Black tea extract for effectively retaining original tea aroma and taste and preparation method and application of same

A technology for extract and aroma of black tea, applied in the field of extract of black tea and its preparation, can solve problems such as proportion distortion, single component, weak tea aroma, etc., and achieve the effects of reducing loss, strong taste, and red-colored soup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0022] The aroma volatile oil component comprises 10-45% of linalool and 10-35% of linalool oxide, accounting for 10-45% by mass of the aroma volatile oil component.

[0023] The linalool oxides include 1-15% cis-pyran-linalool oxides or / and 5-20% trans-pyran-linalool oxides or / And 2~10% cis furan type linalool oxide or / and 2~20% trans furan type linalool oxide.

[0024] The aroma volatile oil component comprises 0.5-5% methyl salicylate and / or 2-11% geraniol and / or 8-28% phenylacetaldehyde, accounting for the mass percentage of the aroma volatile oil component.

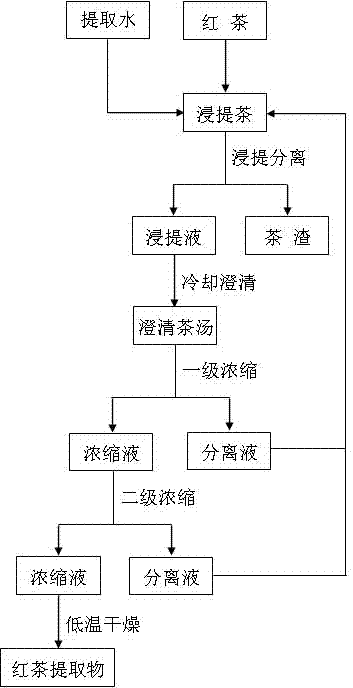

[0025] Such as figure 1 As shown, the preparation method of the black tea extract that effectively retains the aroma and taste of the original tea described in the present invention includes tea extraction, cooling and clarification, primary concentration, secondary concentration, and low-temperature drying, specifically:

[0026] A. Tea extraction: Put the raw tea leaves into the extraction tank, add extraction w...

Embodiment 1

[0041] Take 15kg of black tea to remove impurities, put it into an ultrasonic-assisted percolation extraction tank after rinsing, add 15 times the volume of distilled water and extract at a temperature of 65°C for 1.3 hours, separate the tea soup to obtain an extract; naturally cool the extract to 30°C , and filtered through a microfiltration membrane with a pore size of 0.5 μm to obtain clarified tea soup; the clarified tea soup was concentrated and separated through a 0.001 μm reverse osmosis membrane to obtain a primary concentrate and separation liquid; the primary concentrate was concentrated and separated through a nanofiltration membrane with a pore size of 0.5 μm, Obtain 18.4kg of the secondary concentrate with a solid content of 14.7%. The secondary concentrate is sent to a vacuum freeze-drying device for drying to obtain 2.7kg of freeze-dried black tea extract.

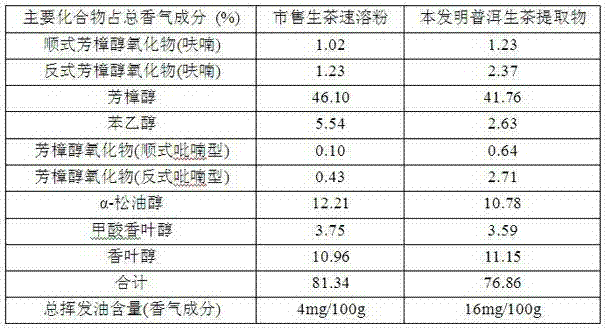

[0042] Determination test: take the black tea extract prepared in Example 1, and measure its aroma compone...

Embodiment 2

[0047] Take 20kg of black tea to remove impurities and put it into an electromagnetic wave extraction tank, add 10 times the volume of demineralized water and extract at a temperature of 45°C for 2 hours, separate the tea soup to obtain an extract; cool the extract to 10°C by electric refrigeration, and pass through The clarified tea infusion is obtained by filtration through a fine filter membrane with a pore size of 5 μm; the clarified tea infusion is concentrated and separated by a 0.0001 μm reverse osmosis membrane to obtain a primary concentrate and separation liquid; the primary concentrate is distilled and concentrated through a membrane with a pore size of 0.1 μm to obtain a solid content of 16.8 kg 21.6% secondary concentrate; the secondary concentrate is sent to a microwave vacuum drying device for drying to obtain 3.6kg black tea extract.

[0048] Using the detection method in Example 1, the prepared black tea extract was tested, and the result was: the mass percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com