Electric packing machine

An electric and battery technology, which is applied to the parts of the strapping machine and strapping materials, etc., can solve the problems of damage to the bundled objects, increase the restriction, and work blockage, etc., and achieve strong packing fastness, compact structure, and compact structure strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

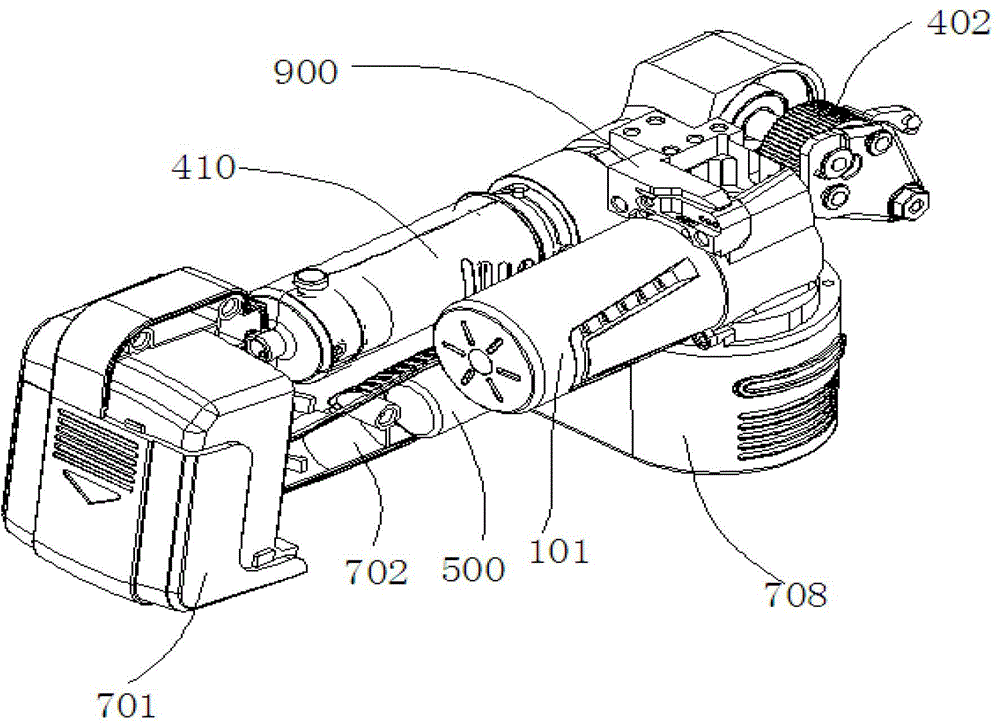

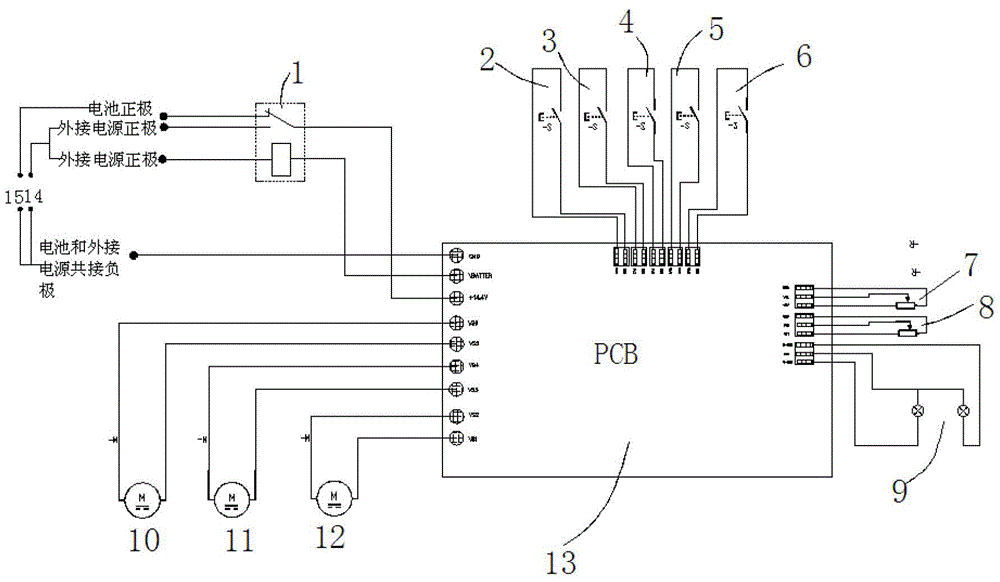

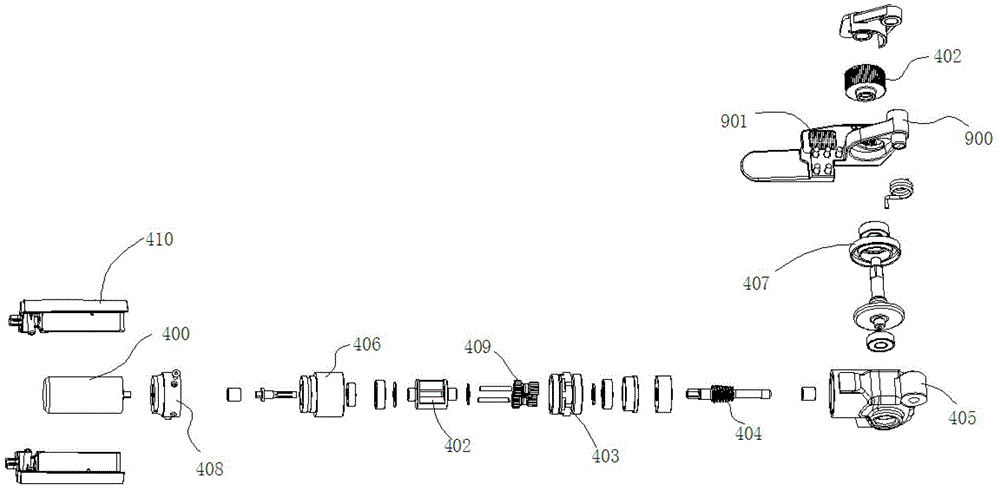

[0027] refer to figure 1 An electric baler, comprising a battery 700, a body, a handle 702, a tensioning device, a tape cutting device, a welding device and a control board, the control board 13 is provided with a relay, and a bottom plate 900 is fixed at the lower part of the body, the bottom board The 900 is equipped with a welding tooth plate and a 901 tensioning tooth plate, refer to image 3 , 4 and 5,: the tensioning device includes a tensioning motor 400, a reduction box 405 and a tensioning wheel 402, the tensioning motor 400 is placed in the handle 702 and is connected with the reduction box 405 through a connecting sleeve 406, and the pulling The tight wheel 402 is connected to the reduction box 405, and the reduction box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com