Disproportionated rosinyl anion/non-ion composite surfactant and preparation method thereof

A composite surfactant and non-ionic surface technology, applied in the direction of chemical instruments and methods, chemical/physical processes, dissolution, etc., to achieve the effect of low product toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

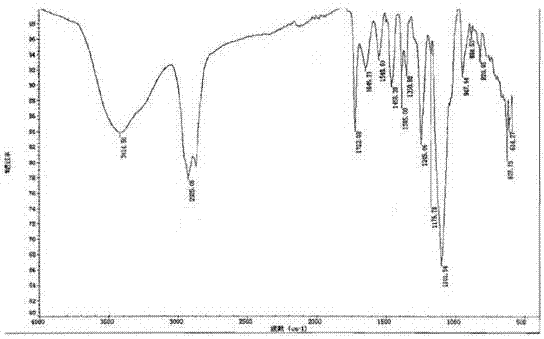

Image

Examples

Embodiment 1

[0019] A disproportionated rosin anion / nonionic composite surfactant, wherein the molecular weight of polyethylene glycol is any one of 200, 400, 600, 1000, 2000, 4000, and the sulfonate is any one of sodium salt or calcium salt .

[0020]

Embodiment 2

[0022] Weigh disproportionated rosin and polyethylene glycol 400 with a molar ratio of 2:1 and pour them into a 500mL four-neck flask, then add 0.2% zinc oxide as a catalyst, heat to 270°C to make it fully react, and wait for the acid value to drop. To about 10, the reaction is basically complete, cooled to 40 ℃. Add the sulfonating agent concentrated sulfuric acid dropwise in the water bath (the molar ratio of rosin to sulfonating agent is 1: 1.2) and react at 40-60°C for 4-6 hours, add enough sodium hydroxide solution to neutralize to PH=7, Raise the temperature to 80°C, stir and react for 1-2 hours, and evaporate the water generated by the reaction to obtain the product.

[0023]

Embodiment 3

[0025] Weigh disproportionated rosin and polyethylene glycol 600 with a molar ratio of 2:1 and pour them into a 500mL four-neck flask, then add 0.1% zinc oxide as a catalyst, heat to 280°C to make it fully react, and wait for the acid value to drop. To about 10, the reaction is basically complete, cooled to 40 ℃. Add the sulfonating agent concentrated sulfuric acid dropwise in the water bath (the molar ratio of rosin to sulfonating agent is 1: 1.3) and react at 40-60°C for 4-6 hours, add enough calcium hydroxide solution to neutralize to PH=7, Raise the temperature to 80°C, stir and react for 1-2 hours, and evaporate the water generated by the reaction to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension value | aaaaa | aaaaa |

| Critical micelle concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com