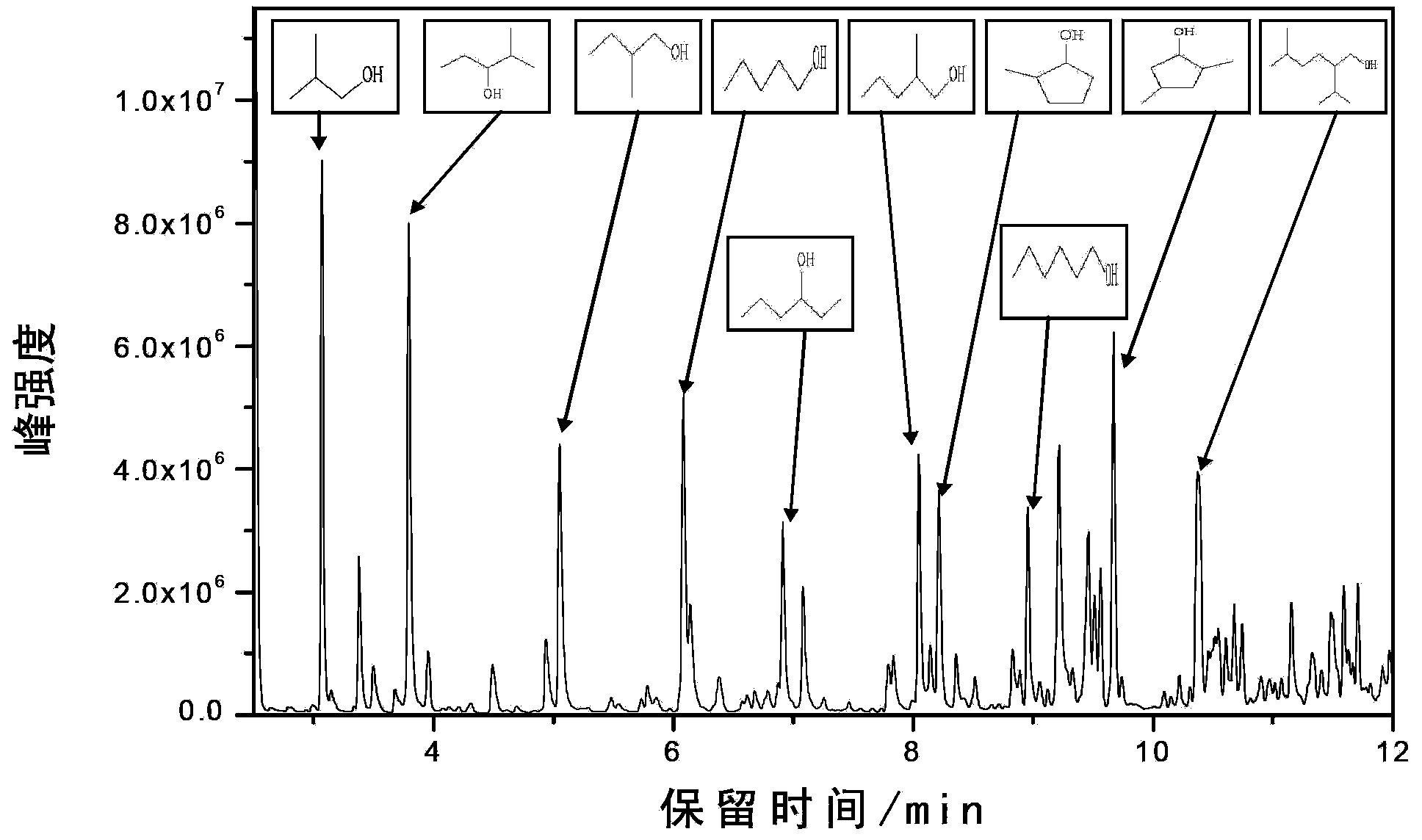

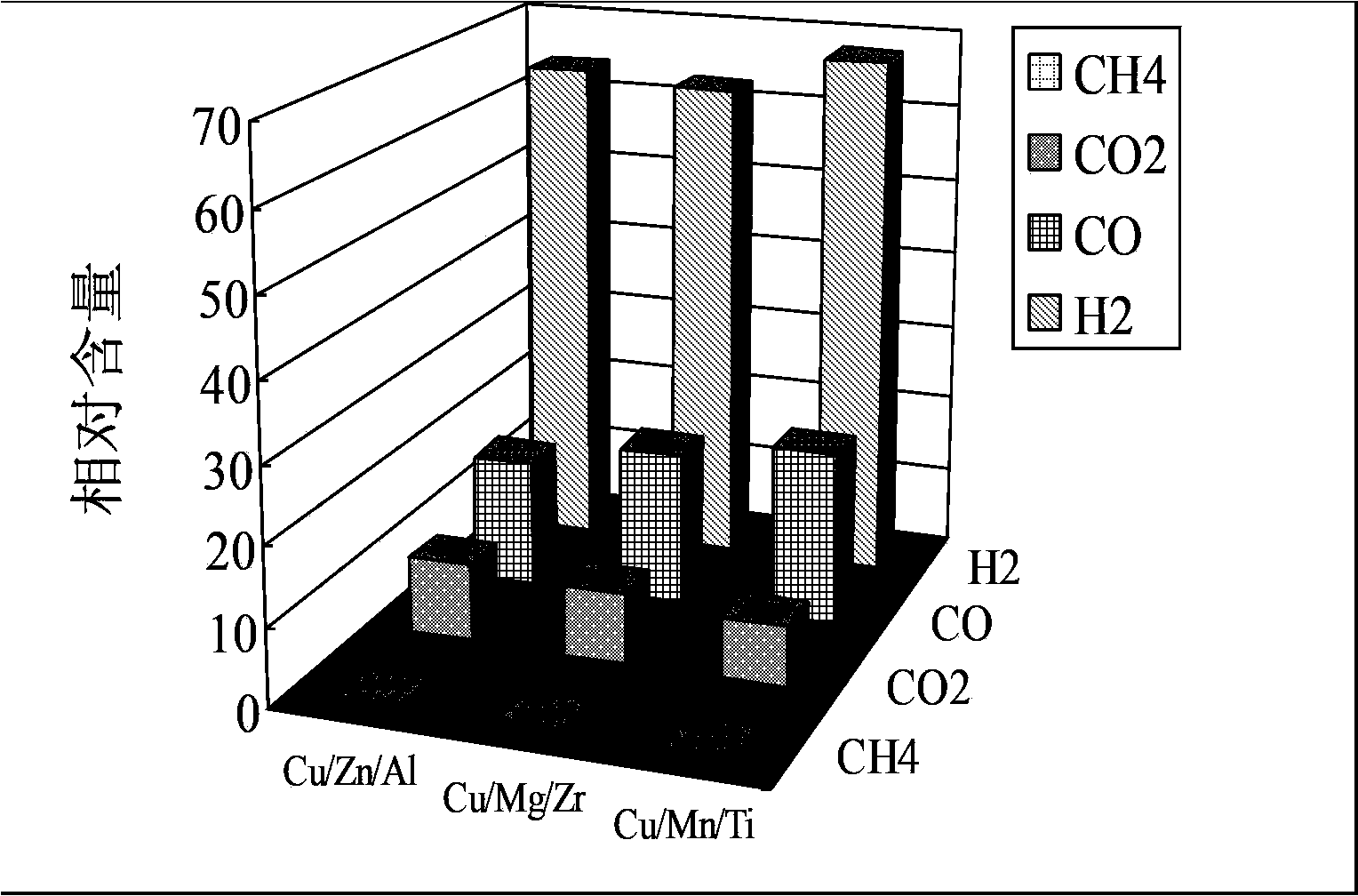

[0063] Catalyst performance evaluation: in methanol medium, for CuO / ZnO / Al 2 o 3 The metal oxide catalysts were evaluated for activity. Add 0.25g catalyst, 0.5g microcrystalline cellulose, and 30mL methanol into a 100mL airtight autoclave, and use ...

Embodiment 2

[0065] Catalyst preparation: according to mass ratio CuO / MgO / ZrO 2 =30%:30%:40%, take corresponding amount of copper chloride, magnesium chloride, zirconium chloride, be dissolved in deionized water, form the solution that total metal ion concentration is 1mol / L. A certain amount of urea powder was weighed and dissolved in deionized water to form a urea solution with a concentration of 2 mol / L. Drop metal salt solution and urea solution into deionized water at 100°C at the same time, stir vigorously while adding dropwise, keep the pH between 7 and 8, and age the resulting suspension at 100°C for 1 hour, filter, wash, and dry. Then calcined at 400° C. for 10 h to obtain a metal oxide catalyst.

