Method for manufacturing industrialized high-energy lithium iron phosphate material

A lithium iron phosphate, high-energy technology, applied to electrical components, battery electrodes, circuits, etc., can solve problems such as complex process, poor material compaction performance, and difficulty in making high-capacity batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

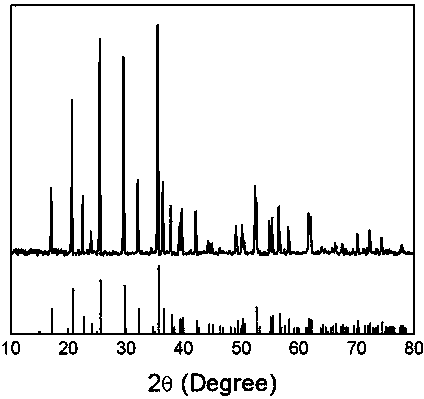

Image

Examples

Embodiment 1

[0030] Example 1 (comparative example): Lithium salt, iron salt, and phosphorus salt were mixed according to the molar ratio of 1.01:1:1, and then 10% polyethylene glycol and 1% nickel nitrate were added, and the total mass of the solution was 400kg. In the ball mill for the first wet ball milling, the particle size is measured by MalvernMS2000 laser particle size analyzer to be 600nm-1200nm; a centrifugal spray granulation dryer is used, the inlet temperature is 240°C, and the outlet temperature is 100°C to obtain a spherical precursor; The precursor was put into a gas circulation furnace for sintering under the protection of nitrogen, and pre-fired at a constant temperature of 400°C for 5 hours; after the pre-fired precursor was ball milled and spray-dried, it was sintered under the protection of nitrogen at a constant temperature of 700°C for 5 hours.

[0031] Preparation of negative electrode material: with MCMB: acetylene black: polyvinylidene fluoride = 92wt%: 3wt%: 7wt% ...

Embodiment 2

[0036]Example 2 (comparative example): Lithium salt, iron salt, and phosphorus salt were mixed according to the molar ratio of 1.01:1:1, and then 10% polyethylene glycol and 1% nickel nitrate were added, and the total mass of the solution was 400kg. In the second wet ball milling in the ball mill, the particle size was measured by Malvern MS2000 laser particle size analyzer to be 50nm~500nm; a centrifugal spray granulation dryer was used, the inlet temperature was 240°C, and the outlet temperature was 100°C to obtain a spherical precursor; The precursor is put into a gas circulation furnace for sintering under the protection of nitrogen, and pre-fired at 400°C for 5 hours; after the pre-fired precursor is ball milled and spray-dried for the third time, it is sintered at 700°C for 5 hours under the protection of nitrogen. . The battery production is the same as in Example 1.

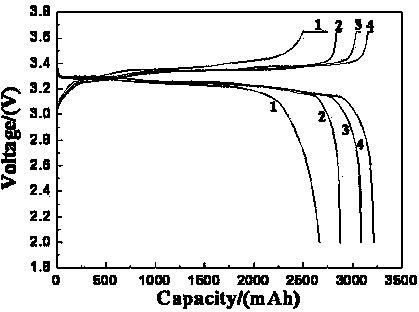

[0037] figure 1 To make the first charge and discharge curve of IFR 26650 battery at 0.2C.

Embodiment 3

[0038] Embodiment 3: A kind of preparation method of industrialized high-energy lithium iron phosphate material of this example is characterized in that described method comprises:

[0039] a. Add lithium salt, iron salt, phosphorus salt and mix in bead mill, wherein Li:Fe:P molar ratio is 1.01:1:1, add the polyethylene glycol of mass percentage 10% and the nickel nitrate of 1% again, the solution total The mass is 400kg, and the first wet ball milling is carried out, and the particle size is measured by a MalvernMS2000 laser particle size analyzer to be 600nm-1200nm. After the ball milling is completed, it is taken out for use;

[0040] b. Repeatedly add lithium salt, iron salt, and phosphorus salt of the same type and quality as step a into the bead mill and mix, then add polyethylene glycol and nickel nitrate of the same type and quality as step a, and the total mass of the solution is 400kg , carry out the second wet ball milling, measure its particle diameter by Malvern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com