Preparation method of gold-tin alloy solder foil

A technology of tin alloy and foil materials, which is applied in the field of preparation of gold-tin alloy solder foil materials, can solve problems such as poor brazing performance, low production efficiency, and slow temperature response of gold-tin solder brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Prepare fine-tuned gold-tin alloy raw materials, with a tin content of 20.2wt% and a gold content of 79.8wt%. It is melted in a graphite crucible and poured into a graphite mold at 300°C. The ingot is taken out and subjected to homogenization heat treatment at a temperature of 220°C. The heat treatment time 30~80 minutes. The ingot is then hot-rolled at 220°C, the deformation of each pass is controlled 5 minutes, and the final rolling thickness is 0.1mm.

Embodiment 2

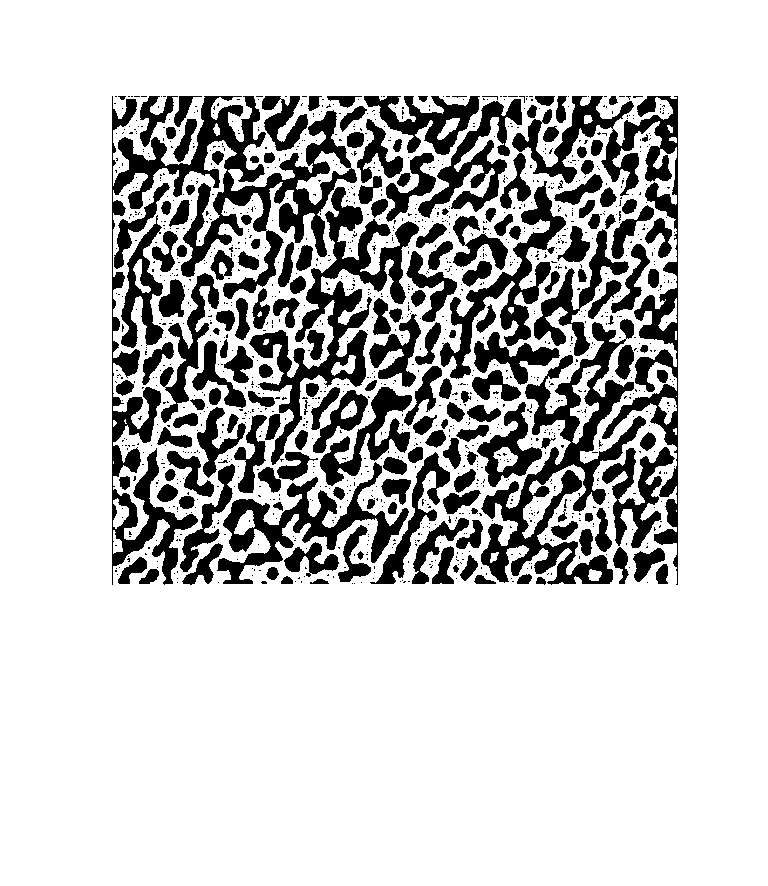

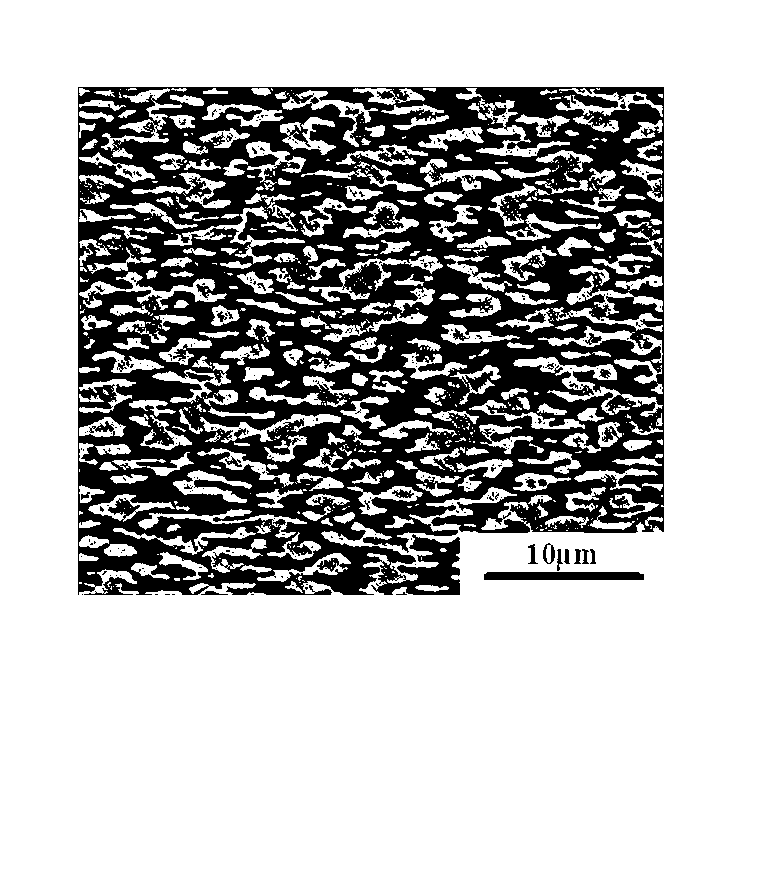

[0018] Prepare fine-tuned gold-tin alloys, in which the tin content is 20.5wt%, and the gold content is 79.5wt%. It is melted in a graphite crucible and poured into a cold graphite mold at 340°C. The ingot is taken out and subjected to homogenization heat treatment at a temperature of 240°C. The time is 30~60 minutes, the microstructure of the ingot after homogenization heat treatment is as follows: figure 1 As shown, it is a uniform and fine two-phase eutectic structure. The ingot is then hot-rolled at 240°C, the deformation of each pass is controlled to be less than 30%, the intermediate annealing time is more than 5 minutes, and the final rolling thickness is 0.05mm. figure 2 Shown is the microstructure of the gold-tin alloy solder foil.

Embodiment 3

[0020] Prepare fine-tuned gold-tin alloys, in which the tin content is 20.7wt%, and the gold content is 79.3wt%. It is melted in a graphite crucible and poured into a cold graphite mold at 360°C. The ingot is taken out and subjected to homogenization heat treatment at a temperature of 260°C. Time 10~60 minutes. The ingot is then hot-rolled at 240°C, the deformation of each pass is controlled 5 minutes, and the final rolling thickness is 0.02mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com