Inter-low-permittivity layer insulating film, and method for forming inter-low-permittivity layer insulating film

A technology of low dielectric constant layer and film-forming method, which is applied in coatings, circuits, electrical components, etc., can solve problems such as poor adhesion, reduced wiring reliability, and weak cohesive energy, and achieve barrier and tightness Improvement of compatibility, improvement of low dielectric constant, and suppression of insulation breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

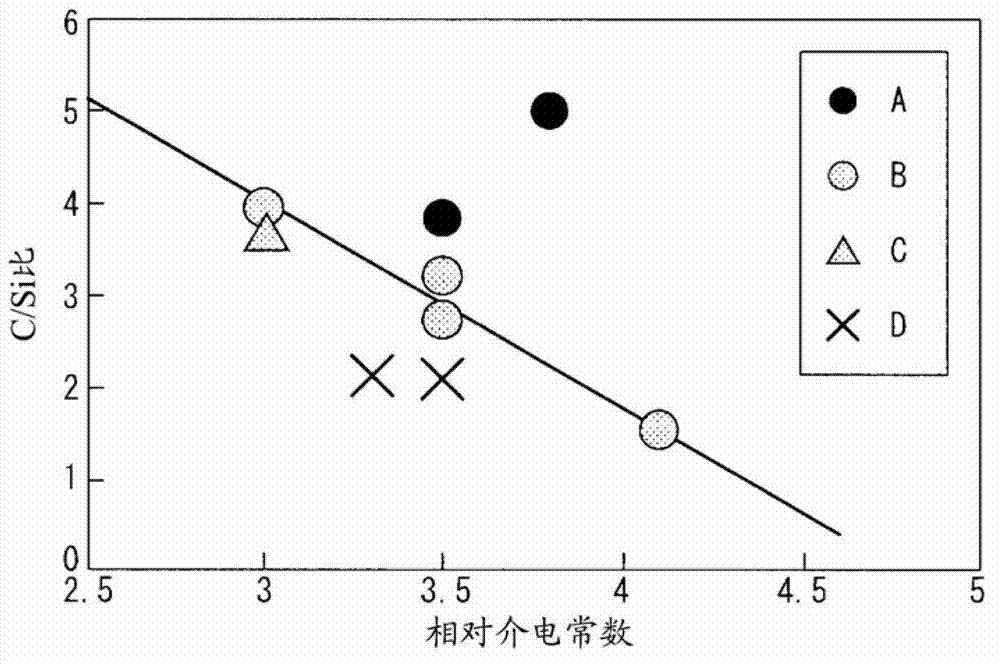

[0070] In Example 1, using isobutyltrimethylsilane (iBTMS) as the insulating film material, a SiCH film was formed under the conditions of a flow rate of 20 sccm, a pressure of 3 Torr, and a plasma output power of 550 W. As a result, a SiCH film with a relative dielectric constant of 3.5 was obtained . The ratio of carbon to silicon (C / Si ratio), porosity, barrier properties, and adhesiveness were evaluated, and the results are shown in Table 1.

[0071] From this result, it can be seen that in the low dielectric constant interlayer insulating film of Example 1, the C / Si ratio is large, and thus the porosity is small. In addition, it can be seen that the barrier properties are equal to those of known interlayer insulating films.

Embodiment 2

[0073] In Example 2, diisobutyldimethylsilane (DiBDMS) was used as the insulating film material, and the SiCH film was formed under the conditions of a flow rate of 20 sccm, a pressure of 3 Torr, and a plasma output power of 650 W. As a result, SiCH with a relative dielectric constant of 3.5 was obtained. membrane. The ratio of carbon to silicon (C / Si ratio), porosity, barrier properties, and adhesiveness were evaluated, and the results are shown in Table 1.

[0074] From this result, it can be seen that in the low dielectric constant interlayer insulating film of Example 2, the C / Si ratio is large, so the porosity is small. In addition, it can be seen that the barrier property is equal to that of a known interlayer insulating film, and the adhesiveness is superior to that of a known interlayer insulating film.

Embodiment 3

[0076] In Example 3, diisobutyldimethylsilane (DiBDMS) was used as an insulating film material, and a SiCH film was formed under the conditions of a flow rate of 20 sccm, a pressure of 3 Torr, and a plasma output power of 450 W. As a result, SiCH with a relative dielectric constant of 3.0 was obtained. membrane. The ratio of carbon to silicon (C / Si ratio), porosity, barrier properties, and adhesiveness were evaluated, and the results are shown in Table 1.

[0077] From this result, it can be seen that in the low dielectric constant interlayer insulating film of Example 3, the C / Si ratio is large, so the porosity is small. In addition, it can be seen that although the barrier property is slightly inferior to that of the known interlayer insulating film, the adhesion property is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com