Novel esterification pre-reactor

A technology of pre-reactor and reactor, applied in chemical instruments and methods, organic chemistry, carboxylate preparation, etc., can solve the problems of two-step reaction and separation process difficulties, equipment corrosion, energy consumption and operating costs, etc. Achieve high reaction selectivity and product conversion rate, increase production capacity and product purity, reduce energy consumption and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

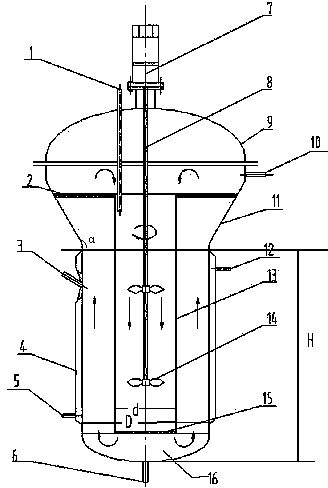

[0017] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

[0018] Such as figure 1 Shown, the present invention is a kind of esterification prereactor, comprises prereactor housing 16, is provided with the feeding pipe 1 that inserts in the described prereactor housing 16 at the upper end of described prereactor housing 16 and the liquid outlet 10, the top of the pre-reactor housing 16 is a loam cake 9, and the upper end of the loam cake 9 is fixedly provided with a motor 7 that drives the shaft 8 to rotate, and the motor 7 is an adjustable frequency conversion motor, Adjust the rotating speed to make the catalyst just suspend without causing most of the catalyst to enter the upper part of the draft pipe 13 or be dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com