Low-protein nutrition crispy slices and making method thereof

A low-protein, nutritious technology, applied in the field of food processing, can solve the problem of single food types, etc., and achieve the effect of easy digestion and absorption, avoiding diseases, crispy and delicious digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] According to a typical implementation of the present invention, the low-protein nutritional crisps include the following raw materials in parts by weight: 90-95 parts of edible starch, 0.5-10 parts of sucrose, 0.5-3 parts of malt extract, 0.5-2 parts of salt, 0.2-0.8 parts of monoglyceride, 0.2-0.8 parts of double-effect baking powder.

[0024] The low-protein nutritional crisps prepared by using edible starch as the main raw material and using sucrose, malt extract, salt, monoglyceride, double-effect baking powder, etc. as auxiliary materials are rich in nutrition, crunchy and delicious, and easy to digest and absorb. The low-protein nutritional crisps can be used as a staple food for breakfast or as a daily snack food. It can not only control the protein intake of renal failure, uremia and other kidney disease patients and PKU patients, but also provide them with enough calories. Help patients develop the habit of low-protein diet. The occurrence and exacerbation of ...

Embodiment 1

[0044] Raw material formula: corn starch: 90 parts by weight, sucrose: 10 parts by weight, malt extract: 0.5 parts by weight, salt: 0.5 parts by weight, monoglyceride: 0.2 parts by weight, double-acting baking powder: 0.5 parts by weight.

[0045] The raw materials in the above parts by weight were mixed uniformly by a mixer and then transported to the extruder by a screw conveyor. At the same time, 15 parts by weight of water and 0.5 IU of α-amylase were added to the II zone of the extruder. The temperature in each temperature zone of the extruder was adjusted to be 65°C in zone II, 125°C in zone III, 115°C in zone IV, 80°C in zone V, and 75°C in zone VI, and the screw speed was 220r / min. The temperature of the die head is adjusted to 80°C, the cutting speed is 1300r / min, and the extruded semi-finished product is cut. After cutting, the spherical semi-finished product is transported to a fluidized bed at 60°C for drying until the moisture content of the semi-finished product i...

Embodiment 2-6

[0047] Its preparation steps are the same as in Example 1, the difference lies in the proportioning of raw materials.

[0048] The proportioning of table 1 raw material

[0049]

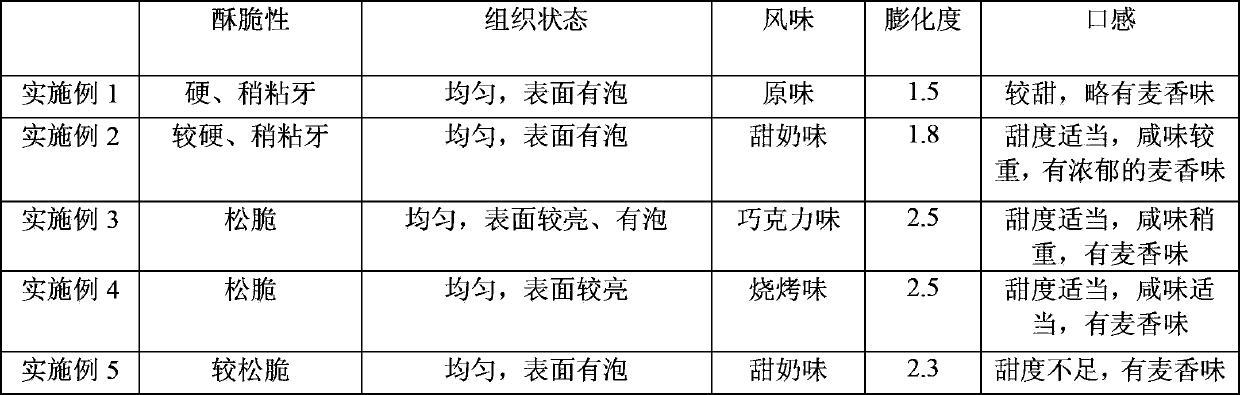

[0050] Table 2 Product sensory indicators

[0051]

[0052]

[0053] Table 3 Nutritional components of low-protein nutritional crisps (content per 100 grams)

[0054]

[0055] It can be seen from the sensory index and table and nutritional composition table of the low-protein nutritional crisps in Table 2 that the sensory evaluation of the low-protein nutritional crisps prepared in the examples of the present invention is better, and the nutrition is balanced. In particular, the low-protein nutritional chips prepared in Example 4 have appropriate sweetness, appropriate saltiness, wheat flavor, crisp mouthfeel, uniform texture, brighter surface, and no air bubbles; balanced nutritional components, easy to digest, and low protein (less than 1.0%) and low production ingredients, it is a be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com