[0066] Catalyst performance evaluation: in methanol medium, for CuO / MgO / ZrO 2 The metal oxide catalysts were evaluated for activity. Add 0.25g catalyst, 2g lignin extract, and 30mL methanol into a 100mL airtight autoclave, and use N 2The air in the autoclave was replaced. The autoc...

Embodiment 3

[0068] Catalyst preparation: according to mass ratio CuO / MnO 2 / TiO 2 =60%:15%:25%, take corresponding amount of copper acetate, manganese acetate, titanium acetate, be dissolved in deionized water, form the solution that total metal ion concentration is 5mol / L. A certain amount of potassium carbonate powder was weighed and dissolved in deionized water to form a potassium carbonate solution with a concentration of 5 mol / L. Drop metal salt solution and potassium carbonate solution into deionized water at 60°C at the same time, stir vigorously while adding dropwise, keep the pH between 5 and 7, and age the resulting suspension at 60°C for 5 hours, filter, wash, and dry , and then calcined at 500° C. for 6 h to obtain a metal oxide catalyst.

[0069] Catalyst performance evaluation: in methanol medium, for CuO / MnO 2 / TiO 2 Catalysts were evaluated for activity. Add 0.5g of catalyst, 2.5g of hemicellulose extract, and 30mL of methanol into a 100mL closed autoclave, and use N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com